Photo-thermal composite catalytic multifunctional reaction system and operation method and application thereof

A reaction system, multifunctional technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes of energy application, energy input, etc., can solve the problems of sudden system shutdown, reduced conversion rate, single function, etc. The effect of controlling the dispersion of the light source and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

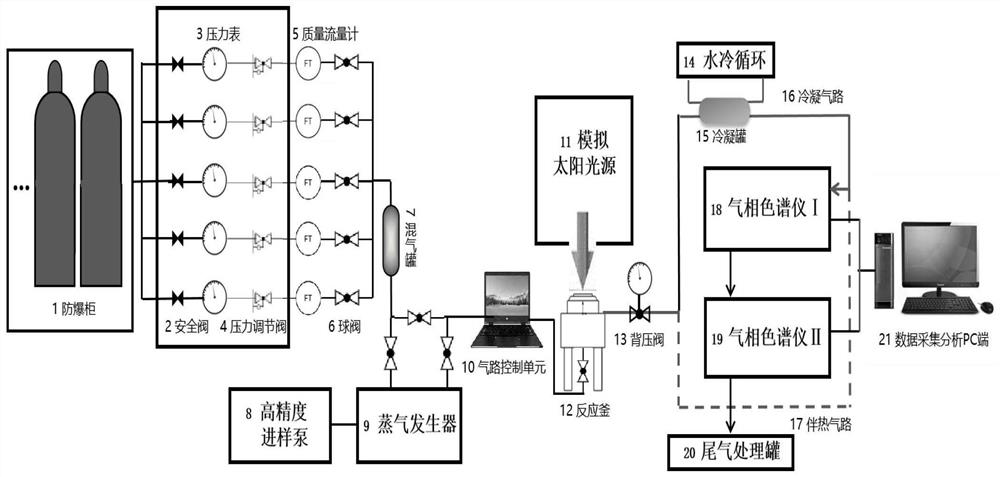

[0025] like figure 1 Described is a photothermal composite catalytic multi-functional reaction system provided by the present invention, including a feeding gas path module (gas cylinder, safety valve, pressure gauge, pressure regulating valve, mass flow meter, ball valve, gas mixing tank, high precision Sampling pump, steam generator), photothermal coupling reaction module (simulated solar light source, reactor), reaction product detection module (back pressure valve, water cooling cycle, condensing tank, condensing gas path, heat tracing pipeline, exhaust gas treatment tank, Gas chromatograph I, gas chromatograph II, data acquisition and analysis PC terminal), system integrated control module (gas circuit control unit, protection control unit); wherein, the reaction kettle chamber is a hollow kettle body structure, and the reaction kettle chamber The bottom is provided with a quartz-made porous catalyst placement platform, the top of the reactor chamber is provided with a qu...

Embodiment 2

[0027] The photothermal composite catalytic multifunctional reaction system provided by the present invention is used in CO 2 The application steps in the hydrogenation to methane reaction are as follows:

