Tube external circle repairing device

A technology for pipes and pipe fittings, which is applied in the field of pipe outer circle repairers, can solve the problems that cannot meet the requirements of pipe outer circle accuracy and wall thickness accuracy, restrict pipe reliability and consistency, and cannot meet product progress, etc. Reduced strength, increased relative linear motion distance, and small vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

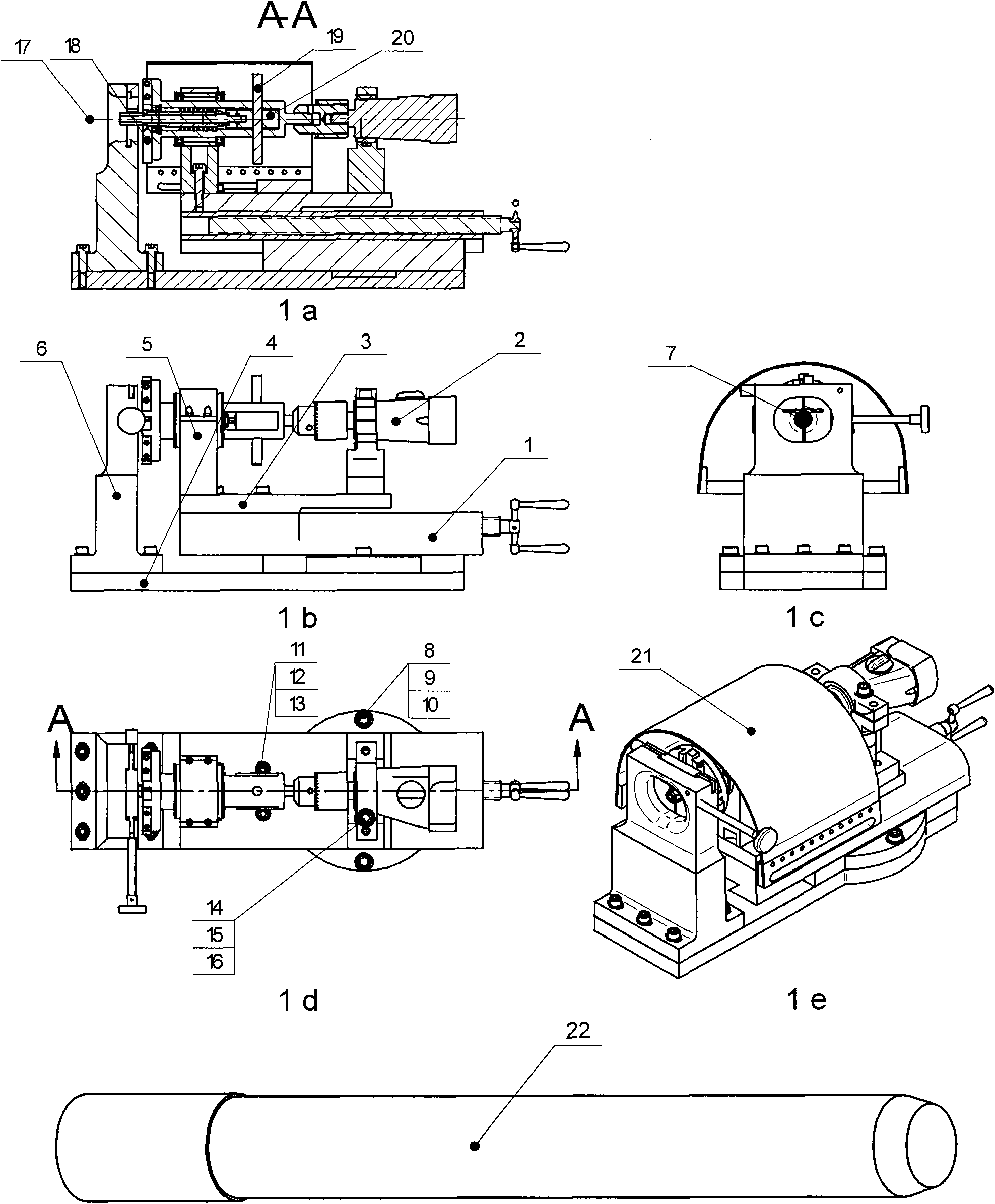

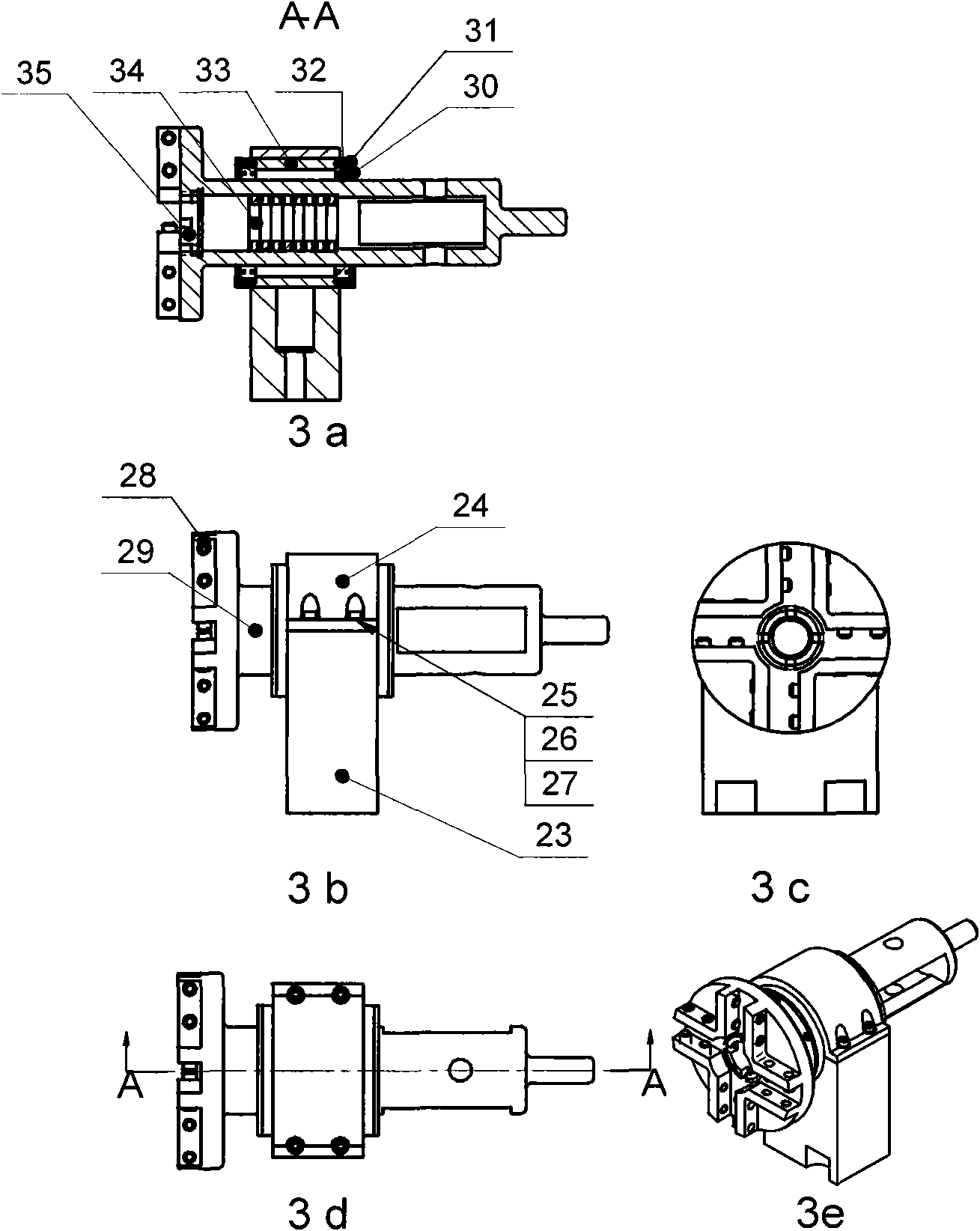

