Measuring method for bonding strength of tobacco leaves

A measurement method and technology of tobacco leaves, applied in the direction of measuring devices, instruments, mechanical devices, etc., to achieve the effect of accurate data support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

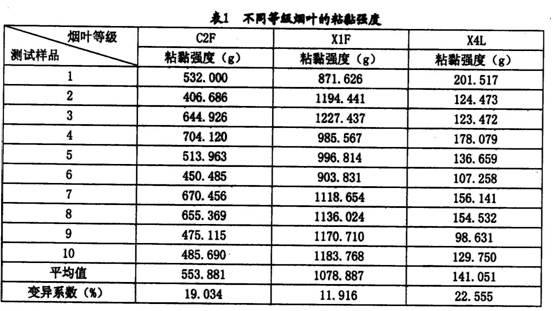

Image

Examples

Embodiment Construction

[0022] The present invention is further described below in conjunction with embodiment:

[0023] Select the texture analyzer and meet the following equipment conditions: the pressure surface of the pressure probe is smooth; the pressure probe should be fixed and the contact surface with the pressure probe should be smooth.

[0024] The specific test method is as follows:

[0025] ① Selection of tobacco leaf samples for determination

[0026] Tobacco leaf samples with complete leaves, no obvious dust on the leaf surface and no spots were selected as the test samples in the test samples.

[0027] ②Test the moisture balance of tobacco leaf samples

[0028] Put the selected tobacco leaf samples into the temperature: (20±1) ℃, humidity: (75±5)% constant temperature and humidity environment conditions to balance for 48h.

[0029] ③Sample preparation

[0030] First cut off the leaf tip and leaf end of the moisture-balanced tobacco leaf sample, and keep the 10 cm long middle part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com