Method for lowering installation height of Ruhstahl Hausen (RH) vacuum processing device under low rail surface elevation condition

A technology of vacuum treatment device and installation height, applied in the field of steelmaking RH process, can solve the problems of insufficient elevation of the crane rail surface, inability to meet the requirements for setting the alloy feeding device and the top-blowing oxygen lance device at the treatment position, etc. Rail surface elevation, short refining cycle, and the effect of meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

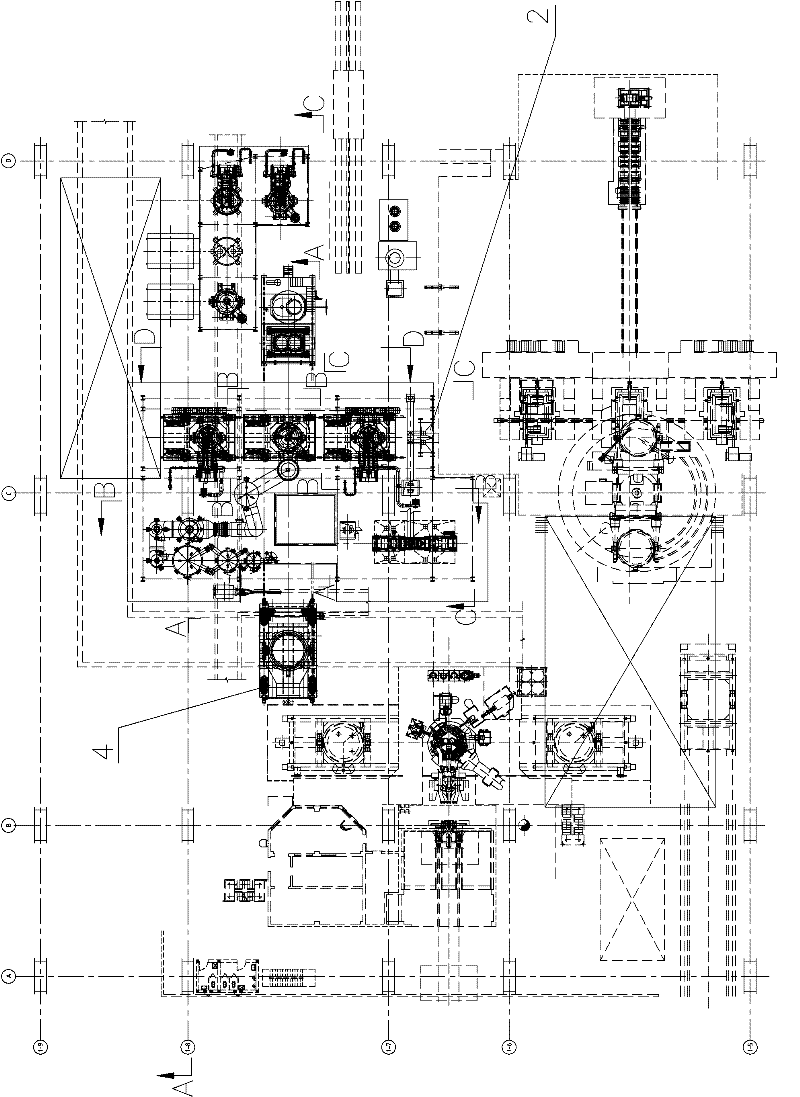

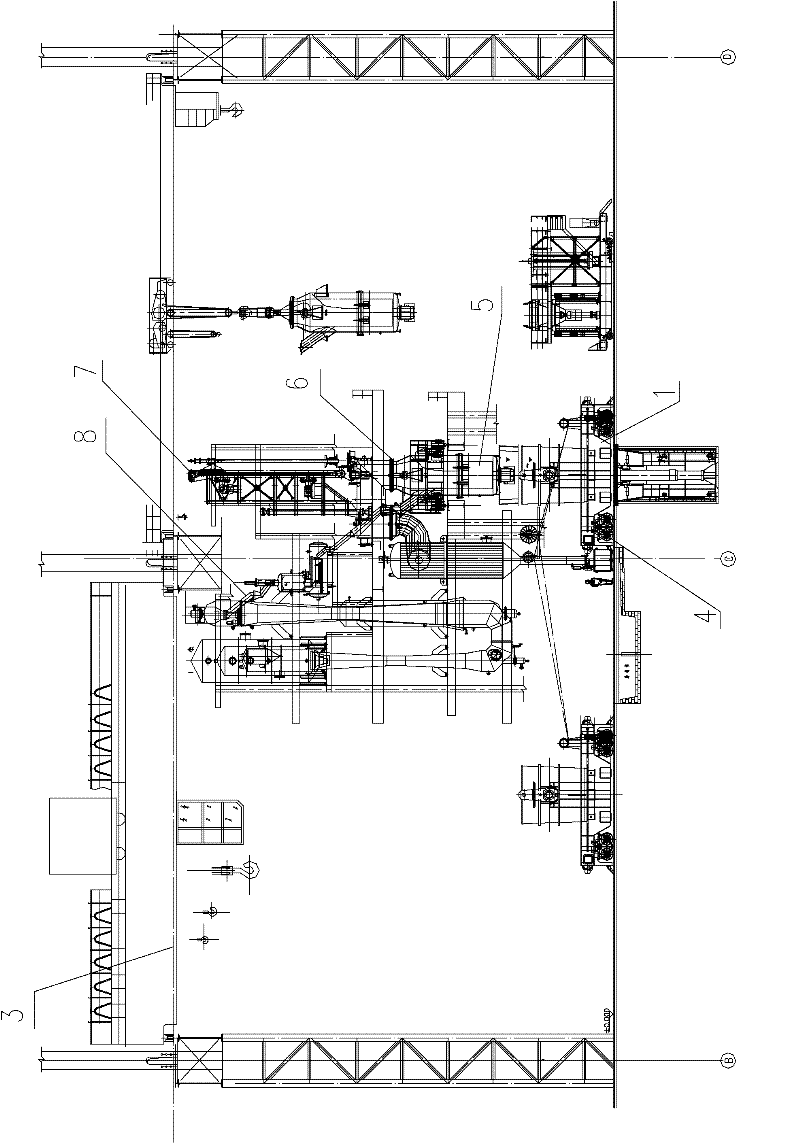

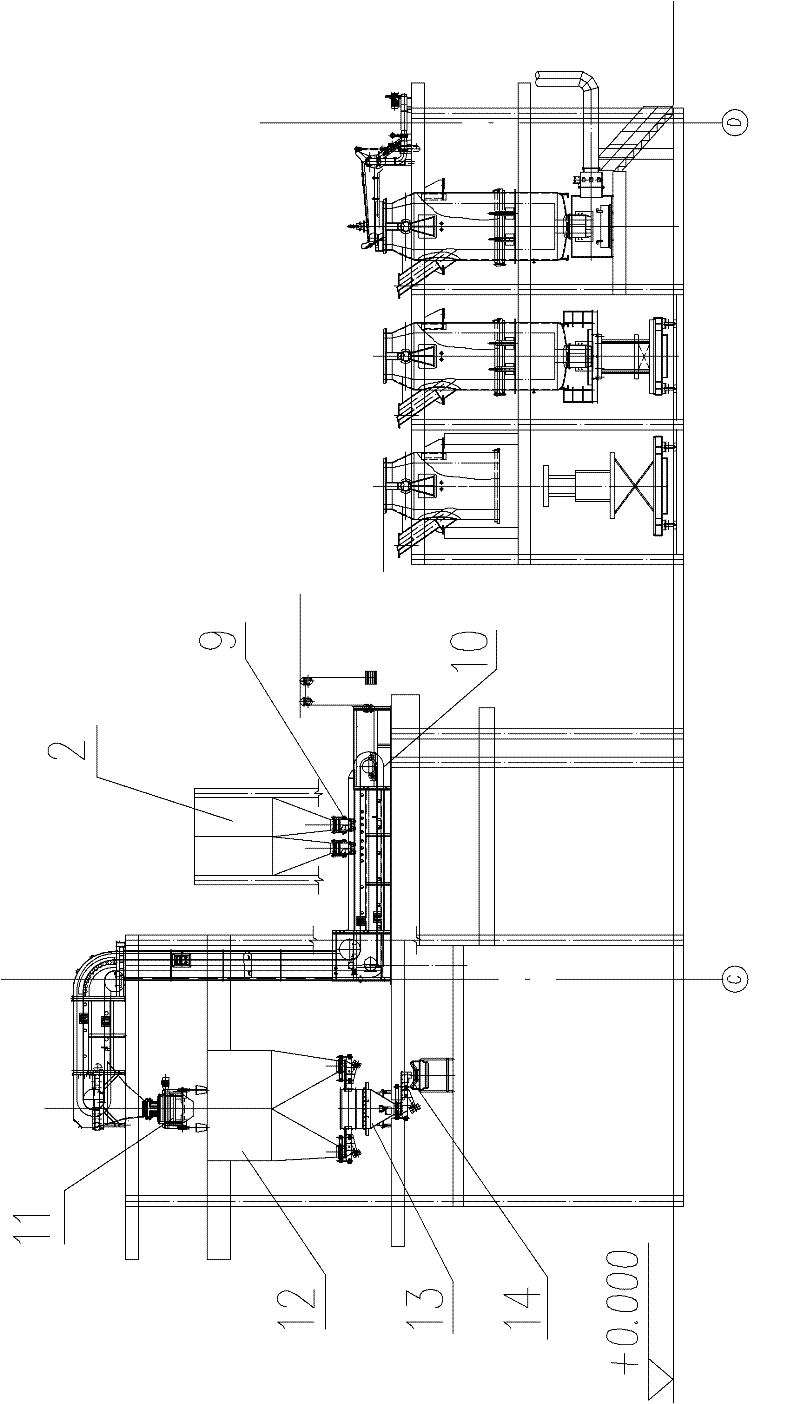

[0025] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the RH vacuum treatment device is mainly composed of alloy feeding system, feeding system, vacuum pump system, RH ladle car jacking device, RH ladle car 4 and ladle, vacuum chamber replacement trolley, vacuum chamber 5, top blowing oxygen lance and feeding The wire system is composed of: the alloy feeding system is arranged near the 1-7 line of the CD auxiliary span, the feeding system is arranged between the 1-6 line and the 1-7 line of the BC molten steel receiving span, and the vacuum pump system is arranged at the BC molten steel receiving span 1 - On both sides of Line 8, RH ladle car jacking device (RH ladle jacking frame), RH ladle car 4 and ladle, vacuum chamber replacement trolley, vacuum chamber and top blowing oxygen lance are arranged on CD auxiliary span RH in sequence from bottom to top For the RH processing position in the ladle car track, the wire feeding system is arranged above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com