Filling simulator for salt rock cavern

A technology of simulation device and salt chamber, which is applied in the test field of water-soluble mining of salt deposits, can solve problems such as no public reports, and achieve the effect of backfilling process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

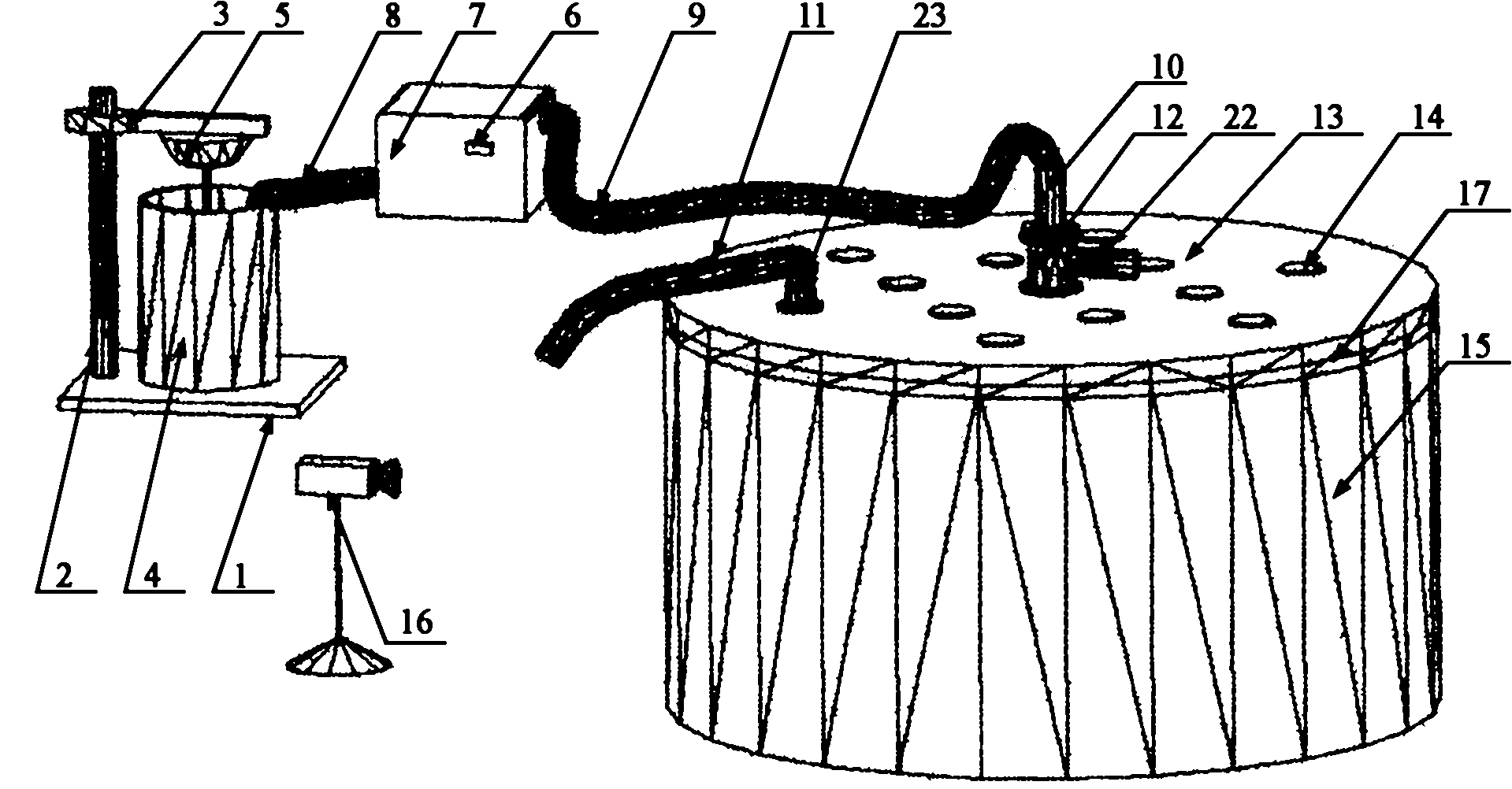

[0057] Example 1: Determination of the optimal concentration of slurry when filling a single cavity.

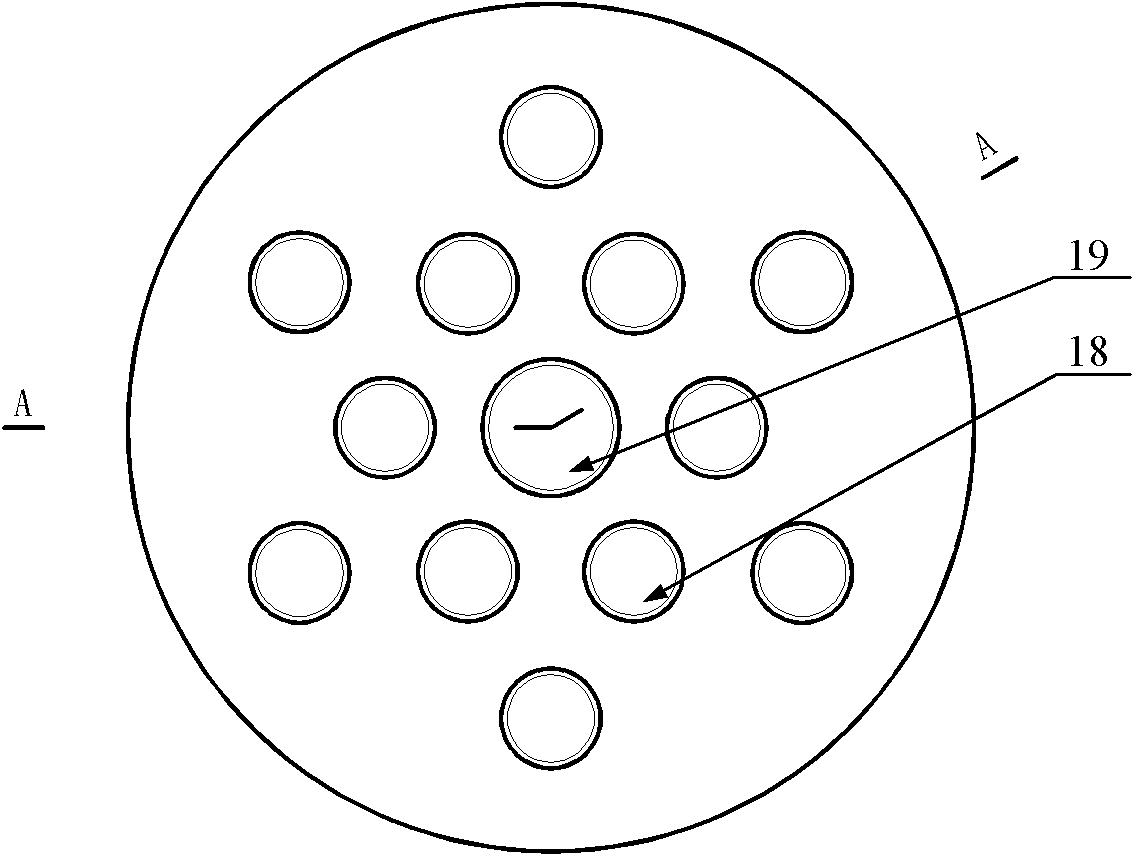

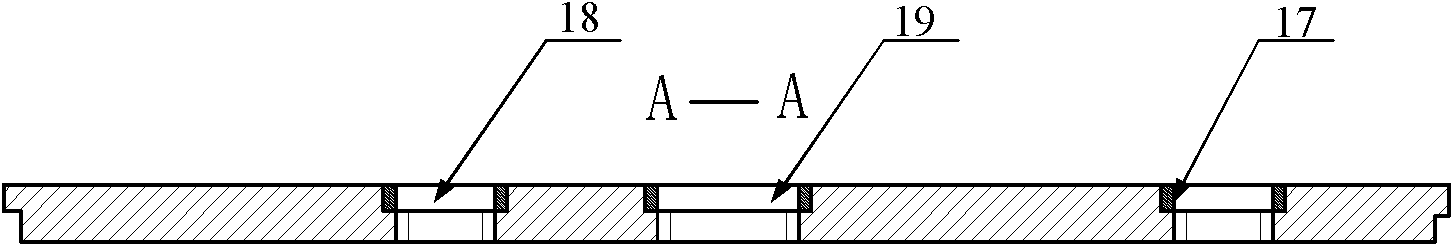

[0058] One end of the slurry delivery hose 8 is connected to the inlet of the peristaltic pump 7 , one end of the slurry delivery hose 9 is connected to the outlet of the peristaltic pump 7 , and one end is connected to the central tube 10 . The auxiliary port plug 14 is screwed to all the auxiliary ports 18 on the chamber cover 13, the sleeve pipe 12 is screwed to the main port 19, the sleeve pipe 12 is provided with a liquid leakage groove 21 and the end is downward, and the liquid outlet 22 on the sleeve pipe 12 is connected with the External hose connection to waste. The cavity cover 13 is screwed onto the filling cavity 15, the central tube 10 is inserted into the casing 12, the central tube 10 is adjusted, and the bottom distance of the tube is fixed.

[0059]The filling chamber 15 is filled with brine. Pour industrial waste and brine into the mixing chamber 4 accordi...

example 2

[0062] Example 2: Determination of the optimum tube-to-bottom distance during double-cavity filling.

[0063] In the first mining area of a salt mine, double-cavity mining is carried out by using the straight-flow method of wells. The well spacing is 74.78m, the average cavity height is 50m, and the simulated filling cavity height is 0.5m. According to the similar relationship, the distance between the two holes selected in the cavity cover 13 should be 0.75m. After measurement, there are two auxiliary ports with a distance of 0.75m.

[0064] Both the unused auxiliary port 18 and the main port 19 are tightened with the auxiliary (main) port plug 14. Take two auxiliary port hollow plugs 23, screw them on the selected auxiliary port, insert the central tube 10 into one of the auxiliary port hollow plugs 23, the outer end of the central tube 10 is connected to one end of the slurry delivery hose 9, and the liquid outlet hose 11 is inserted into the The other is a pair of hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com