Anti-rotation self-locking rubber plug used for well cementation

A self-locking and rubber plug technology, used in wellbore/well components, earth-moving drilling, sealing/packing, etc., can solve problems such as increasing drilling cost, increasing drilling cycle, casing wall wear, etc., to improve efficiency, The effect of saving drilling time and reducing drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

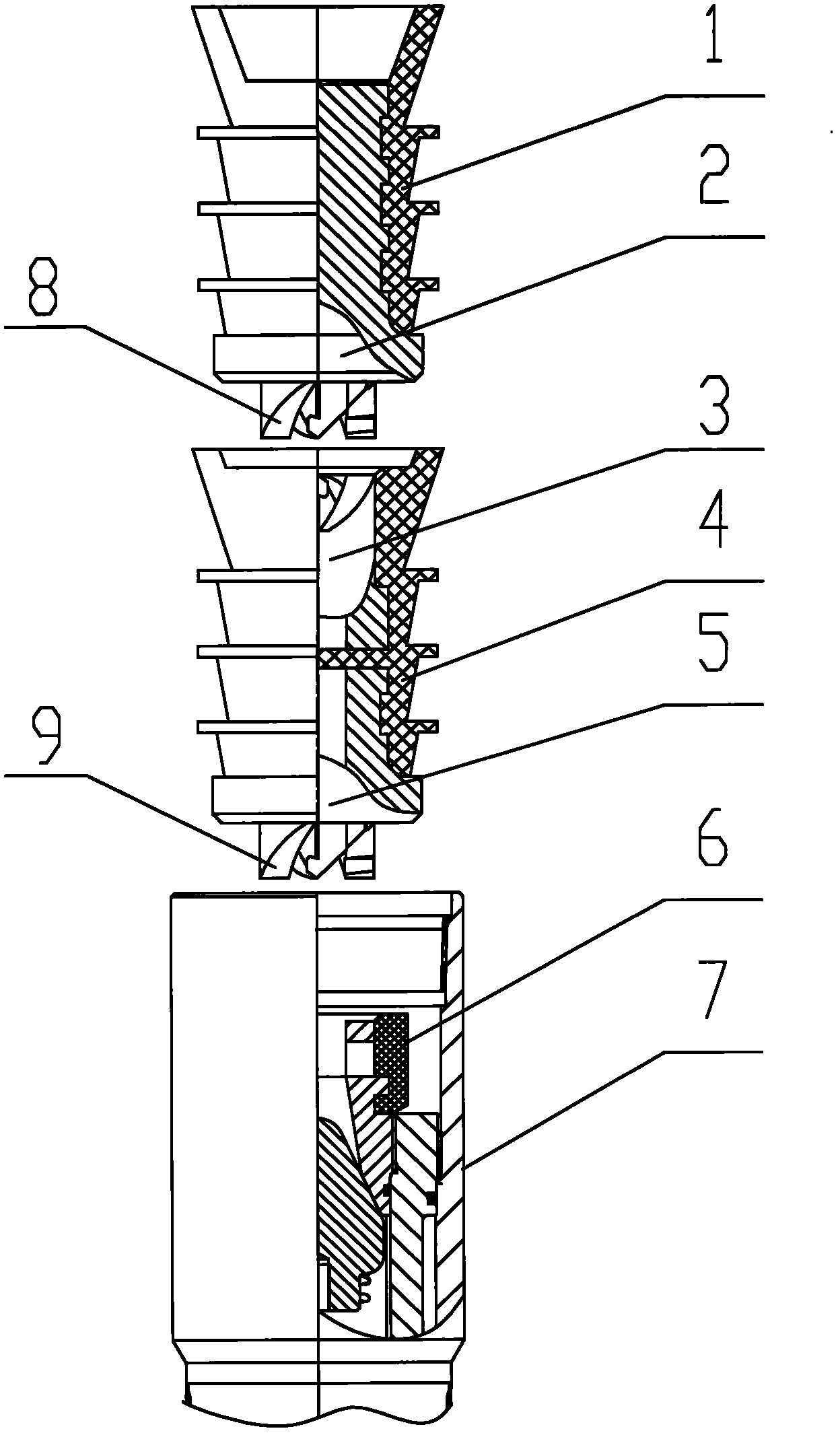

[0014] The structure of the present invention includes three parts: the upper rubber plug, the lower rubber plug and the floating hoop. Rubber discs 1 and 4 are arranged on the upper rubber plug and the lower rubber plug, and a self-locking core 2 is arranged at the lower end of the upper rubber plug. In order to connect with the self-locking of the lower rubber plug, the self-locking core 2 provided at the lower end of the upper rubber plug is four positive hook teeth 8 distributed according to a 90° phase; The lock core 5, the upper self-lock core 3 of the lower rubber plug is four anti-hook teeth distributed according to the 90° phase, and the lower self-lock core 5 of the lower rubber plug is four positive hook teeth 9 distributed according to the 90° phase; The floating hoop 7 is provided with a floating hoop self-locking core 6, and the floating hoop self-locking core 6 is an anti-hook tooth distributed according to a 90° phase;

Embodiment 2

[0016] The connection of the present invention is: the positive hook tooth 8 of the self-lock core 2 at the lower end of the upper rubber plug is hooked and locked with the anti-hook tooth 8 of the upper self-lock core 3 provided at the upper end of the lower rubber plug, and the lower self-lock core provided at the lower end of the lower rubber plug The positive hook teeth 9 of 5 are hooked and locked with the four anti-hook teeth of the self-lock core 6 of the floating hoop. The rubber discs 1 and 4 set on the upper rubber plug and the lower rubber plug are made of rubber. At this time, the annular surface of the upper and lower rubber plugs in contact with the sleeve is always squeezed and deformed, so that the upper and lower rubber plugs can not only lock each other to prevent rotation, but also rely on the extrusion deformation of the annular surface to produce a sealing effect to withstand the reverse pressure.

Embodiment 3

[0018] A specific application example of the present invention: a test was carried out in a well in Sichuan oil and gas field, the well depth was 1790m, and a casing pipe with an outer diameter of 177.8mm and a wall thickness of 9.19mm was lowered into a casing of 1788m. The displacement and pressure are stable, and there is no backflow phenomenon in the pipe after being pressed in place, and the rubber plug and floating hoop are effectively sealed; the drilling time of the three-split drilling well is 19 minutes with a 152.4mm roller cone bit, compared with the average time of 240 minutes for the same type of well conditions Save 130 minutes;

[0019] In the implementation process, the positive hook teeth 8 of the self-locking core 2 at the lower end of the upper rubber plug can be locked with the anti-hook teeth 8 of the self-locking core 3 at the upper end of the lower rubber plug, and the lower self-locking core 5 at the lower end of the lower rubber plug The positive hook...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap