Irradiation method of LED

A reflection area and horizontal direction technology, applied in the field of LED irradiation, can solve problems such as glare easily, and achieve the effects of improving light source utilization, improving user experience, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

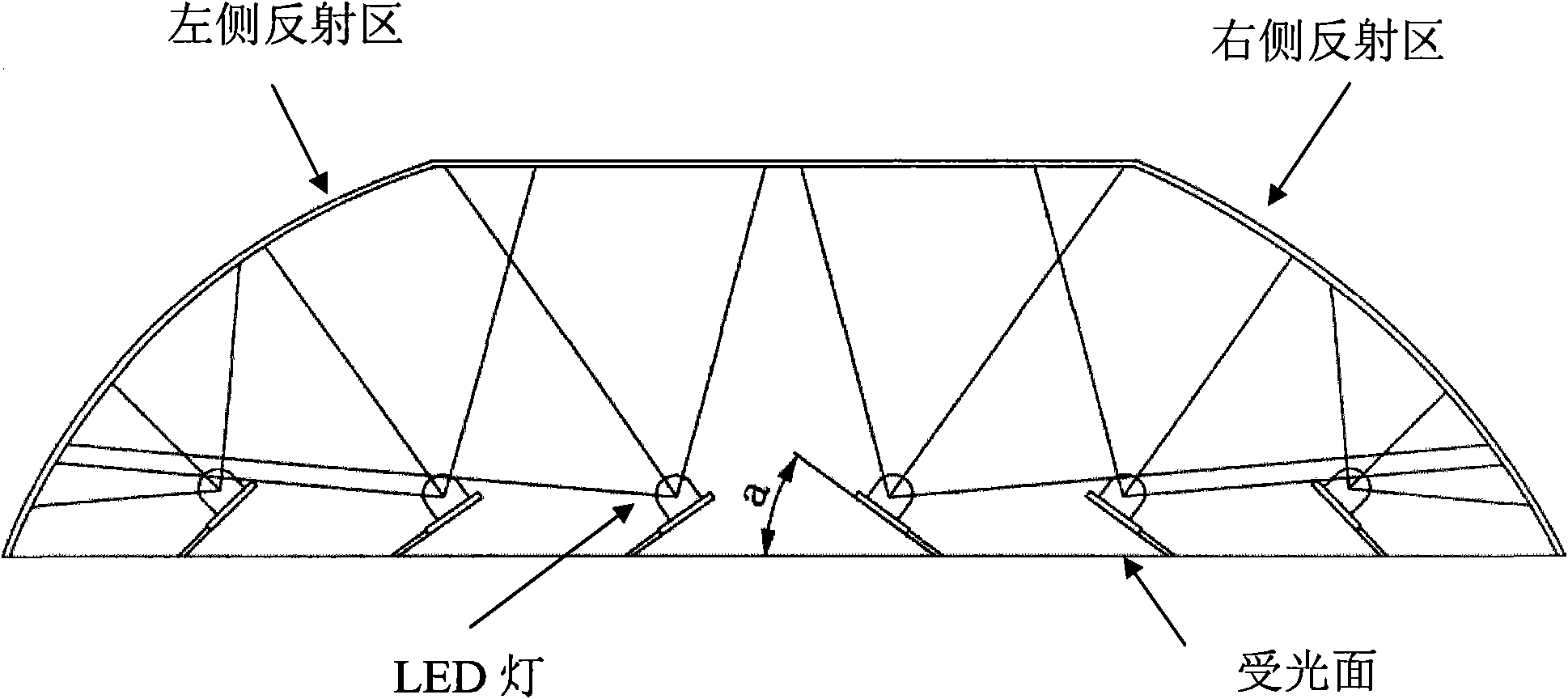

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

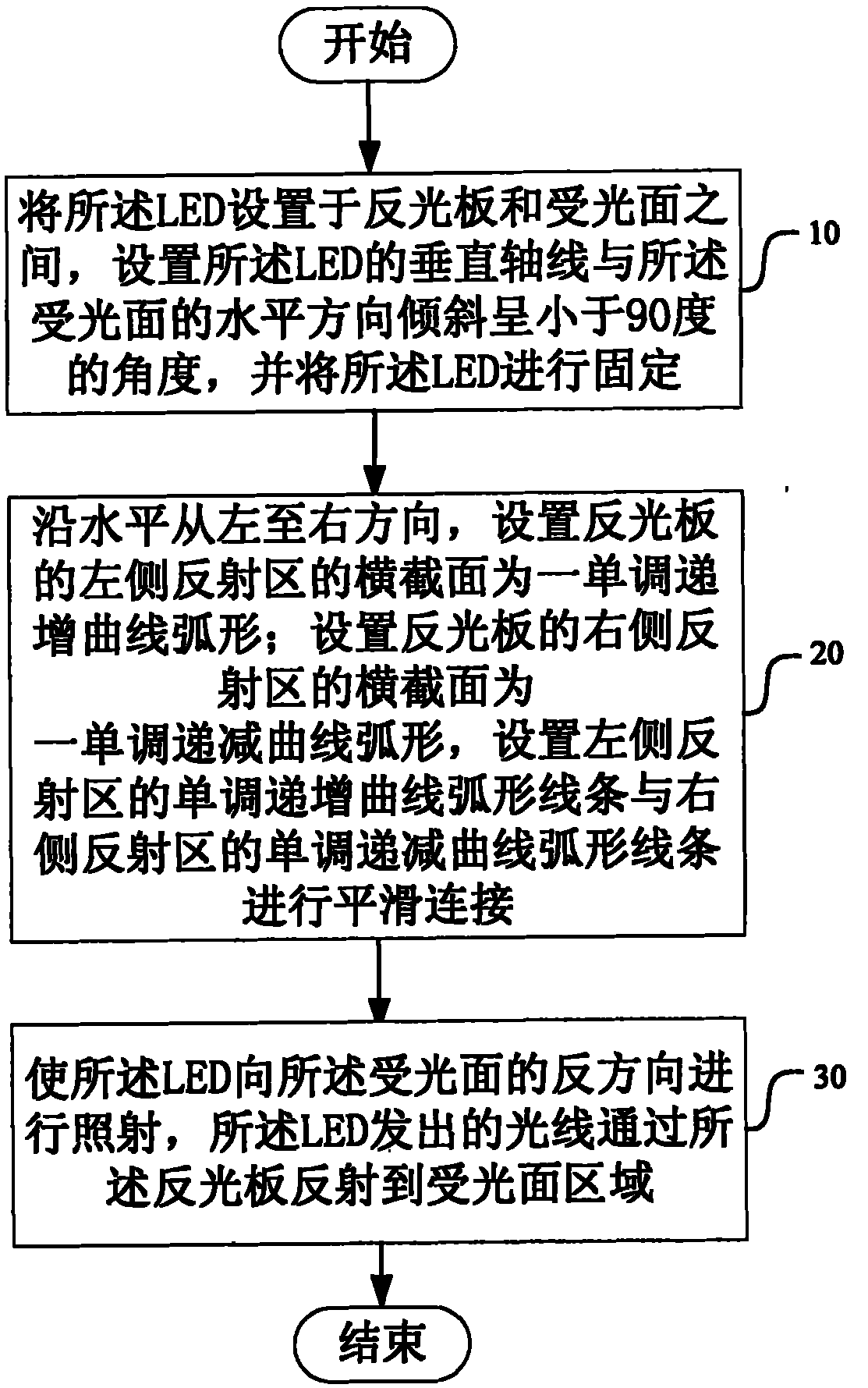

[0023] like figure 1 Shown, the illumination method of a kind of LED of the present invention comprises the following steps:

[0024] Step 10, disposing the LED between the reflector and the light-receiving surface, setting the vertical axis of the LED to be inclined at an angle less than 90 degrees to the horizontal direction of the light-receiving surface, and fixing the LED;

[0025] Said setting said LED between the reflective plate and the light-receiving surface means:

[0026] A plurality of LEDs are arranged between the reflective plate and the light-receiving surface, and the LEDs are arranged horizontally and uniformly.

[0027] The setting that the vertical axis of the LED is inclined at an angle less than 90 degrees to the horizontal direction of the light-receiving surface means:

[0028] Take the midpoint of a straight line for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com