Process for quickly breaking cell walls of Chinese wolfberry seeds and extracting seed oil

An extraction process and technology of wolfberry seeds, which are applied in the direction of fat oil/fat production and fat production, can solve the problems of large molecular weight and lowering, and achieve the effects of low extraction temperature, reduced extraction time, and easy industrial promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

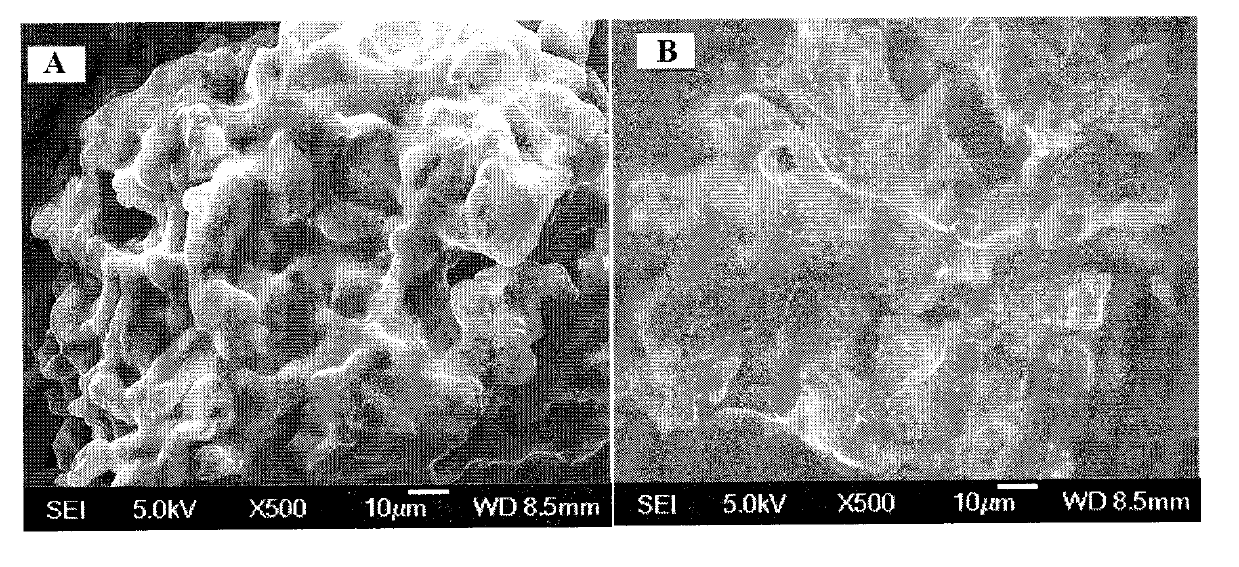

Image

Examples

Embodiment 1

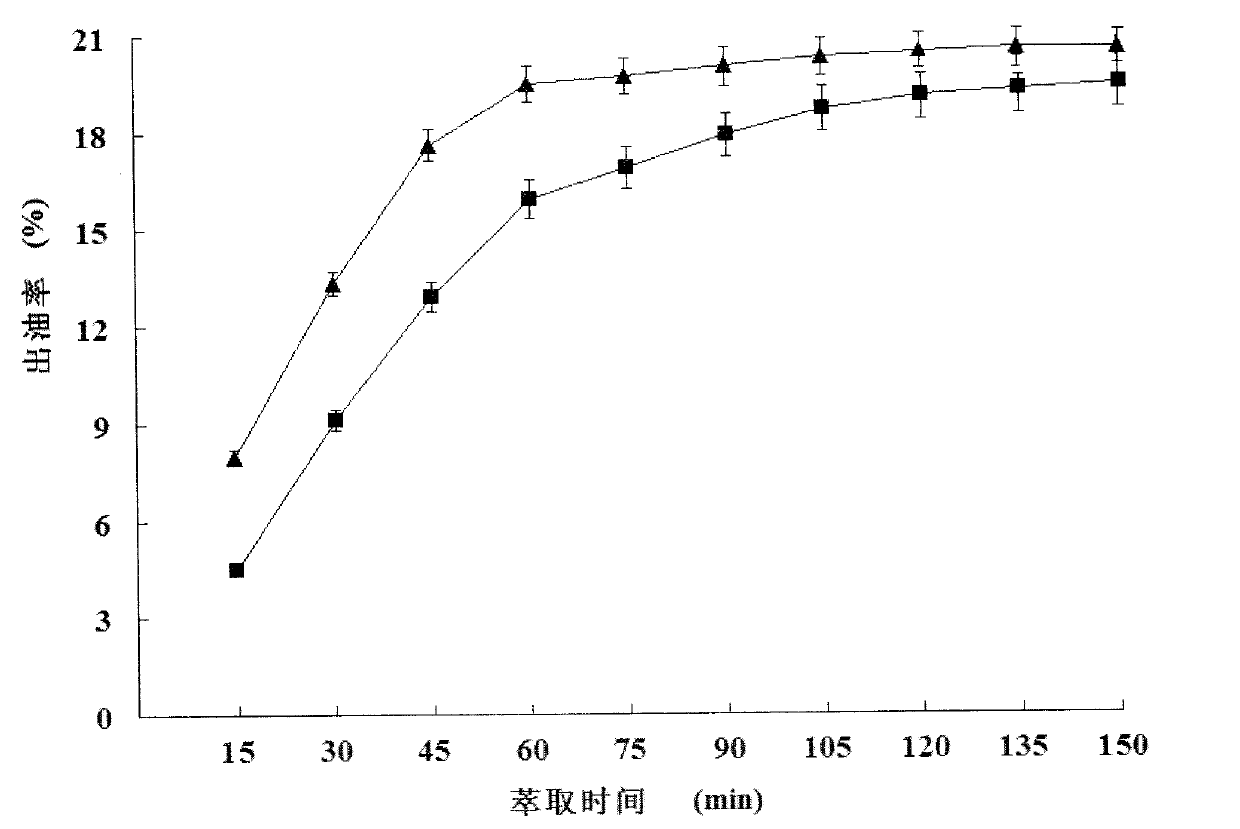

[0023] Embodiment 1 Lycium barbarum seed cell rapid wall breaking and seed oil extraction process comprise the following steps:

[0024] (1) Lycium barbarum seed cell wall breaking treatment: After the washed and dried wolfberry seeds are crushed to a particle size of 20 mesh, they are placed in the extraction kettle; CO is introduced into the extraction kettle. 2 , after raising the pressure in the extraction kettle to 40 MPa at normal temperature, keep it for 15 minutes; then close the inlet valves at both ends of the extraction kettle, and drop the pressure in the extraction kettle to atmospheric pressure within 1 minute to obtain the broken wolfberry seeds.

[0025] (2) pack the Lycium barbarum seeds after the broken wall of step (1) gained in the extraction kettle, pass into CO simultaneously 2 , the extraction kettle pressure is 28.5Mpa, temperature is 40.2 ℃, the consumption of entrainer ethanol (mass concentration is 95%) adds 6.88mL, CO 2 The flow rate is 50L / h under...

Embodiment 2

[0027] Embodiment 2 Lycium barbarum seed cell rapid wall breaking and seed oil extraction process comprise the following steps:

[0028] (1) Lycium barbarum seed cell wall breaking treatment: After the washed and dried wolfberry seeds are crushed to a particle size of 60 mesh, they are placed in the extraction kettle; CO is introduced into the extraction kettle. 2 After raising the pressure in the extraction kettle to 45 MPa at normal temperature, keep it for 10 minutes; then close the inlet valves at both ends of the extraction kettle, and drop the pressure in the extraction kettle to atmospheric pressure within 5 minutes to obtain the wolfberry seeds after the wall is broken.

[0029] (2) pack the Lycium barbarum seeds after the broken wall of step (1) gained in the extraction kettle, pass into CO simultaneously 2 , the extraction kettle pressure is 30.0Mpa, temperature is 45.0 ℃, the consumption of entrainer ethanol (mass concentration is 95%) adds 8.45mL, CO 2 The flow ra...

Embodiment 3

[0031] Embodiment 3 Lycium barbarum seed cell rapid wall breaking and seed oil extraction process comprise the following steps:

[0032] (1) Lycium barbarum seed cell wall breaking treatment: After the washed and dried wolfberry seeds are crushed to a particle size of 40 mesh, they are placed in the extraction kettle; CO is introduced into the extraction kettle. 2 After raising the pressure in the extraction kettle to 43 MPa at normal temperature, keep it for 12 minutes; then close the inlet valves at both ends of the extraction kettle, and drop the pressure in the extraction kettle to atmospheric pressure within 3 minutes to obtain the broken wall wolfberry seeds.

[0033] (2) pack the Lycium barbarum seeds after the broken wall of step (1) gained in the extraction kettle, pass into CO simultaneously 2 , the extraction kettle pressure is 29.0Mpa, temperature is 42.0 ℃, the consumption of entrainer ethanol (mass concentration is 95%) adds 7.50mL, CO 2 The flow rate is 35L / h u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com