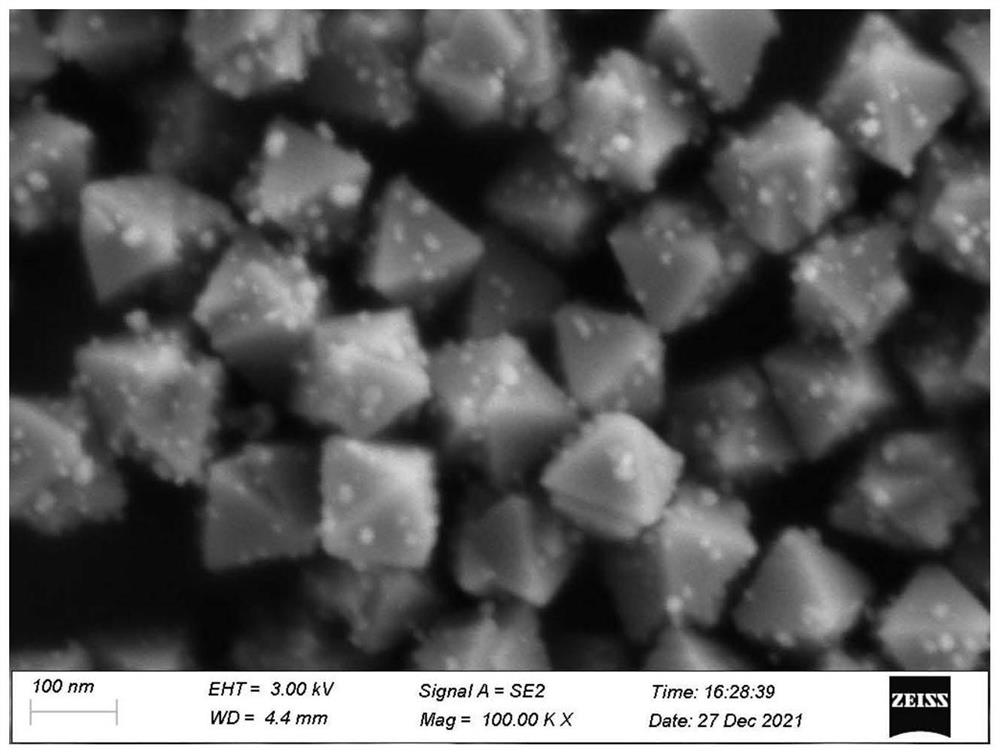

[0028] (1) Before the test, lay a layer of quartz wool on the porous quartz catalytic bed to prevent the catalyst from leaking from the pores. figure 2 The 75mg Ni / CeO 2 The catalyst is evenly spread on the quartz wool;

[0029] (2) Place the light source directly above the reactor. The light source used is a high-uniformity xenon lamp with a total optical power of 50W and a spectral range of 320-800nm. The light intensity on the catalyst surface ranges from 2.43 to 5.25 W / cm 2 .

[0030] Tighten the flange of the reactor, pass Ar from the inlet of the reaction gas, the flow rate is 20ml / min, and detect the actual flow rate of the gas from the gas outlet of the gas chromatograph II (18). If the system is normal, raise the temperature of the reactor to 160°C, switch th...

Embodiment 3

[0035] The application steps of the photothermal composite catalytic multifunctional reaction system provided by the present invention in the dry reforming of methane are as follows:

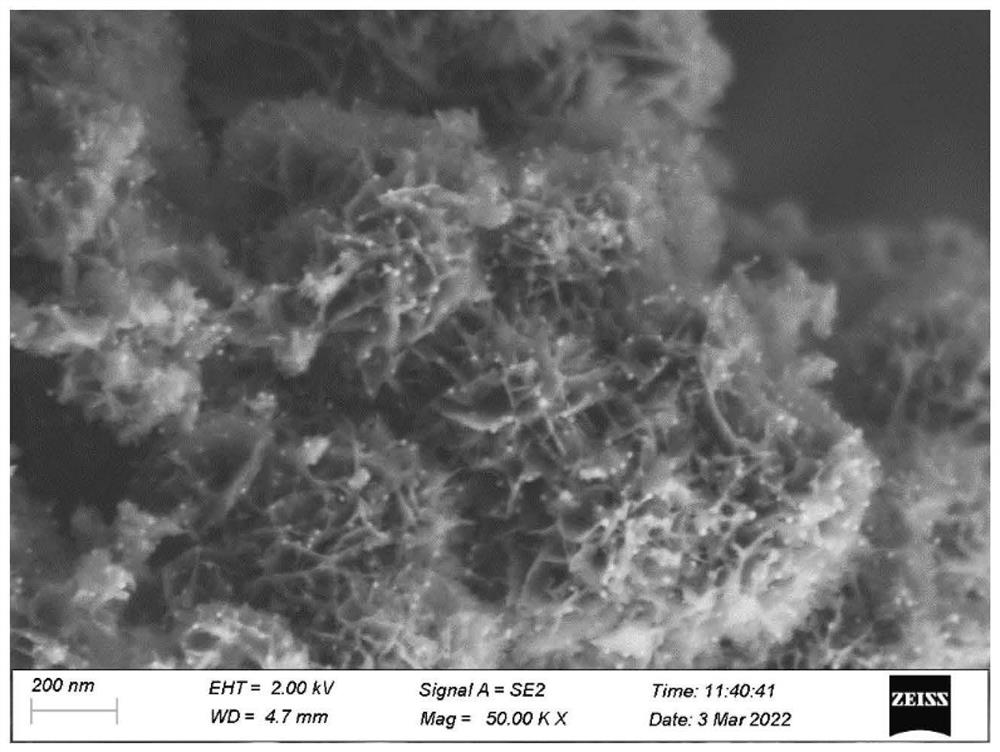

[0036] (1) Before the activity test, use 10% H 2 / N 2 The calcined sample is reduced at high temperature by the mixed gas to expose the active sites of the catalyst. Due to good dispersion, the nano-active metal sites are evenly distributed on the surface of the catalyst, thereby enhancing the light absorption capacity of the catalyst, and a large amount of The active site provides a basis for the improvement of catalytic activity;

[0037] (2) Lay a layer of quartz wool on the porous quartz catalytic bed to prevent the catalyst from leaking out of the pores. image 3 The 5mg NiCo@C / Al 2 O 3 The catalyst is evenly spread on the quartz wool;

[0038] (3) Replace the air in the reactor with Ar, and then switch to CH 4 / CO 2 / Ar(set CH 4 The flow is 12ml / min, CO 2 The mixed gas with the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com