Screw propulsion mechanism of high-voltage AC vacuum circuit breaker

A vacuum circuit breaker, high-voltage AC technology, applied in switchgear, pull-out switchgear, electrical components, etc., can solve the problem of inability to easily and conveniently realize the operation of entering and exiting the vehicle, large insertion and withdrawal force of dynamic and static contacts, and force when pushing Large and other problems, to achieve the effect of increasing the rigidity and stability of the lock, improving the stress condition, and reducing the rotational force of the handlebar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

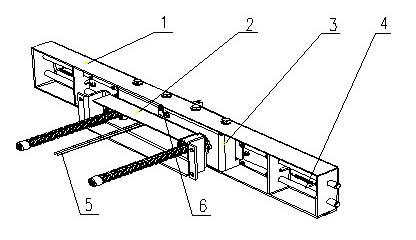

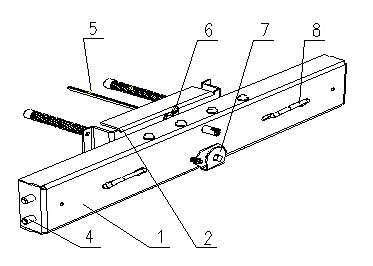

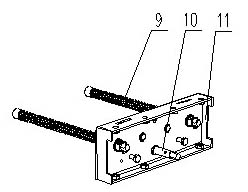

[0011] like Figure 1 to Figure 4 As shown, two lead screws 9 are inserted into the propulsion plate 2 of the lead screw propulsion mechanism of the high-voltage AC vacuum circuit breaker, and the two lead screws 9 and the operating rod 10 are inserted into the gearbox 11 to form a double lead screw gearbox assembly 3 , the end of the lead screw 9 inserted into the gearbox 11 is installed with a large gear 12, the end of the operating rod 10 inserted into the gearbox 11 is installed with a pinion 13, and its end is connected with the locking push plate 7, the said The two large gears 12 and the pinion 13 mesh with each other, the double-screw gearbox assembly 3 is installed in the middle position inside the front assembly frame 1, the interlocking rod 5 penetrates through the front assembly frame 1 and the interlocking rod 5 There is an interlocking arm 6 on it. The inner two ends of the front assembly frame 1 are respectively equipped with two locking bolts 4 for locking the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com