Automatic discharging device for flame cutting tail gas

An automatic emission and flame cutting technology, which is applied in gas flame welding equipment, welding equipment, metal processing equipment, etc., to solve the problem of exhaust emission, improve the quality of cutting workpieces, and avoid redundant cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

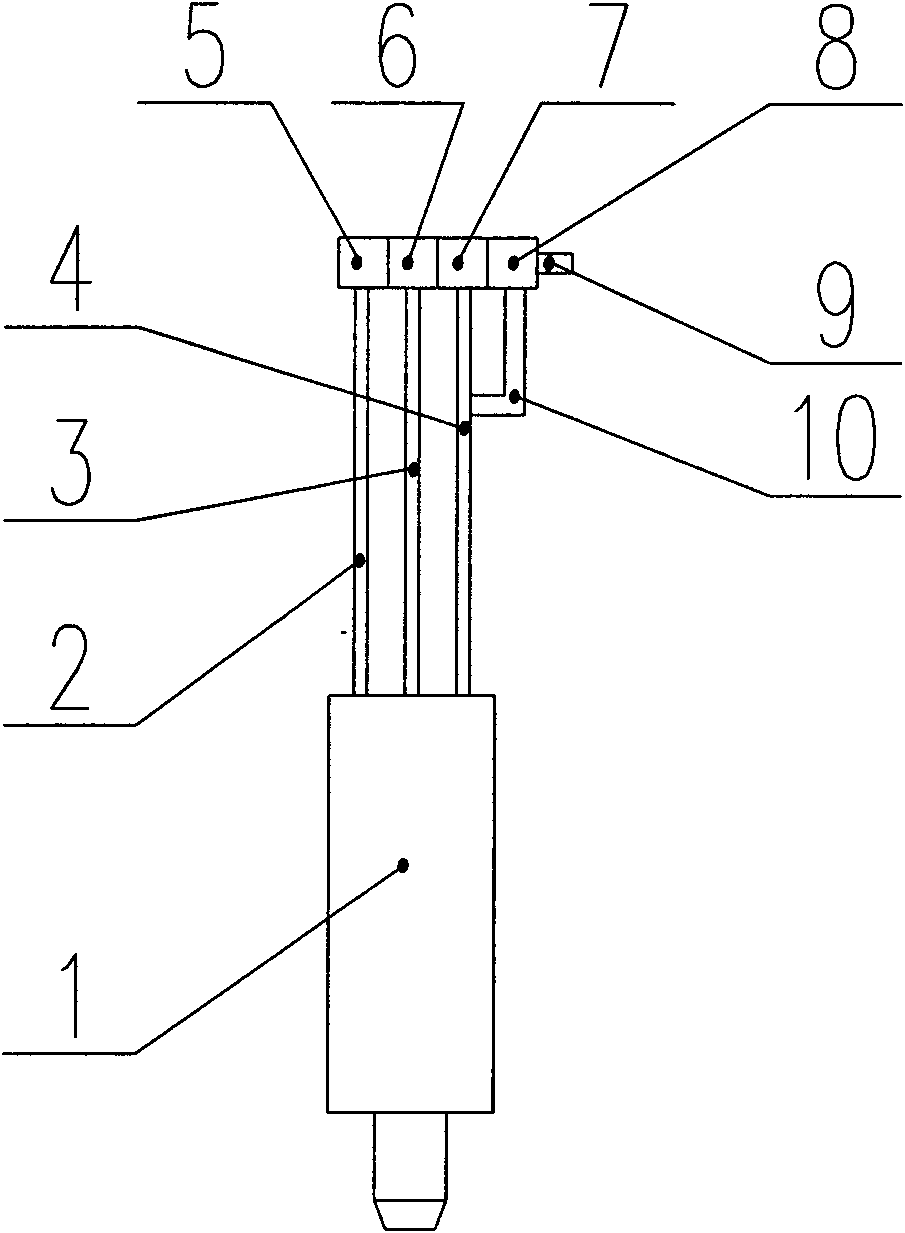

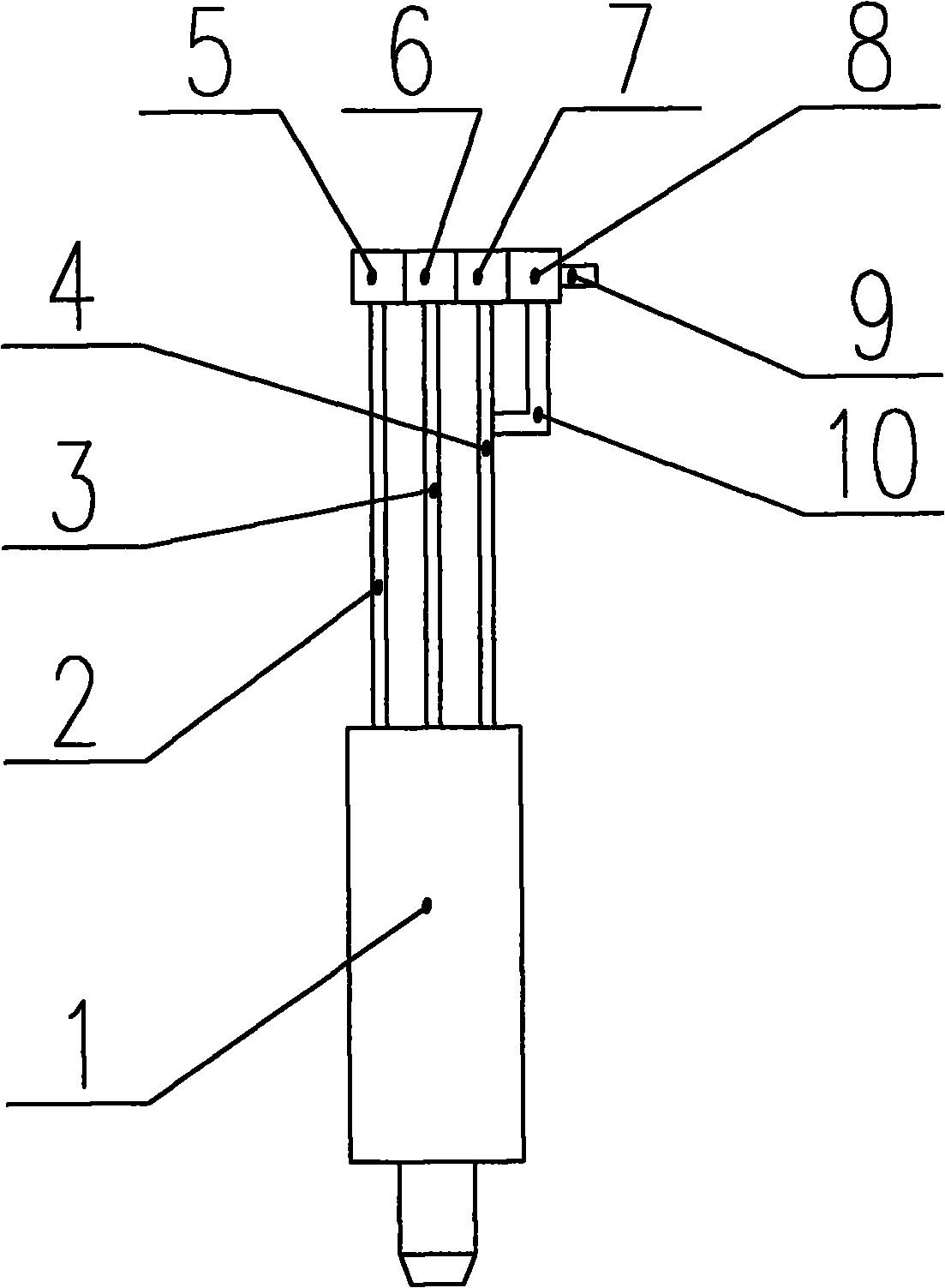

[0010] Such as figure 1 As shown, the present invention mainly consists of cutting torch 1, gas pipe 2, preheating oxygen pipe 3, cutting oxygen pipe 4, gas pipe solenoid valve 5, preheating oxygen pipe solenoid valve 6, cutting oxygen pipe solenoid valve 7, and exhaust gas discharge electromagnetic valve. Valve 8, muffler 9 and exhaust pipe 10 are composed. Gas pipe 2, preheating oxygen pipe 3 and cutting oxygen pipe 4 are all connected to cutting torch 1 respectively; On hot oxygen pipe 3, cutting oxygen pipe 4. Tail gas discharge pipe 10 communicates with cutting oxygen pipe 4 inner chambers, tail gas discharge electromagnetic valve 8 is installed on tail gas discharge pipe 10, and muffler 9 is installed on the exhaust port of tail gas discharge solenoid valve 8 to eliminate the abnormal sound when exhaust gas is discharged. In order to make th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap