Heat accumulating type heating furnace totally using blast furnace gas as fuel

A blast furnace gas and heating furnace technology, which is applied to the field of heating furnace combustion, can solve the problems of complicated on-site piping and layout, dirty on-site environment, and high implementation cost, and achieves the effects of simple implementation, low cost, and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

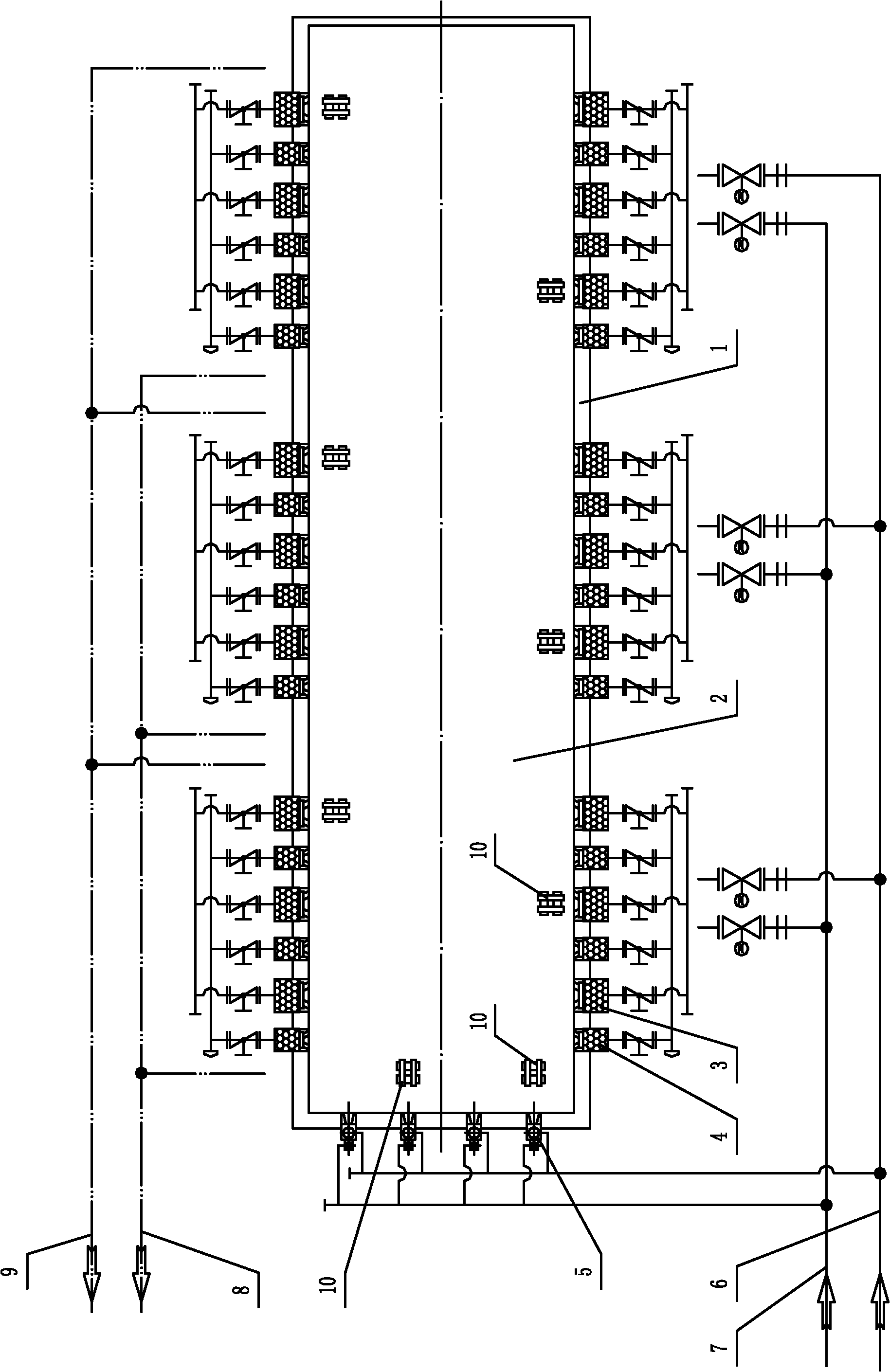

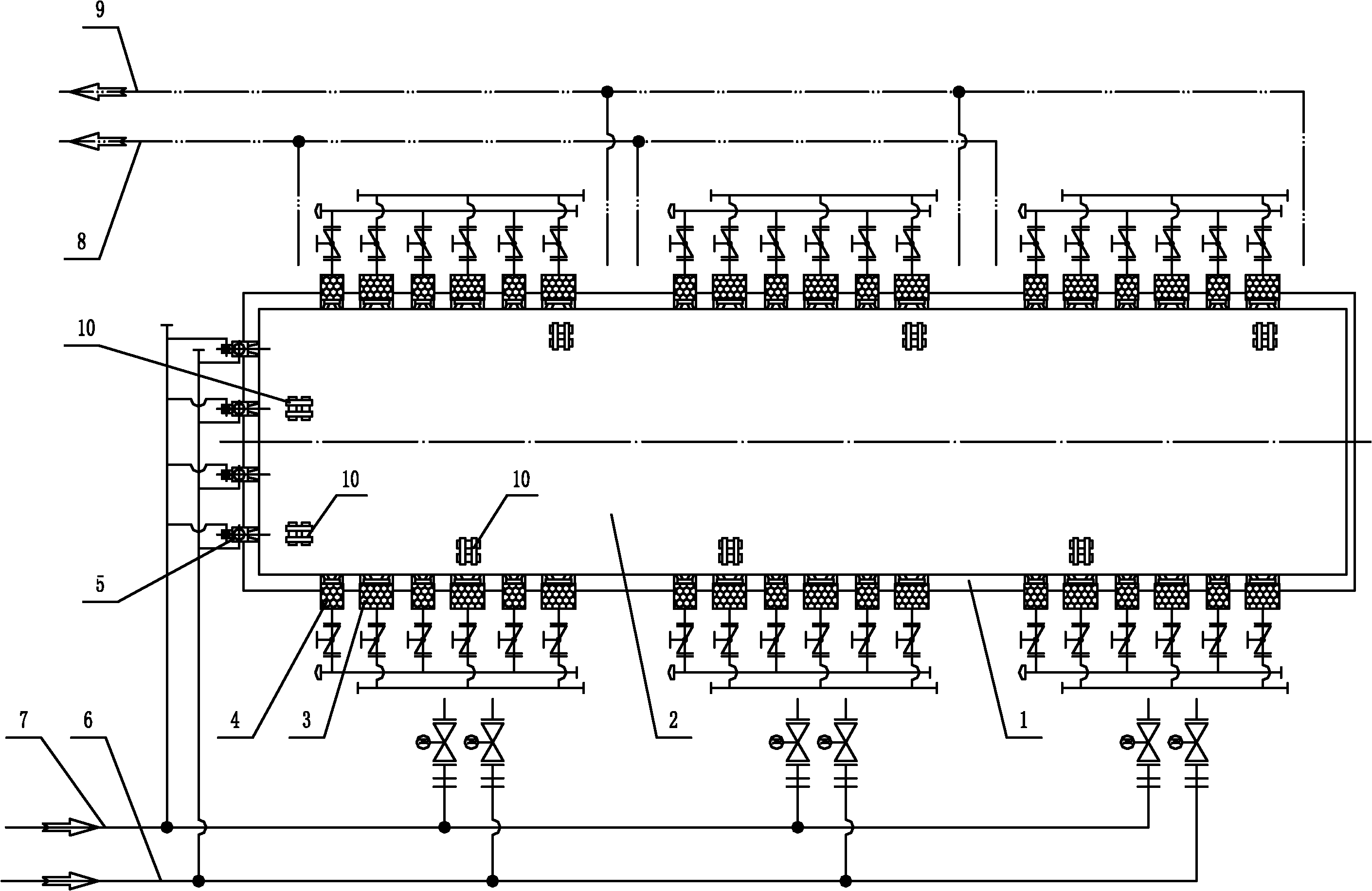

[0014] Such as figure 1 As shown, all the regenerative heating furnaces using blast furnace gas as fuel include heating furnace body 1, blast furnace gas regenerator 3, air regenerator 4, blast furnace gas ignition burner 5, blast furnace gas pipeline system 6, Combustion-supporting air piping system 7, air side smoke exhaust piping system 8, gas side smoke exhaust piping system 9; heating furnace body 1 is heating furnace hearth 2, and heating furnace hearth 2 is divided into multiple heating sections such as soaking section and heating section section; blast furnace gas regenerator 3 and air regenerator 4 are installed on both side walls of the heating furnace body 1, and the blast furnace gas ignition burner 5 is installed on the end wall or side wall of the soaking section of the heating furnace body 1 Above: the nozzles of the blast furnace gas regenerator 3 and the air regenerator 4 are respectively connected with the furnace 2 of the heating furnace, and the blast furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com