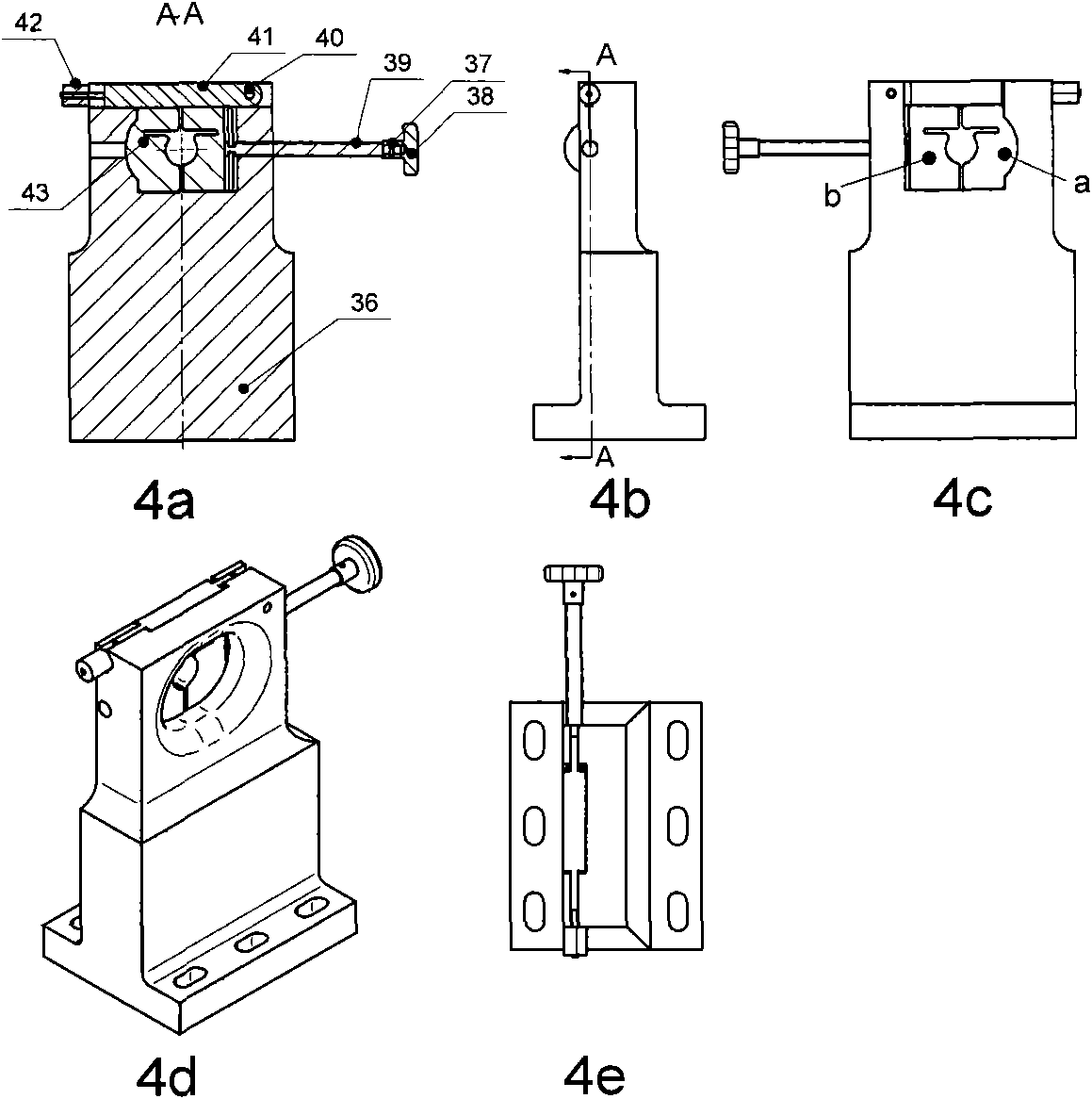

[0034] As shown in Figures 1, 2, 3, 4, 5, and 6, the pipe outer circle trimmer of the present invention includes a small supporting plate 1, a power mechanism 2, a small bottom plate 3, a large bottom plate 4, a tool holder 5, and a pipe fitting holder 6. Mandrel 7, M10 hexagon socket head screw 8, Φ10 flat washer 9, Φ10 spring washer 10, M8 hexagon socket head screw 11 (14), Φ8 flat washer 12 (15), Φ8 spring washer 13 (16) , tool 18, tightening block 20, booster rod 19, protective cover 21, knife setting bar 22; tool holder 5 includes tool holder mounting base 23, tool holder mounting base upper cover 24, M3 socket head cap screw 25, Φ3 flat Washer 26, Φ3 spring washer 27, M6 inner hexagon flat end set screw 28, main shaft 29, bearing cover 30, M2 cross recessed countersunk head screw 31, 100808 single row radial ball bearing 32, bearing sleeve 33, 1000803 single row radial ball Bearing 34, swarf nut 35; pipe fitting holder 6 includes pipe fitting holder mounting base 36, fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com