Crankshaft automatic indexing holddown device

A technology of automatic indexing and pressing device, which is used in metal processing mechanical parts, drilling dies for workpieces, precision positioning equipment, etc. The effect of high pressing action efficiency and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

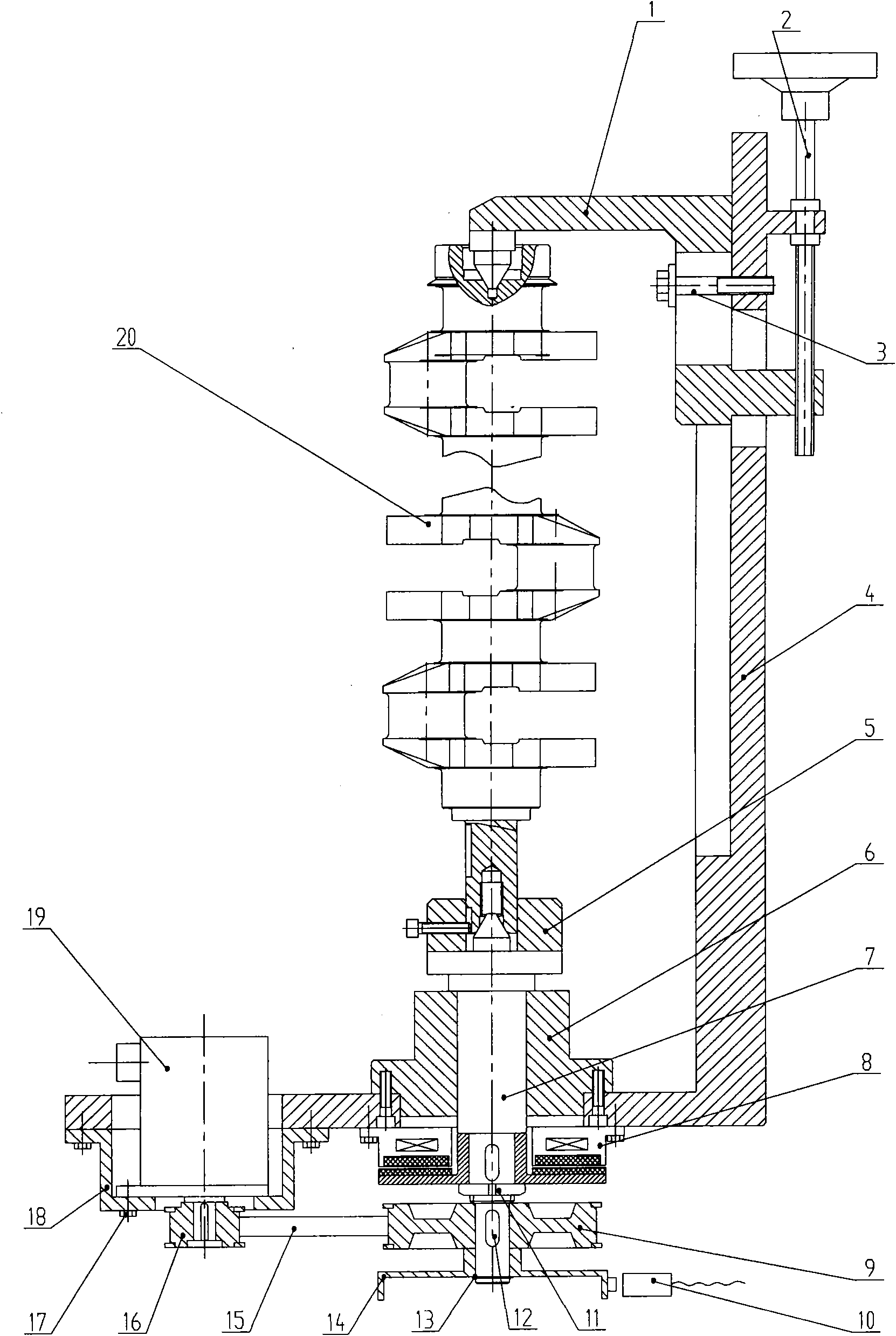

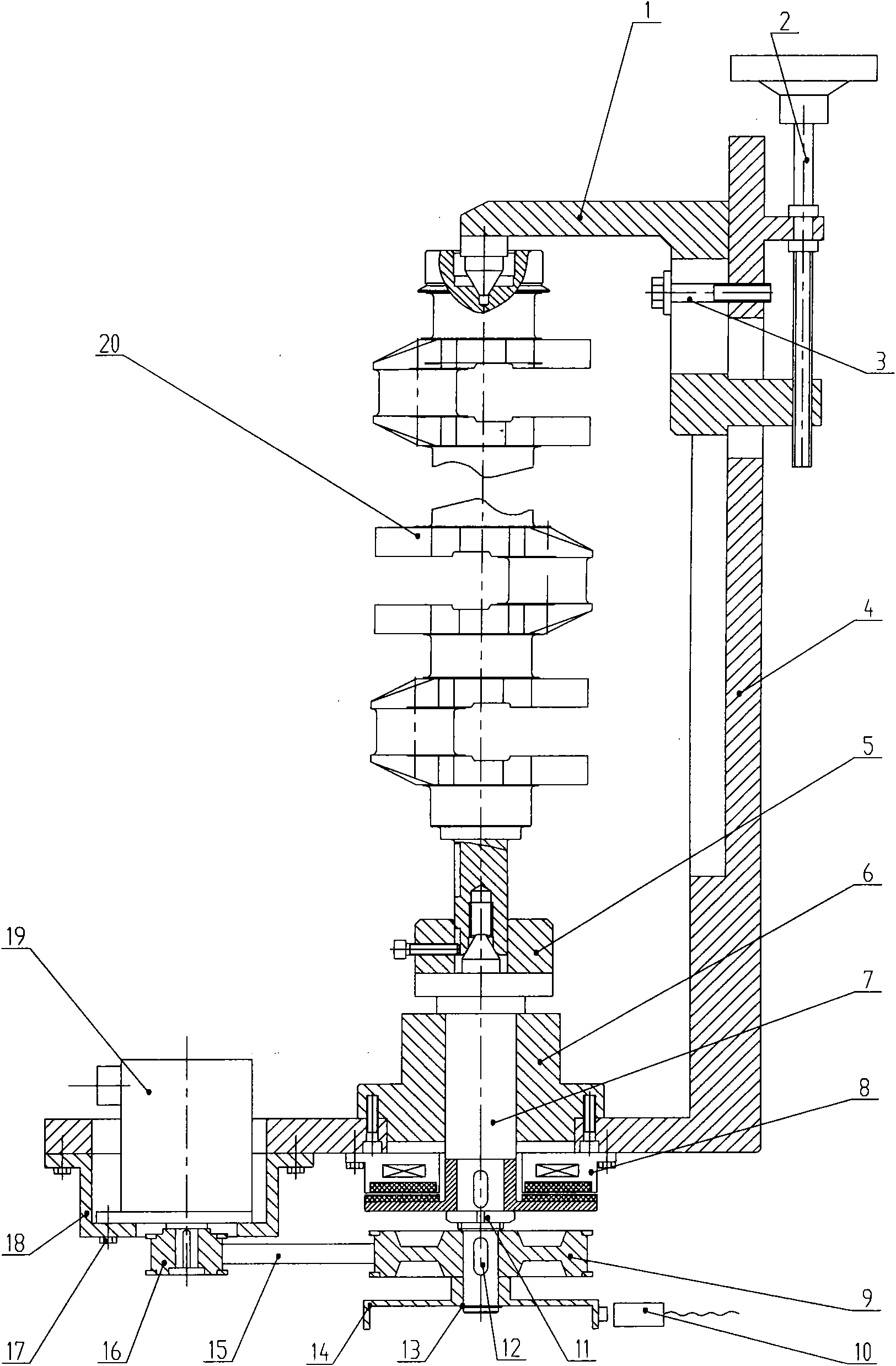

[0012] From figure 1 It can be seen from the figure that a crankshaft automatic indexing and pressing device includes an upper pressing block 1, a lead screw 2, a locking bolt 3, a bracket 4, a chuck 5, a rotating shaft seat 6, an indexing rotating shaft 7, and an electromagnetic brake 8. Indexing motor 19, etc.

[0013] Described support 4 is " L " right-angled shape, and its one right-angled side is provided with slideway, and rotating shaft seat 6 installation holes and indexing motor 19 installation holes are arranged on the other right-angled side. Upper pressing block 1 is installed on the slideway of support 4, can slide up and down. The indexing rotating shaft 7 is installed in the rotating shaft seat 6, and the indexing motor 19 is installed on the motor mount 18 fixed on the support 4 by bolts 17. Specifically, there is a flat plate on the back side of the slideway for supporting the screw 2, and one end of the upper pressing block 1 is provided with a tip downward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com