Method for processing tobacco pulp

A processing method and technology for tobacco pulp, which are applied in directions such as tobacco, tobacco preparation, application, etc., can solve the problems of high content of miscellaneous cells in tobacco pulp, adverse effects on papermaking, etc. The effect of copying the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

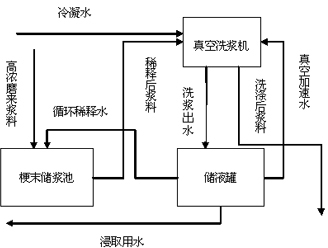

[0023] After the raw materials are leached in water, they are squeezed into a dryer for solid-liquid separation. The extruded leaching liquid is concentrated and evaporated, and the condensed water obtained from the concentrated evaporation enters the vacuum pulp washing system as water for pulp washing; The final pulp storage tank, the pulp in the stem end pulp storage tank is diluted to a solid content of 1.8% and then enters the vacuum pulp washing system. After pulp washing, the pulp is dehydrated and concentrated to a pulp water content of 8% before further beating and papermaking ; while the effluent from the pulp washing system can be diluted and leached separately and used to speed up the pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com