Combined crucible for accommodating silicon materials

A combination and crucible technology, which is applied in the direction of polycrystalline material growth, crystal growth, chemical instruments and methods, etc., can solve the problems of low utilization rate of quartz crucibles, achieve waste utilization, increase filling factor, and high production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

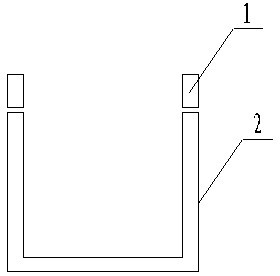

[0061] Embodiment 1. A combined crucible for containing silicon material, which includes an upper cover 1 and a lower crucible 2, the upper cover 1 is stacked directly above the lower crucible 2, wherein the upper cover 1 is surrounded by an upper side wall 3. The lower crucible 2 includes a lower side wall 4 and a bottom plate 5, the lower side wall 4 is distributed around the bottom plate, and the upper side wall 3, the bottom side wall 4 and the bottom plate 5 jointly enclose a cavity where materials can be placed.

Embodiment 2

[0062] Embodiment 2. A combined crucible for containing silicon material, which includes an upper cover 1, a lower crucible 2, and the upper cover 1 is directly stacked on the lower crucible 2, wherein the upper cover 1 is surrounded by an upper side wall 3 The lower crucible 2 includes a lower side wall 4 and a bottom plate 5, the bottom side wall 4 is distributed around the bottom plate, and the upper side wall 3, the bottom side wall 4 and the bottom plate 5 jointly enclose a cavity where materials can be placed.

Embodiment 3

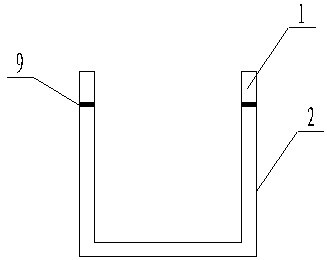

[0063] Embodiment 3. A combined crucible for containing silicon material, wherein: the adhesive 9 is spread between the upper cover 1 and the lower crucible 2. The rest is the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap