Internal transmission furnace bottom assembly with large gear ring

A large ring gear and furnace bottom technology, which is applied in the field of transmission furnace bottom assembly in the large ring gear, can solve the problems of affecting the normal rotation of the ash tray 1, affecting the normal operation of production, laborious and other problems, so as to avoid disassembly and maintenance of the furnace bottom assembly The operation is simple, the structure is simple, and the effect of normal and continuous operation is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

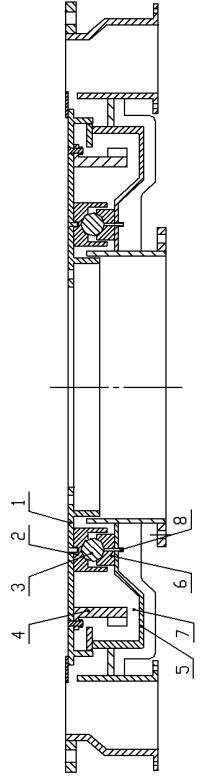

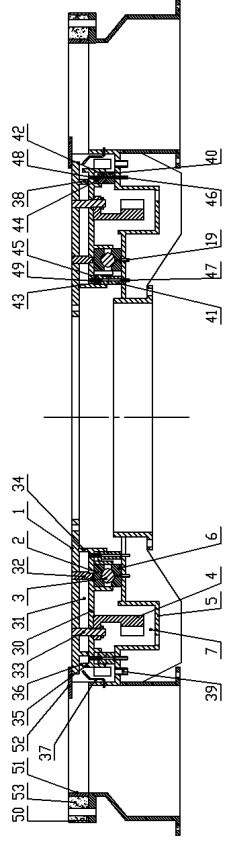

[0019] Embodiment one: if figure 2 As shown, the large ring gear inner transmission furnace bottom assembly of the present invention includes components such as ash tray 1, ball 3, large ring gear 4, furnace bottom shell 5, slideway and the like. The slideway is composed of a glideway 6 and an upper slideway 2, the upper slideway 2 is fixed on the ash tray 1, the glideway 6 is fixed on the furnace bottom shell 5, and the balls 3 are arranged on the upper slideway 2 corresponding to the glideway 6. Between the grooves, the large ring gear 4 is fixed under the ash tray 1 and is located outside the slideway, and extends into the groove 7 of the furnace bottom shell 5 and is connected with the pinion gear of the worm gear reducer fixed on one side of the furnace bottom shell 5 (not shown) to engage the drive. The outer upper end of the furnace bottom shell 5 is provided with a vertical refractory cement ring plate 50, an ash-proof fixing plate 51 and a horizontally arranged ash-...

Embodiment 2

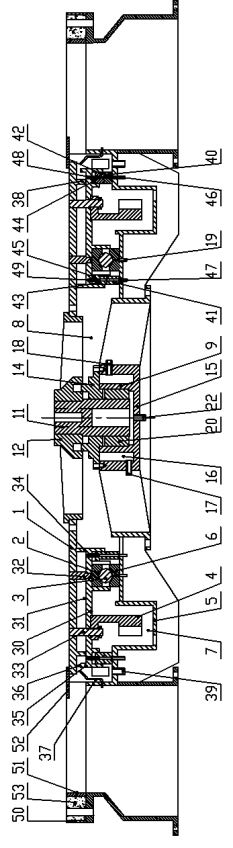

[0023] Embodiment two: if image 3 As shown, the difference from the first embodiment is that the bottom housing 5 and the central hole 8 of the ash tray 1 are provided with an ash tray limiting device, and the upper and lower parts of the ash tray limiting device are connected with the ash tray 1 and the furnace bottom respectively. The shell 5 is fixedly connected, and the top and bottom of the ash tray stopper are rotatably connected by a vertical shaft 11, and the centerline of the vertical shaft 11 coincides with the centerline of the center hole 8 of the furnace bottom shell 5 and the ash tray 1.

[0024]The ash tray limiting device includes a static bearing box assembly fixedly connected to the furnace bottom shell 5, a connecting piece 12 fixedly connected to the ash tray 1, the upper part of the vertical shaft 11 is inserted in the central hole of the connecting piece 12, and the lower part of the vertical shaft 11 is inserted into the center hole of the connecting pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com