Side light type back light source module

A backlight and side-light technology, which is applied in the field of side-light backlight modules, can solve the problems of low effective utilization of light sources, poor brightness, and inability to be recycled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

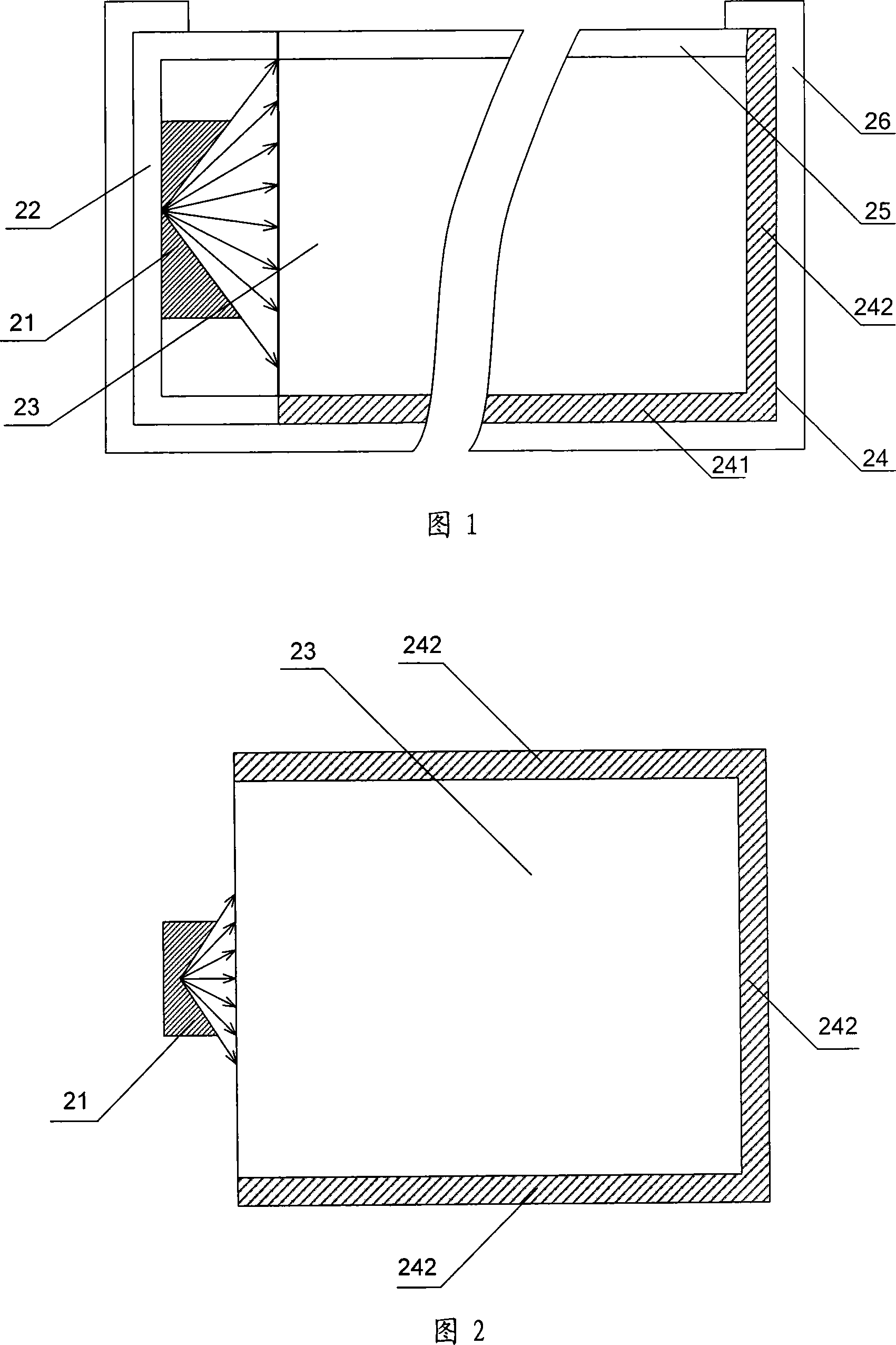

[0025] Fig. 1 is a schematic cross-sectional view of Embodiment 1 of the side-lit backlight module of the present invention. As shown in Fig. 1, the present invention includes a light source 21 for generating light; a light guide plate 23 for reflecting the light generated by the light source 21 and Refraction; the optical module 25 is covered on one side of the light guide plate 23, and is used to receive light from the light guide plate 23 to generate a surface light source; the reflection plate 24 including the bottom reflection plate 241 and the side reflection plate 242 is covered on the said light guide plate 23. The remaining sides of the light guide plate 23 are used to reflect light back into the light guide plate 23 ; the frame 26 is covered outside the reflective plate 24 .

