Device for producing long carbon chain diacid by biological fermentation process

A long carbon chain dibasic acid and bio-fermentation technology, which is applied in biochemical cleaning devices, enzymology/microbiology devices, bioreactor/fermentation tank combinations, etc., can solve the limitations of application fields, low product grades, production High cost and other problems, to achieve the effect of improving yield and product quality, reducing production cost, and reducing energy consumption for stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

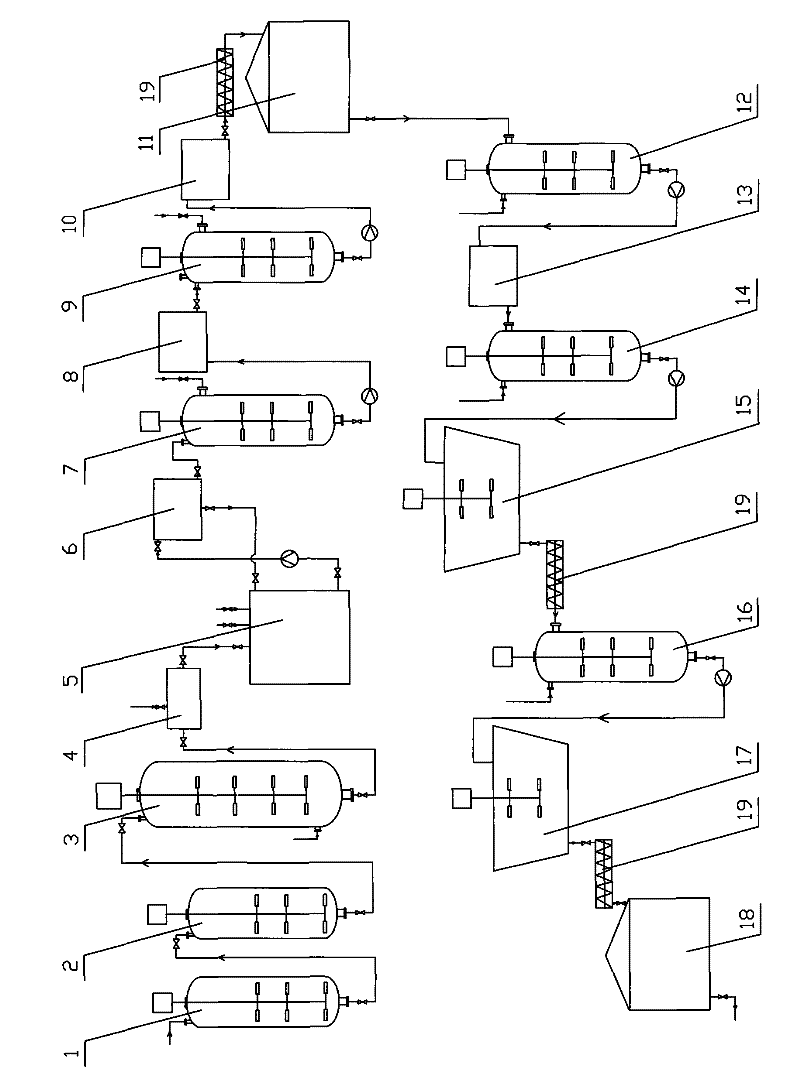

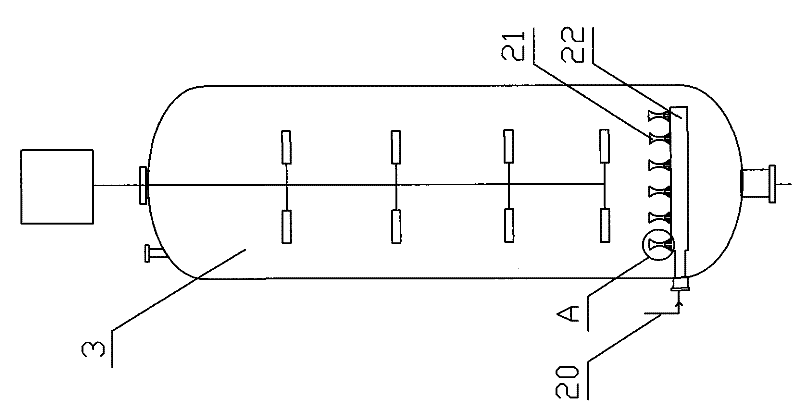

[0024] according to figure 1 As shown, the production device for producing long carbon chain dibasic acid by biological fermentation method, the production device includes a seed tank, a fermentation tank 3, a steam heater 4, a fermentation liquid storage tank 5, a pre-filter 6, a decolorization tank connected in sequence through pipelines Tank I 7, filter I 8, acidification tank 9, filter II 10 and flash dryer I11, with auger 19 between the filter II and flash dryer I11. The seed tank includes a primary seed tank 1 and a secondary seed tank 2 connected by pipelines, and the secondary seed tank 2 is connected with a fermenter 3 .

[0025] The present invention also includes a refining production device, which includes a decolorization tank II 12, a filter III 13, a primary crystallization tank 14, a centrifuge I 15, and a high-temperature water crystallization tank that are sequentially connected to the flash dryer I through pipelines 16. Centrifugal separator II 17 and flash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com