Oxidation catalyst for purifying exhaust gas of diesel engine and preparation method thereof

A technology for oxidation catalysts and diesel engines, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc. It can solve the problems of unfavorable catalyst promotion and application and industrialization, catalyst cost increase, and high loading capacity, so as to prolong the service life, The effect of improving conversion efficiency and increasing storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

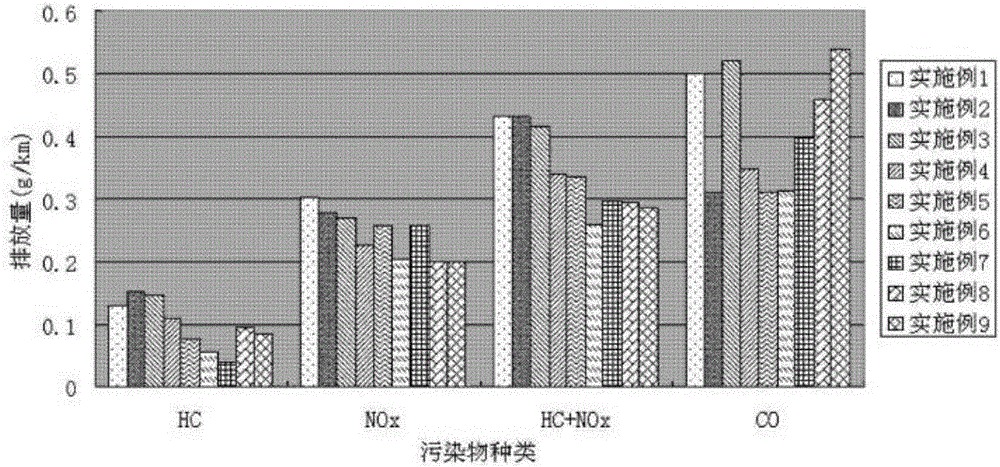

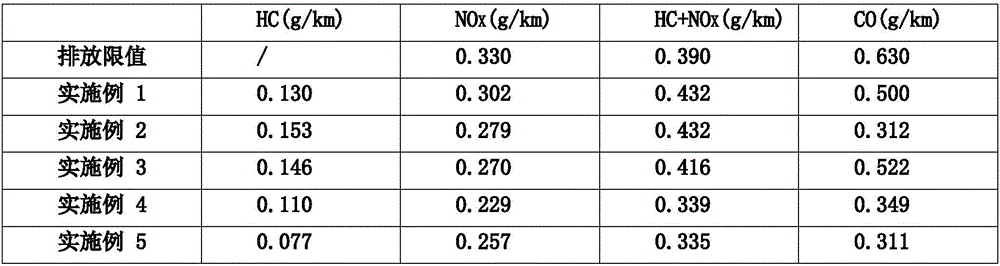

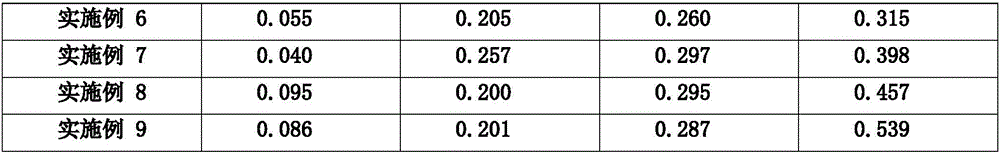

Examples

Embodiment 1

[0026] Mix 12.5 parts by mass of pseudo-boehmite in 375 parts by mass of deionized water, and stir for 15 minutes at a speed of 600r / min; then add 99 parts by mass of activated alumina and 50 parts by mass of Mn-Cr composite Oxide, stir for 30 minutes to mix evenly, adjust the pH of the mixture to 3.5 with acetic acid; transfer the evenly mixed mixture to a ball mill, set the ball mill speed to 1000r / min, grind for 30 minutes, and then move it out to the batching container; Add 40 parts by mass of β molecular sieve to the good mixture, stir for 60 minutes and mix well.

[0027] Calculate according to the mass percentage of precious metal Pt in the catalyst as 0.5% and weigh 13.6 parts by mass of platinum nitrate solution with 10% mass concentration of Pt, and slowly add it to the ground mixture at a speed of 600r / min Stir for 60 minutes to prepare coating liquid.

[0028] Put the cordierite honeycomb ceramic carrier of Ф118.4*152.4mm and 400 / 6.5 on the coating device to coat the c...

Embodiment 2

[0031] Mix 36.25 parts by mass of pseudo-boehmite in 375 parts by mass of deionized water, stir for 15 minutes at a speed of 600r / min; then add 70 parts by mass of activated alumina and 30 parts by mass of Mn-Cr composite Oxide, stir for 30 minutes to mix evenly, adjust the pH of the mixture to 3.5 with acetic acid; transfer the evenly mixed mixture to a ball mill, set the ball mill speed to 1000r / min, grind for 30 minutes, and then move it out to the batching container; Add 70 parts by mass of β molecular sieve to the good mixture, stir for 60 minutes and mix well.

[0032] Calculate according to the mass percentage of precious metal Pt in the catalyst as 0.5% and weigh 13.6 parts by mass of platinum nitrate solution with 10% mass concentration of Pt, and slowly add it to the ground mixture at a speed of 600r / min Stir for 60 minutes to prepare coating liquid.

[0033] Put the cordierite honeycomb ceramic carrier of Ф118.4*152.4mm and 400 / 6.5 on the coating device to coat the coat...

Embodiment 3

[0036] Mix 25 parts by mass of pseudo-boehmite in 375 parts by mass of deionized water and stir for 15 minutes at a speed of 600r / min; then add 99 parts by mass of activated alumina and 40 parts by mass of Mn-Cr composite oxide to it, Stir for another 30 minutes to mix evenly, adjust the pH of the mixture to 3.5 with acetic acid; transfer the evenly mixed mixture to a ball mill, set the speed of the ball mill to 1000r / min, grind for 30 minutes, and move it out to the batching container; Add 40 parts by mass of β molecular sieve to the solution, stir for 60 minutes and mix well.

[0037] Calculate according to the mass percentage of precious metal Pt in the catalyst as 0.5% and weigh 13.6 parts by mass of platinum nitrate solution with 10% mass concentration of Pt, and slowly add it to the ground mixture at a speed of 600r / min Stir for 60 minutes to prepare coating liquid.

[0038] Put the cordierite honeycomb ceramic carrier of Ф118.4*152.4mm and 400 / 6.5 on the coating device to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com