Tobacco shred storage and supply device and process

A shredded tobacco and feeding technology, which is applied in the field of wire feeding machine, can solve the problems of low effective utilization rate of the storage capacity of the storage cabinet, difficulty in controlling the precision of filling shredded tobacco, and inability to realize the docking of the shredded wire feeding machine, so as to save the number of AGVs, Good layout, reduce the effect of occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

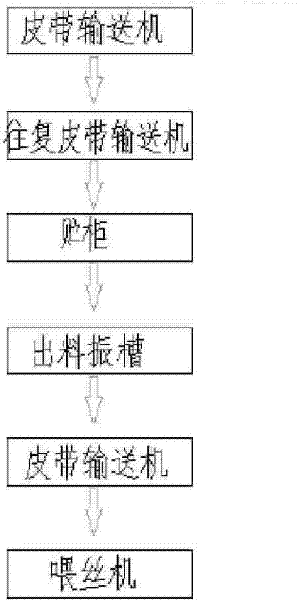

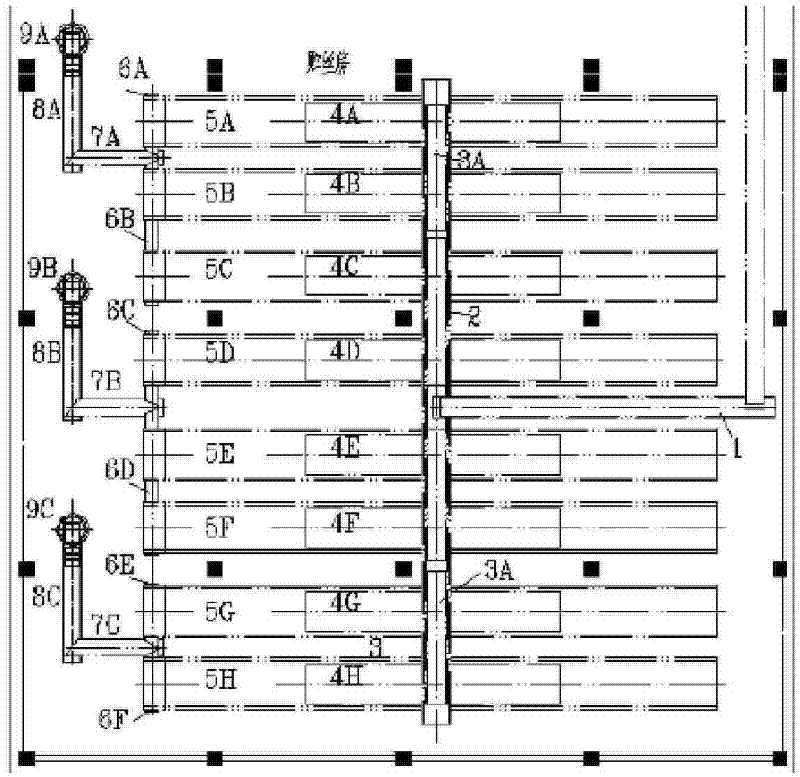

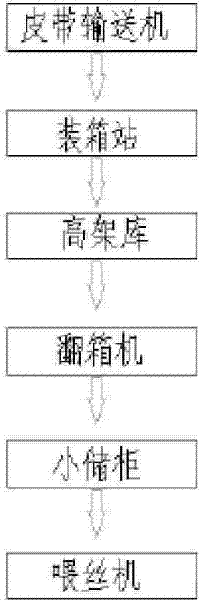

[0050] Please check figure 1 and figure 2 , a shredded tobacco storage and supply device, which is connected between the wire making machine and the wire feeding machine, which includes a belt conveyor 1, a single box multi-station cycle packing station 3, a drive-in shelf 6, Two mobile robot case turning machines 8, eight small storage cabinets 9, a full case output station 4, a full case supply station 7, multiple conveying mechanisms 5, an empty case feed station 2, three shredded tobacco extraction funnels 10 and an empty case Box output station 11.

[0051] The single case multi-station cycle packing station 3 includes a cloth conveyor that reciprocates left and right and two symmetrically arranged charging heads. The cloth conveyor receives the shredded tobacco produced by the thread making machine through the belt conveyor 1 . Each charging head includes a lid handler, a stainless steel sleeve, a weighing bridge, a compactor and a load cell. The weighing bridge is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com