Filament tension control device for filament short-fiber composite spinning

A composite spinning and tension control technology, which is applied in textiles and papermaking, can solve problems such as incompetence, unstable pressure of filament a5, and tension changes, and achieve consistent performance, convenient and reliable tension adjustment, and stable tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

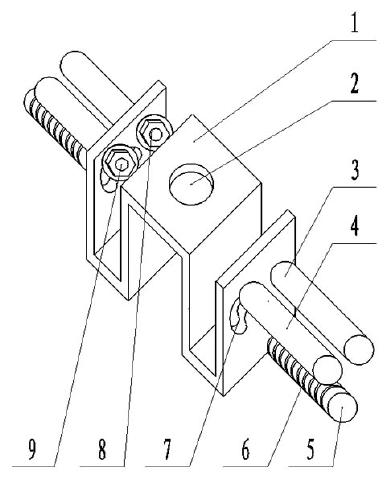

[0028] For the specific implementation of this device, see Figure 4 .

[0029] The special control device for filaments of the present invention is composed of three small shaft groups and a base frame (see figure 2 ). The upper tension roller 3, the movable tension roller 4 and the positioning tension roller 5 are combined with the base frame 1 through screws 8 and nuts 9 at their tails respectively. The movable tension roller 4 can adjust its position through the curved through groove 7 on the base frame 1 . Filament positioning grooves are distributed on the positioning tension roller 5 .

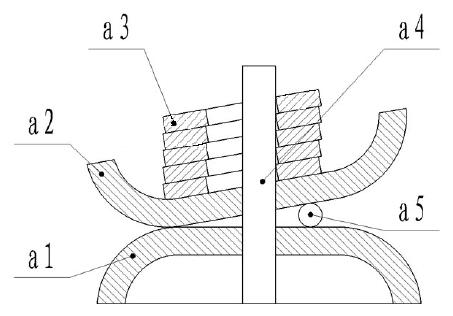

[0030] The base frame 1 rides on the cradle 14 of the spinning frame and is fixed on the cradle 14 of the spinning frame with screws 15 through the holes 2 . During spinning, long filament 13 exits from long filament bobbin 12, enters in the nip that front top roller 10 and roller 11 of spinning frame form through upper tension roller 3, movable tension roller 4 and positioning ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com