Numerical control processing method of elastic bracket

The technology of an elastic support and a processing method is applied in the field of numerical control machining of elastic supports, which can solve the problems of high processing stress, difficult to ensure the wall thickness requirements at corners, long processing cycle, etc., and achieve the effect of dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

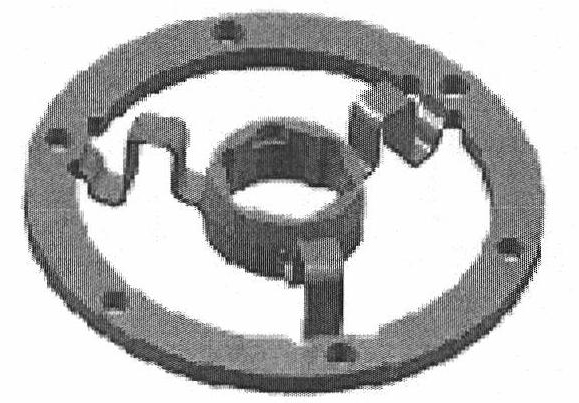

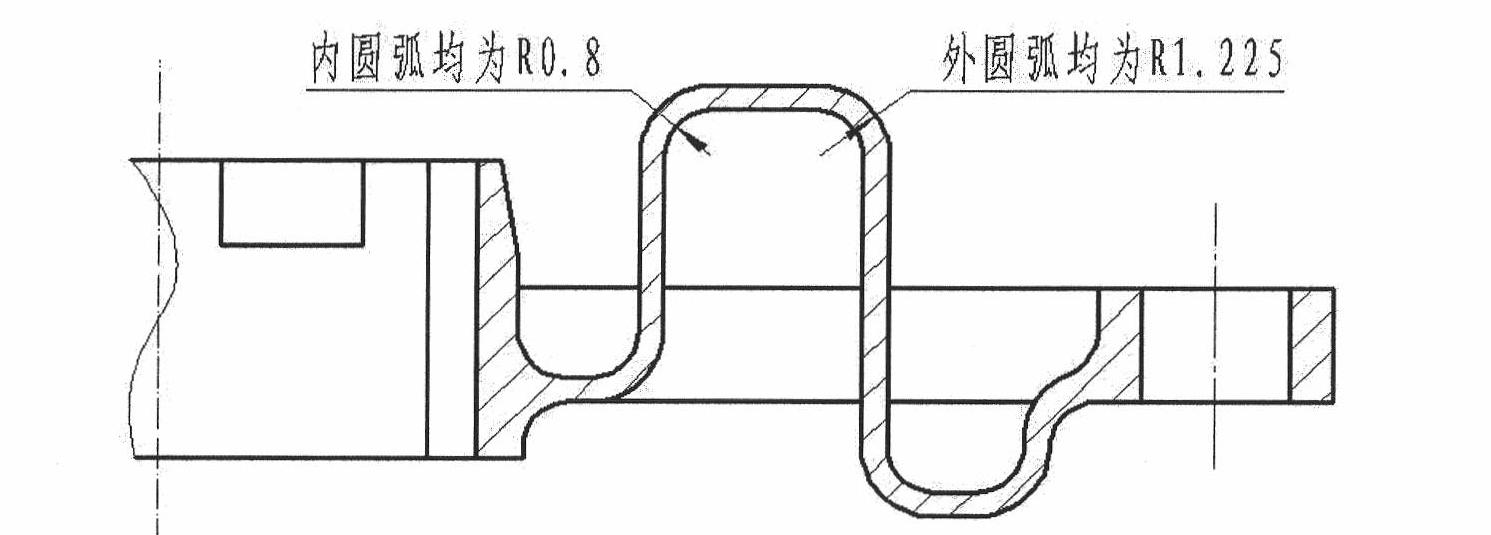

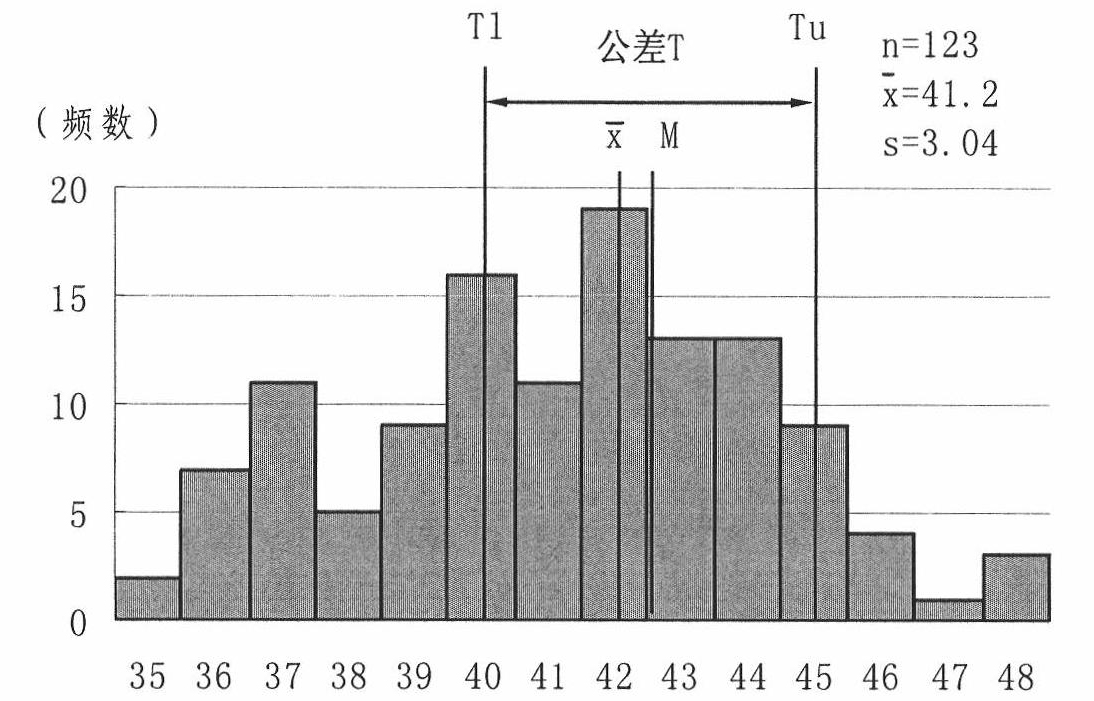

[0046] The following describes this aspect in detail in conjunction with specific examples, such as figure 1 As shown, the elastic support to be processed is an elastic part of hard aluminum alloy. The specific structure is a Φ40 ring with a thickness of 2mm connecting three evenly distributed special-shaped spring pieces with a thickness of 0.425mm. The special-shaped spring pieces have the following characteristics: figure 2 The multiple inner arcs and outer arcs shown; the hollow shaft with a length of 7mm in the center, and the upper half of the hollow shaft is a 15-degree conical surface; firstly, analyze the difficulties:

[0047] 1) The shape of the elastic bracket is complex, the thickness of the spring piece is thin, it is easy to deform, the tolerance requirements of key dimensions are strict, and the size control is difficult.

[0048] 2) The inner and outer arcs need to be rounded with non-standard forming milling cutters, and a smooth transition between the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com