Production method of long carbon chain dibasic acid

A long-chain dibasic acid and production method technology, which is applied in the field of bioengineering, can solve the problems of slow development of downstream products of long-chain dibasic acid, backward production technology and equipment, and failure to meet customer needs, etc., and achieve a step-by-step reduction Effects of cultivation process, shortened production cycle, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

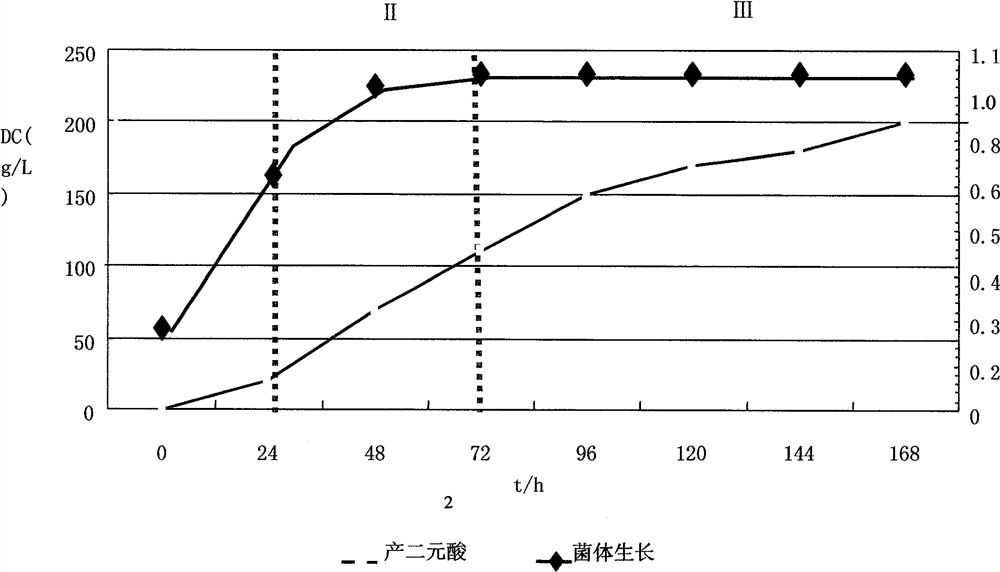

Image

Examples

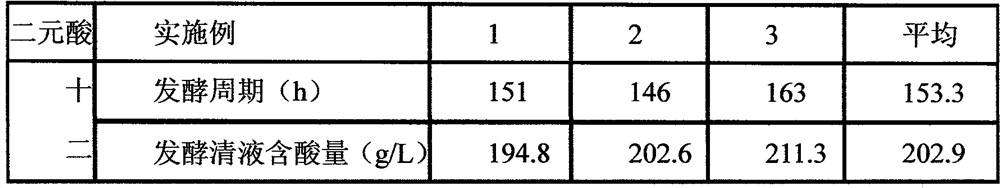

Embodiment 1

[0047]Fermentation control conditions:

[0048]Volume: 8%, can temperature: 25 ° C, ventilation ratio: 1: 0.3VVM, tank pressure: 0.08MPa, pH: 1 post-addition hydrocarbon 4.0, after adding alkanes: 120 hours.

[0049]Replenishment control parameters:

[0050]Alkane: When the growth concentration of the bacteria is greater than (OD6200.8, start supplementing cell regulators and alkanes, adding cellular regulators disposable, and alkane control concentration in fermentation broth is 3%, and the feed is stopped 20 hours before fermentation.

[0051]The extraction process of the fermentation liquid:

[0052]The fermentation broth was heated to a fermentation liquid storage tank by a steam heater to 70 ° C. After the liquid, the alkali is added to the fermentation fluid pH to 8.5 to 8.5 to which the membrane is separated by the membrane filtration. The dibasic acid is added to the active carbon. After 50 ° C for 40min, then filtrate to obtain concentrated sulfuric acid to acidification PH2.5, 80 ° C was...

Embodiment 2

[0056]Fermentation control conditions:

[0057]The amount of inoculation: 10%, tank temperature: 30 ° C, ventilation ratio: 1: 0.5VVM, tank pressure: 0.10 MPa, pH: 5.0 before the sinking hydrocarbon 5.5, 7.5, Culture time: 140 hours.

[0058]Replenishment control parameters:

[0059]Alkane: When the growth concentration of the bacteria is greater than (OD6200.8, starting to supplement cell regulators and alkanes, add cell regulators for one-time addition, and alkane control concentration in fermentation broth is 7%, and the feed is stopped 20 hours before fermentation.

[0060]The extraction process of the fermentation liquid:

[0061]The fermentation broth was heated to a fermentation liquid tank by a steam heater to 70 to 90 ° C. After the liquid, the alkali was added to 9.5, separated by membrane filtration, and a dibasic acid tank was added to 80 min after 65 ° C, and then filtered to obtain a decolorized liquid for concentrated sulfuric acid to pH3. .5, 88 ° C Incubate for 34 hours, acidified...

Embodiment 3

[0065]Fermentation control conditions:

[0066]The amount of inoculation: 20%, can temperature: 35 ° C, ventilation ratio: 1: 0.7VVM, can press: 0.12 MPa, pH: 1.0 before the addition of alkanes, 8.5 after extractance, culture time: 160 hours.

[0067]Replenishment control parameters:

[0068]Alkane: When the growth concentration of the bacteria is greater than (OD6200.8, start supplementing cell regulators and alkanes, adding cellular regulators disposable, and alkane control concentration in fermentation broth is 10%, and the feed is stopped 20 hours before fermentation.

[0069]The extraction process of the fermentation liquid:

[0070]The fermentation broth was heated to a fermentation liquid tank by a steam heater to 70 to 90 ° C. Later, the alkali was added to the fermentation liquid pH to 10.5, separated by membrane filtration, and 1.0% activated carbon was added, and 120 min was decolored by 120 min, and then the decolorized liquid was acidified to pH5. .0, 95 ° C for 4 hours, acidified cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com