Mixing station of blending mechanism of road-building raw materials

A technology for mixing buildings and raw materials, applied in the direction of roads, roads, buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

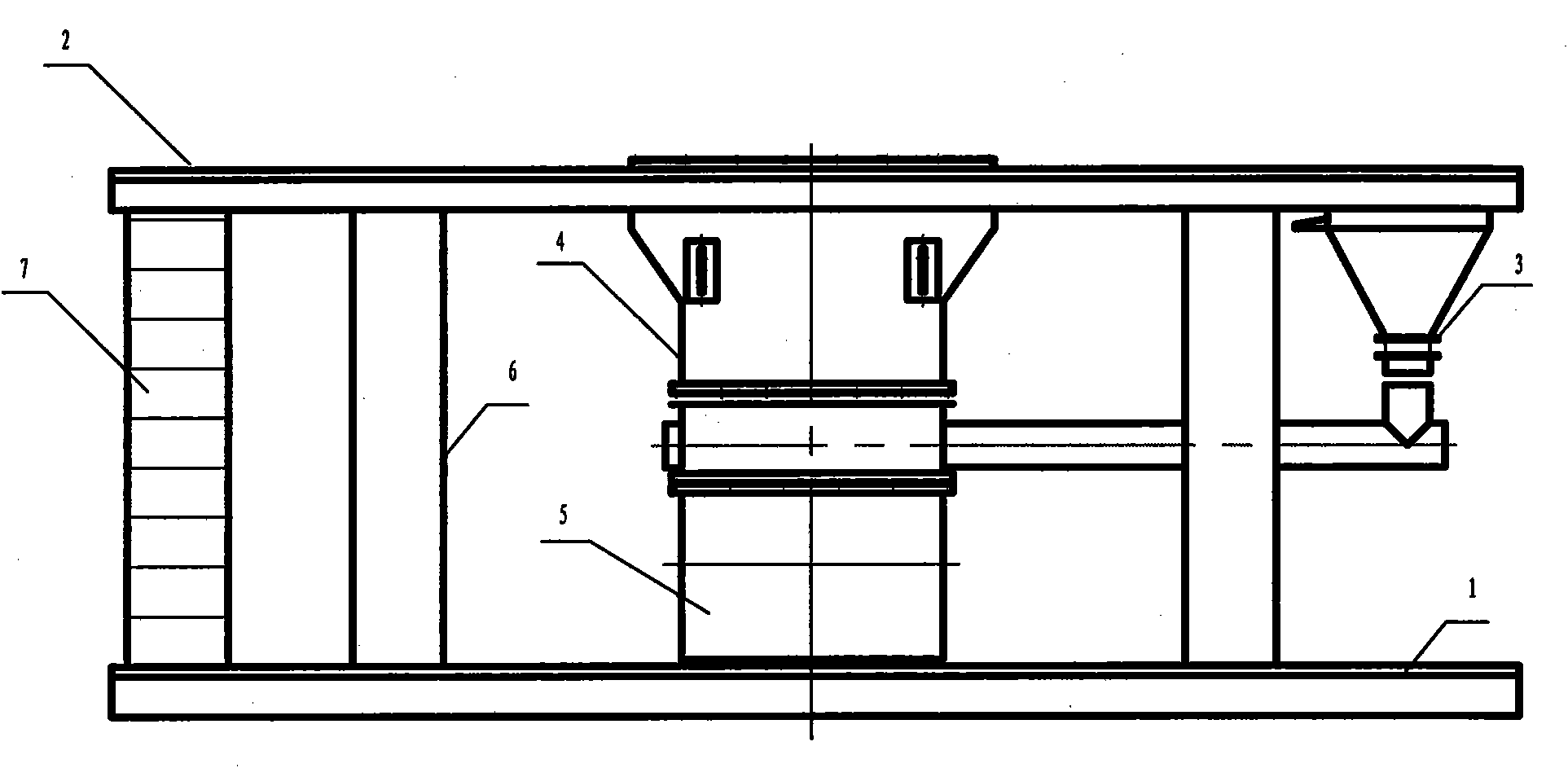

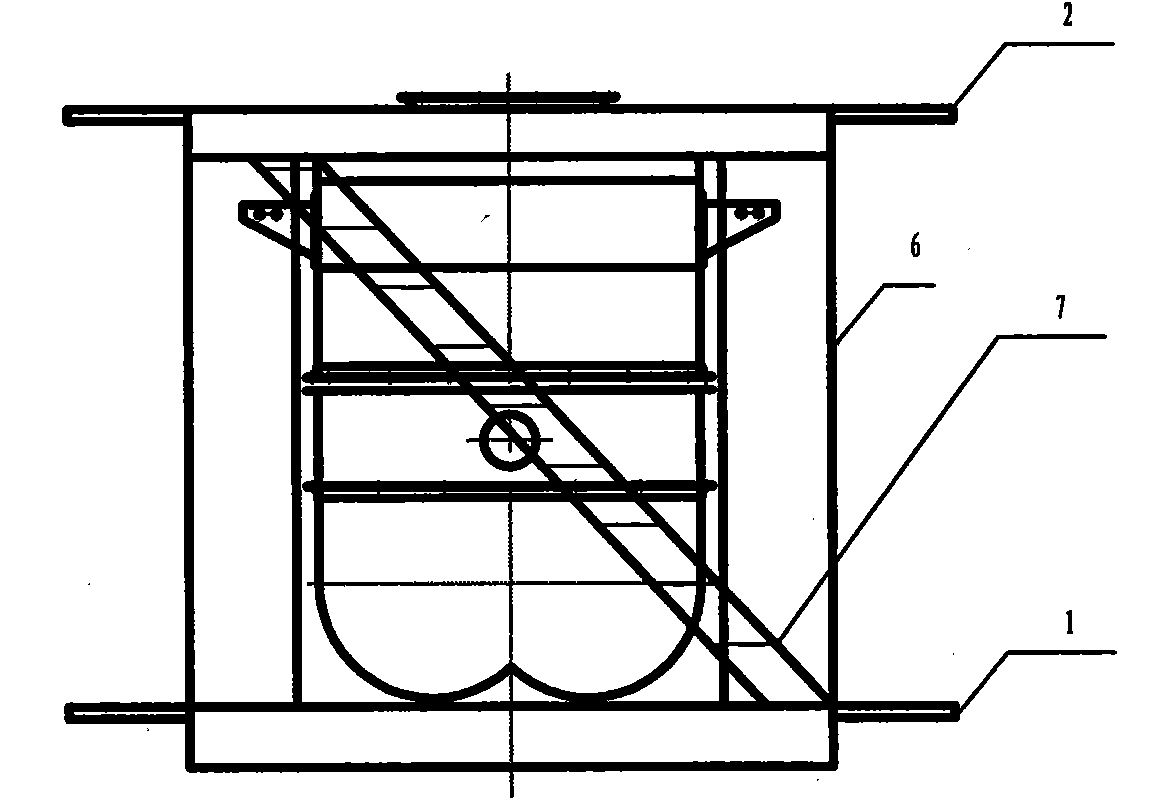

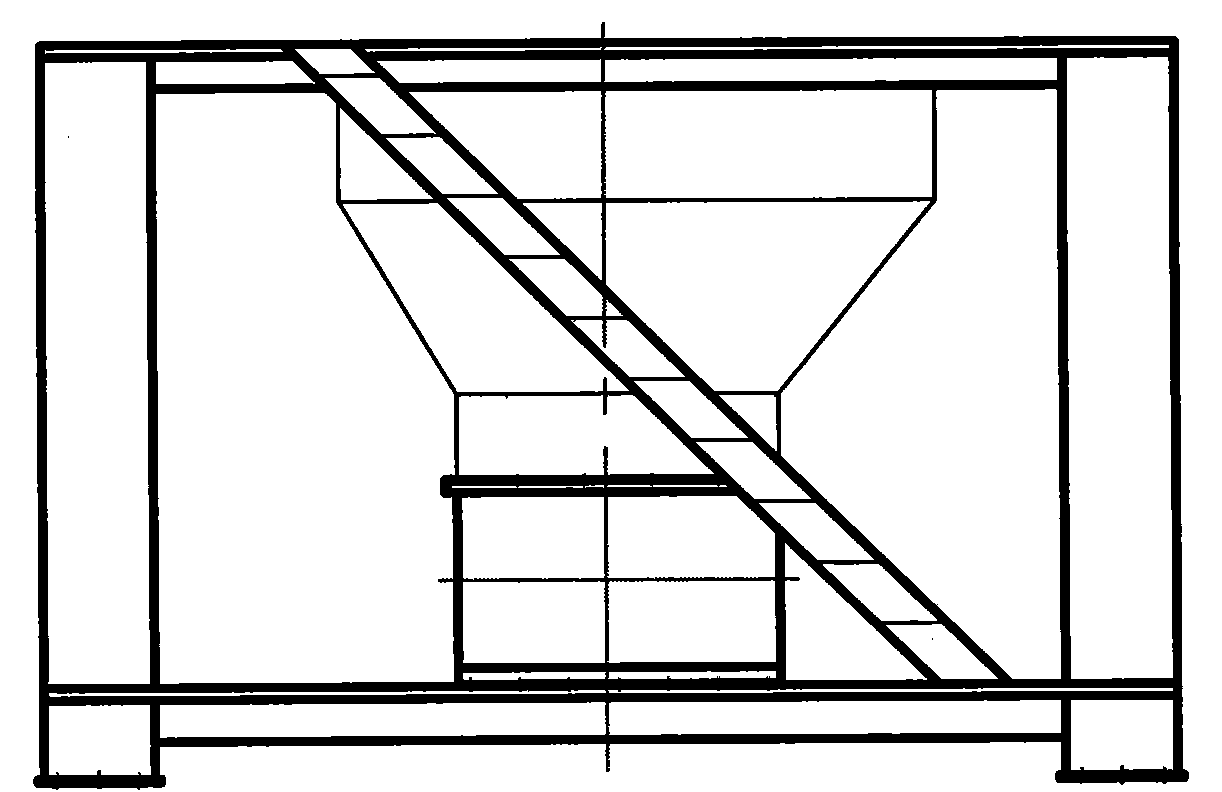

[0014] Such as figure 1 , figure 2 As shown, the mixing building of the road construction raw material mixing mechanism has a base 1 at the bottom, and an operating platform 2 fixed on the base 1 through a column 6 at the top. The stone metering system 4, the mineral powder metering system 3 and the mixing tank 5 are located Between the base 1 and the operating platform 2, the stone metering system 4 and the mineral powder metering system 3 are located above the mixing cylinder 5; between the base 1 and the operating platform 2, a ladder 7 is provided, and the ladder 7 is located outside the column 6 .

[0015] The operation platform of this mixing building is longer than the existing technology, and there is a ladder between the operation platform outside the column and the base. The built-in ladder makes the whole platform walk smoothly and is easy to maintain. The equipment looks neat, beautiful and atmospheric. At the same time, it also meets the modification requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com