Method for correcting inclined hole formed by high strength stratum bridge drilling pile in karst growing area

A high-strength, bored pile technology, applied in sheet pile walls, directional drilling, construction, etc., can solve problems such as labor disputes, high costs, slow progress, etc., to speed up project progress, save investment, and have broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

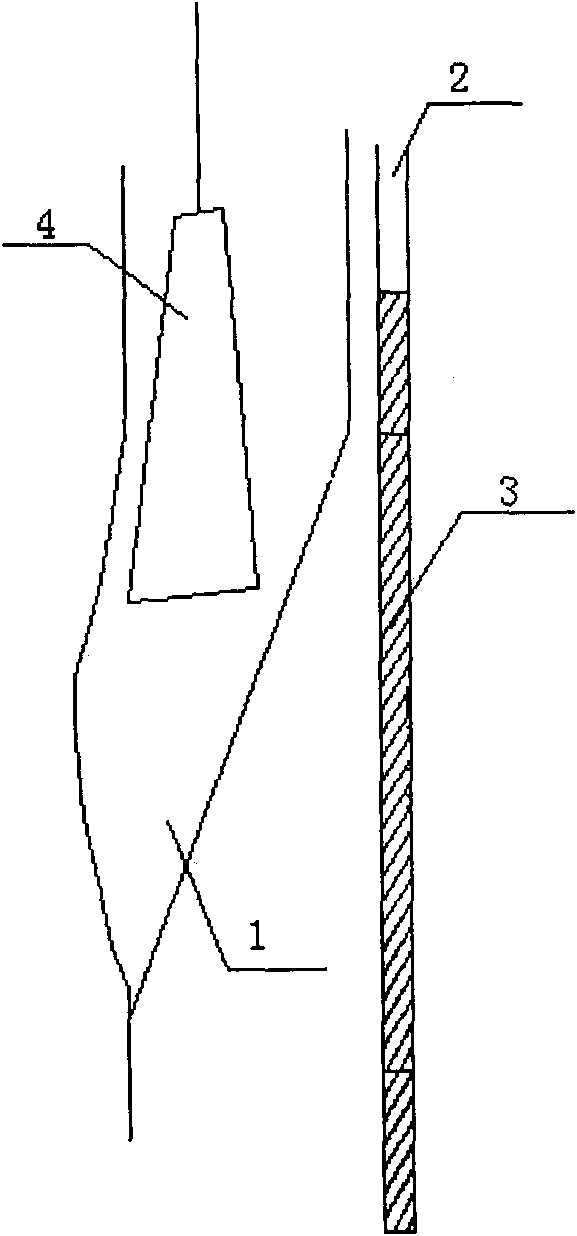

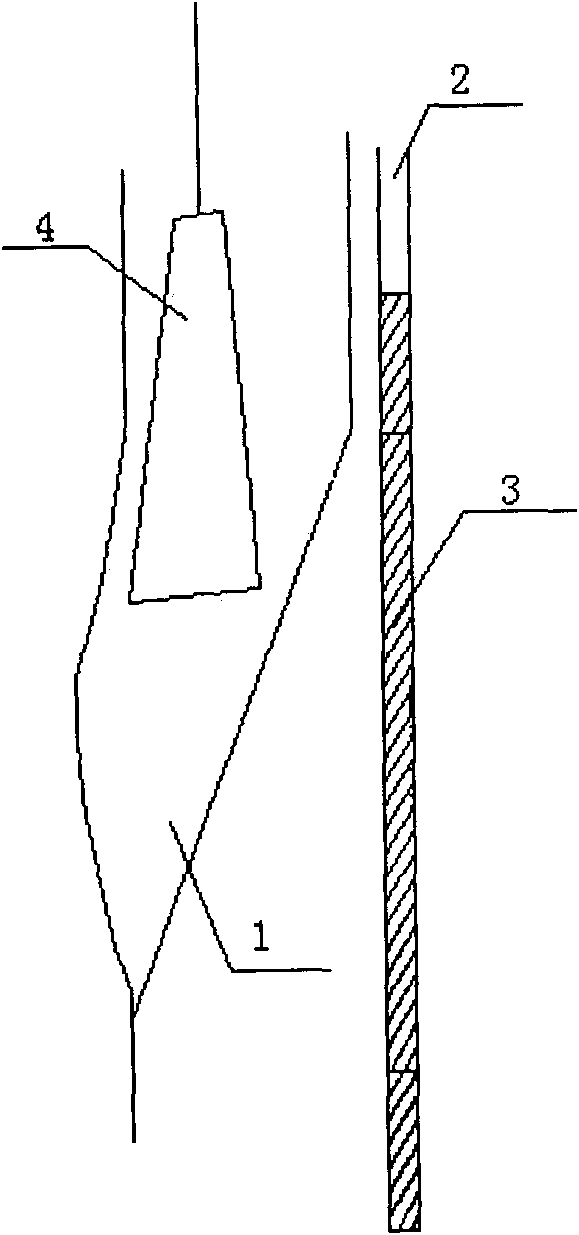

[0022] Such as figure 1 As shown, a method for rectifying the deviation of the inclined hole of the high-strength rock formation bridge bored pile in the karst developed area is characterized in that the method is composed of the following steps:

[0023] (1) Verify the location of the inclined rock to determine the exact position and direction of the inclined rock;

[0024] (2) Use a small geological drilling rig to drill a small hole on the top of the inclined rock next to the inclined hole;

[0025] (3) Waterproof explosives are sent into the underwater small hole;

[0026] (4) Carry out underwater controlled blasting to break or loosen rock formations;

[0027] (5) Then use the percussion drill to impact the broken or loose rock formation, so as to correct the deviation of the drilling hole and quickly form a hole.

[0028] The position of the small hole drilled by a small geological drilling rig is 200-300mm from the top of the inclined rock next to the inclined hole, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com