Impact-resistant composite packaging buffer material

A composite packaging and buffer material technology, applied in the field of packaging materials, can solve the problems of environmental white pollution and non-degradation, and achieve the effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

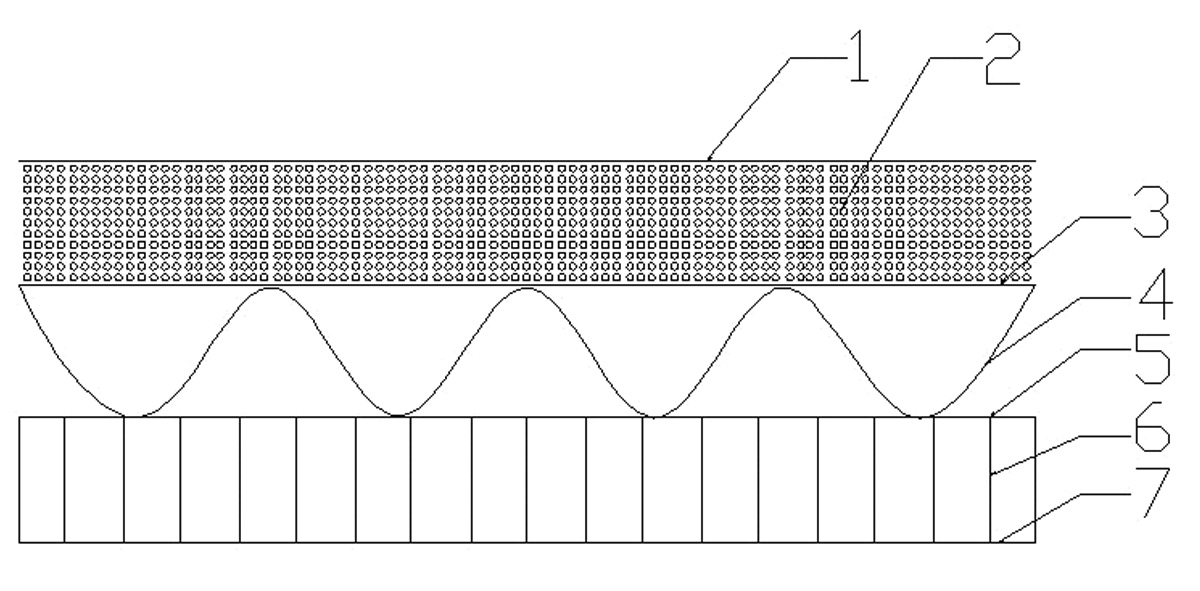

[0021] refer to figure 1 , the present embodiment comprises outer surface paper 1, bottom surface paper 7, sandwich paper I3, sandwich paper II5, corrugated paper core 4, honeycomb paper core 6, and a wood-plastic foam material layer 2 is also provided, and the outer layer paper Between 1 and sandwich paper I3 is wood-plastic foam material layer 2, between sandwich paper I3 and sandwich paper II5 is corrugated paper core 4, and between bottom surface paper 7 and sandwich paper II5 is honeycomb paper core 6; The wood-plastic foam material layer 2, the corrugated paper core 4 and the honeycomb paper core 6 have the same height.

[0022] The wood-plastic foam material is PE, PP, PVC or PS wood-plastic foam material, the cell structure is closed cell, and the pore diameter is 0.5~5mm.

[0023] The shape of the corrugated paper core 4 is V, U or UV flute, and the interface structure of the corrugated paper core 4 is A, B, C, E, F, G, N or O flute, which conforms to the GB / T 6544-2...

Embodiment 2

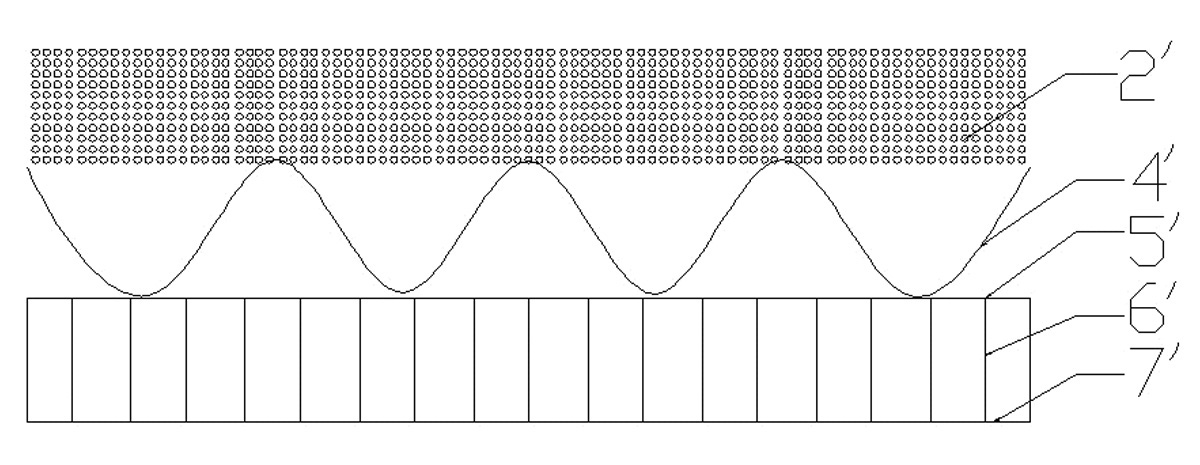

[0028] refer to figure 2 , this embodiment includes the bottom face paper 7', sandwich paper 5', corrugated paper core 4', honeycomb paper core 6', also has wood-plastic foam material layer 2', wood-plastic foam material layer 2' and clip Between the core paper 5' is a corrugated paper core 4', between the bottom surface paper 7' and the sandwich paper 5' is a honeycomb paper core 6'; wood-plastic foam material layer 2', corrugated paper core 4' and honeycomb paper core 6 'The height is the same.

[0029] Compared with the product of Example 1, the product of this embodiment has one layer of paper and one layer of sandwich paper, which has a great price advantage.

Embodiment 3

[0031] The difference between this embodiment and embodiment 2 is that there is no bottom surface paper 7' and sandwich paper 5', the wood-plastic foam material layer 2' is directly bonded to the corrugated top of the corrugated paper core 4', and the corrugated paper core 4' is directly bonded. The corrugated roof is directly bonded to the honeycomb paper core 6'; the wood-plastic foam material layer 2', the corrugated paper core 4' and the honeycomb paper core 6' have the same height.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com