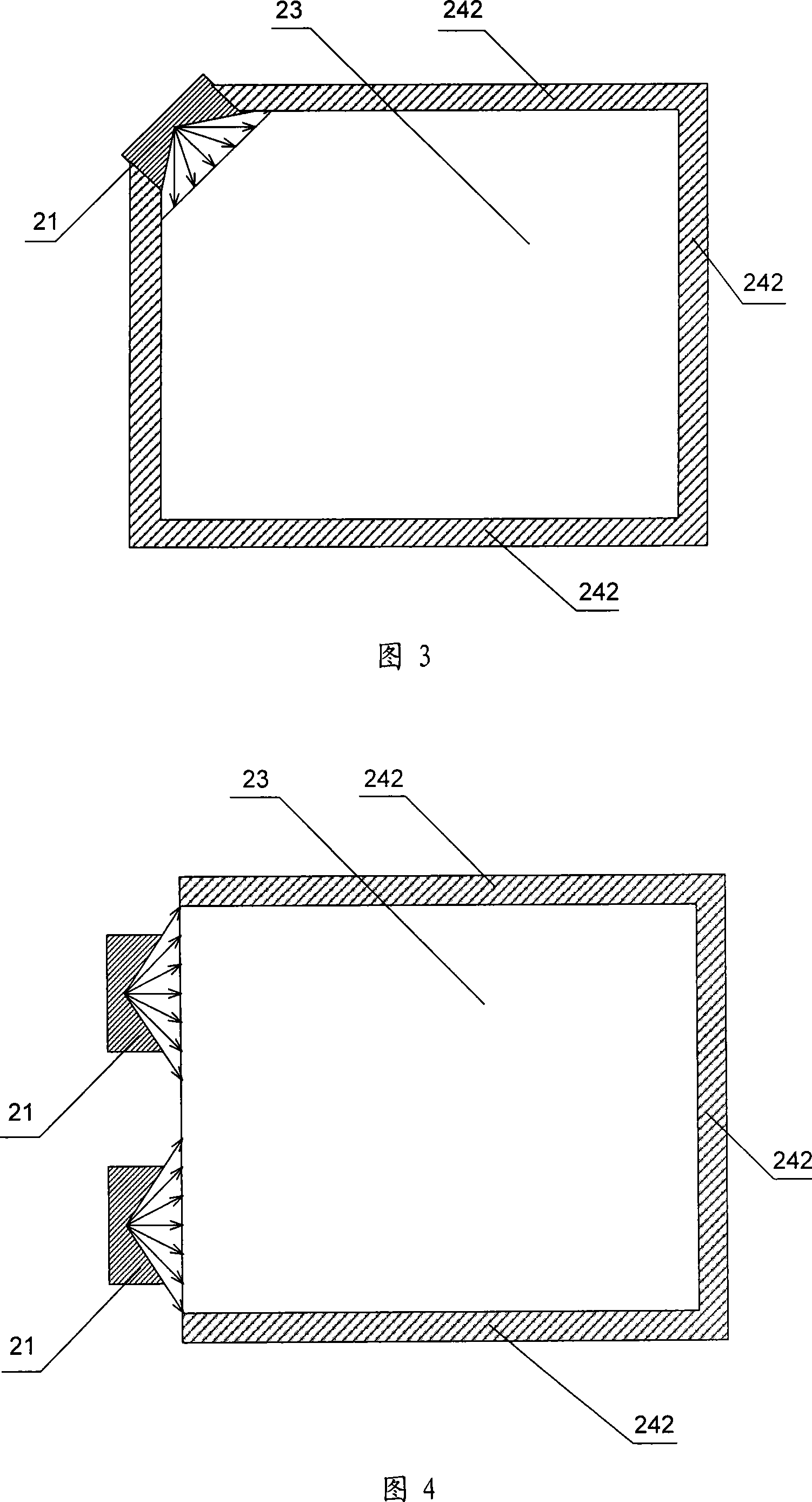

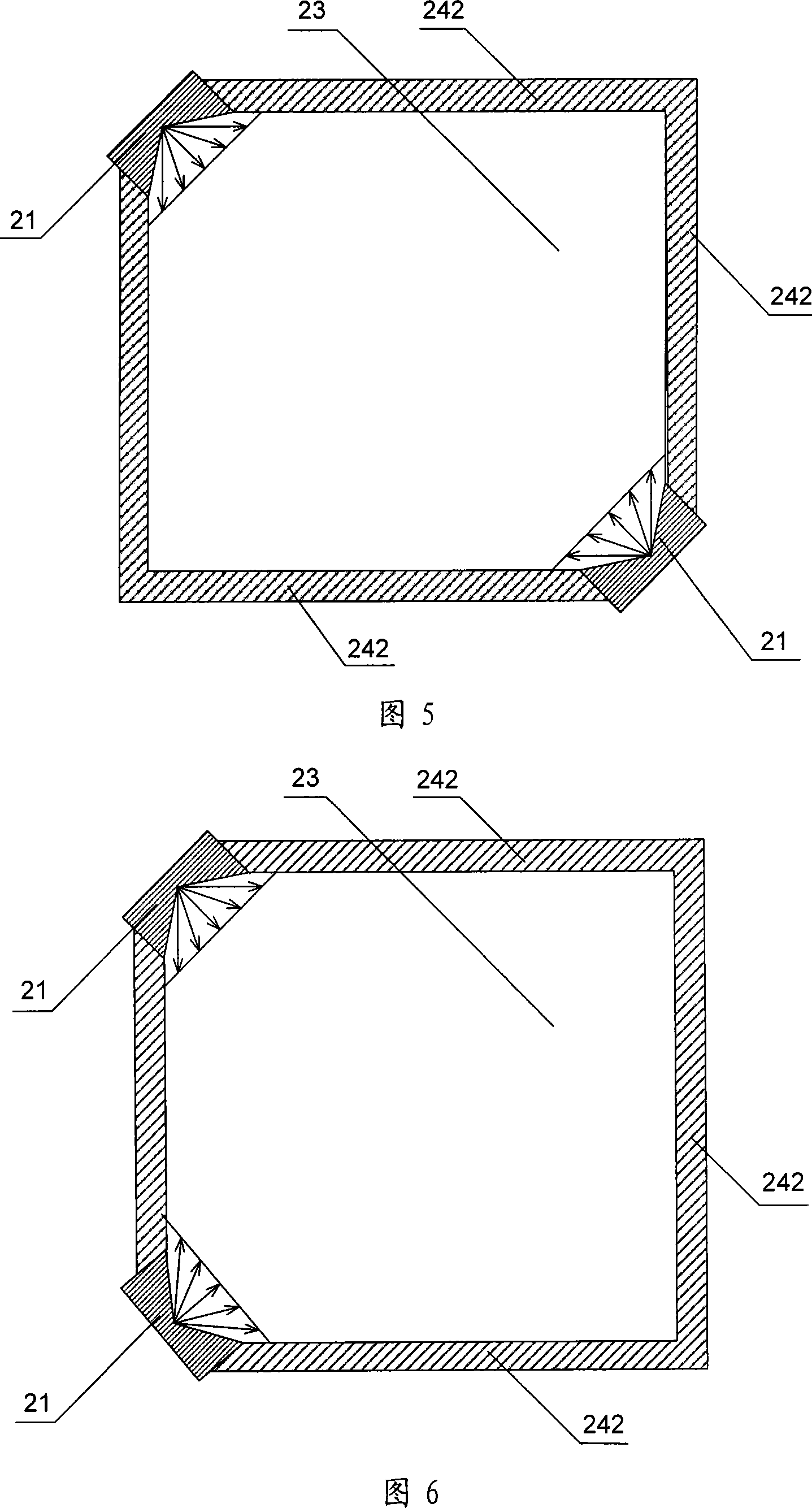

[0026] Specifically, as shown in FIG. 2 , it is a layout diagram of a point light source and a side reflector in this embodiment. The light source 21 is located on one side of the side of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com