Method for processing small nozzle

A processing method and nozzle technology, applied in the processing field of nozzles, can solve the problems such as the thread and the workpiece are not concentric, the drill bit is small, and it is easy to cause a gap, so as to improve the consistency of clamping, ensure the quality of the thread, and increase the fitting area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

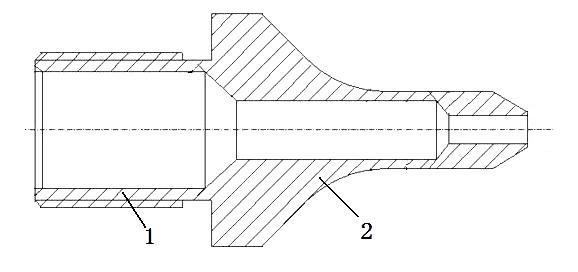

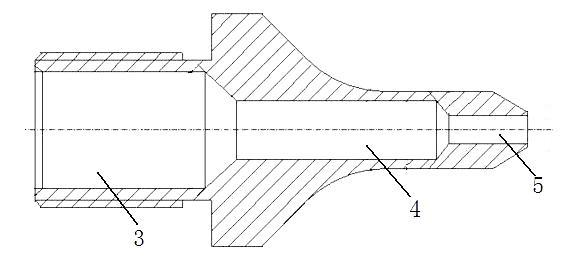

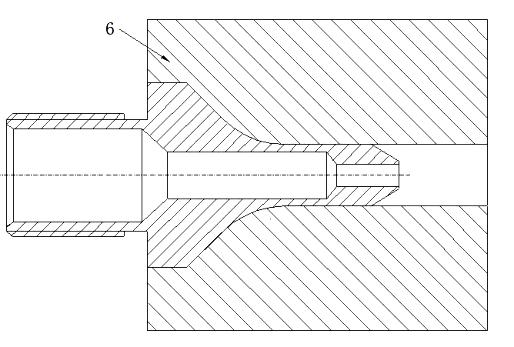

[0033] As an embodiment of the present invention, on the second nozzle segment 2, from the end adjacent to the first nozzle segment 1, there are two diameter-reducing segments in sequence, one of which is the largest outer diameter segment from the position adjacent to the first nozzle segment 1. The outer diameter of the segment is reduced after rounding with a radius of 1mm, and the reduced outer diameter is slightly larger than the inner diameter of the second guide hole 4, where the inner diameter of the second guide hole 4 is 0.9mm, and the inner diameter of the third guide hole 5 The diameter is 0.35mm, the end of the third guide hole 5 away from the first nozzle section 1 is a thin wall with an outer diameter of 0.45mm, and the end of the third guide hole 5 near the first nozzle section 1 has an outer diameter greater than 0.45mm, After beveling, the reduced diameter is 0.45mm. The outer circle of the first nozzle section 1 is a threaded section with an outer diameter o...

Embodiment 2

[0046] As the second embodiment of the present invention, on the second nozzle section 2, from the end adjacent to the first nozzle section 1, there are two diameter-reducing sections in sequence, one of which is from the largest outer section located close to the first nozzle section 1. The outer diameter of the diameter section is reduced after being rounded with a radius of 1mm, and the reduced outer diameter is slightly larger than the inner diameter of the second guide hole 4, where the inner diameter of the second guide hole 4 is 0.9mm, and the inner diameter of the third guide hole 5 The diameter of the hole is 0.35mm, the end of the third guide hole 5 away from the first nozzle section 1 is a thin wall with an outer diameter of 0.45mm, the outer diameter of the end of the third guide hole 5 close to the first nozzle section 1 is greater than 0.45mm, and passes through a After chamfering, the diameter is reduced to 0.45mm. The outer circle of the first nozzle section 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com