Large-capacity preparation flow cell with optical fiber interface

A technology of optical fiber interface and flow cell, which is applied in the field of liquid chromatography, can solve the problems that the explosion-proof requirements cannot be met, and the optical path cannot be adjusted, so as to achieve the effects of conveniently adjusting the optical path, reducing the loss of light energy, and facilitating the discharge of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

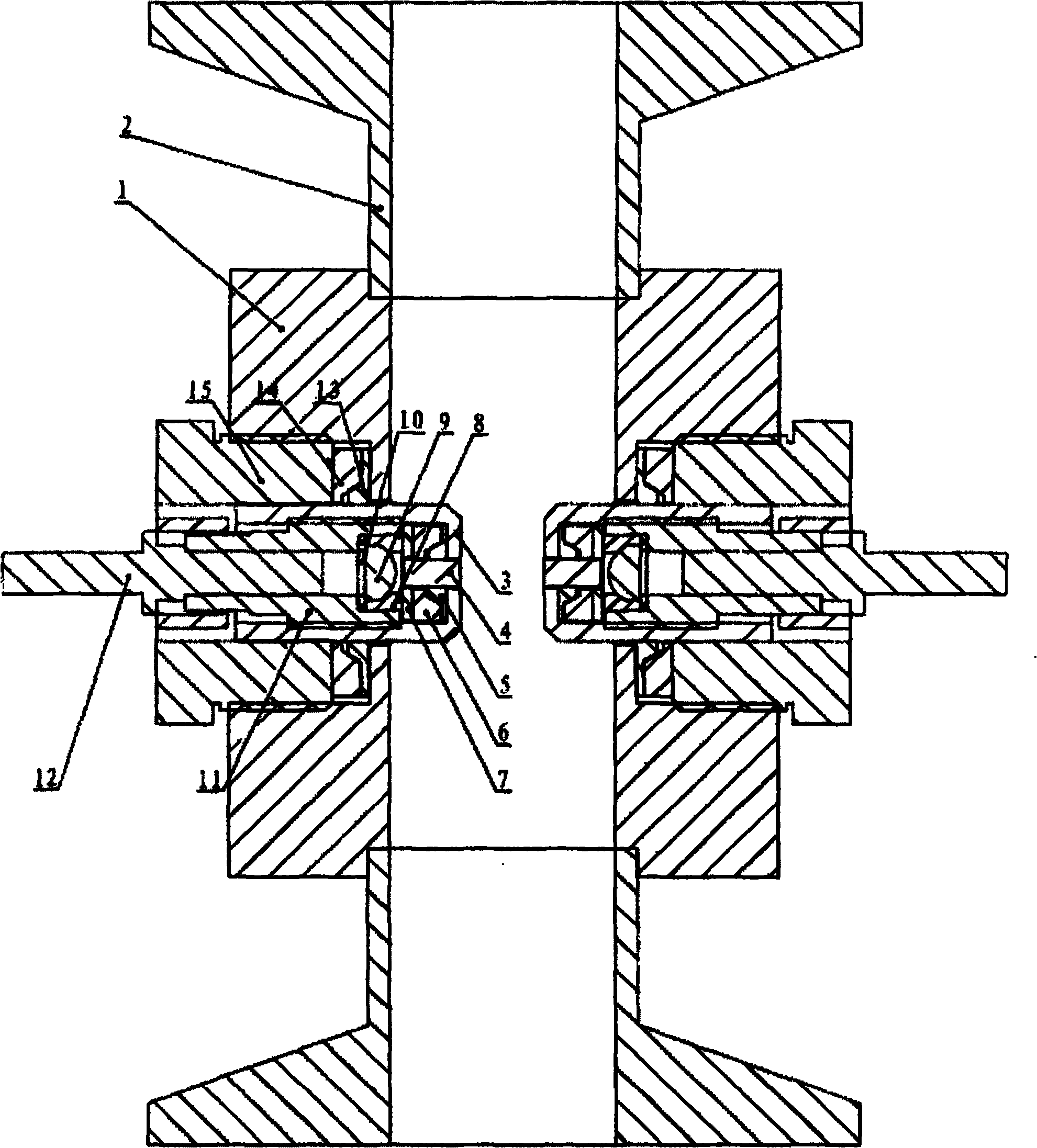

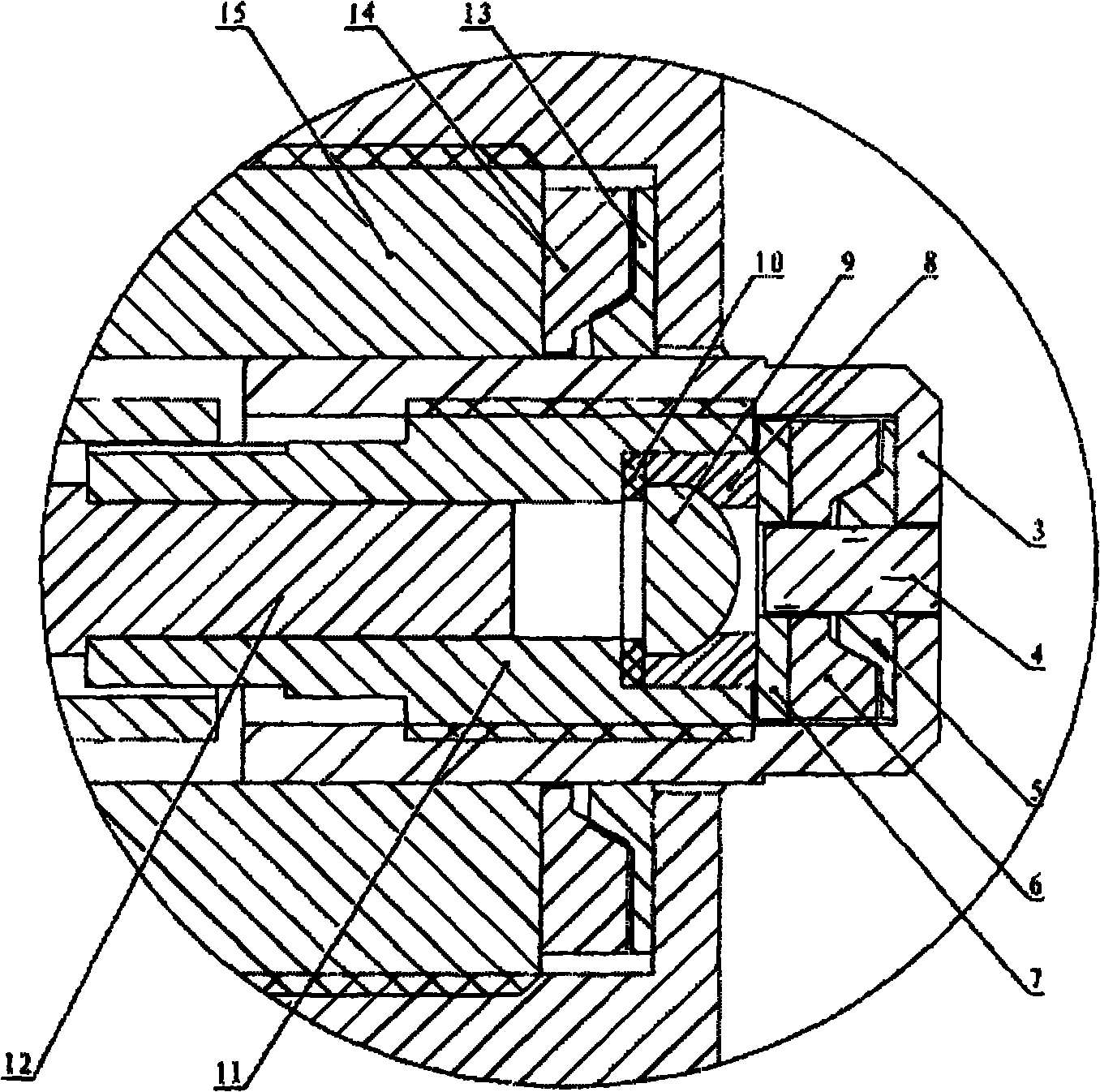

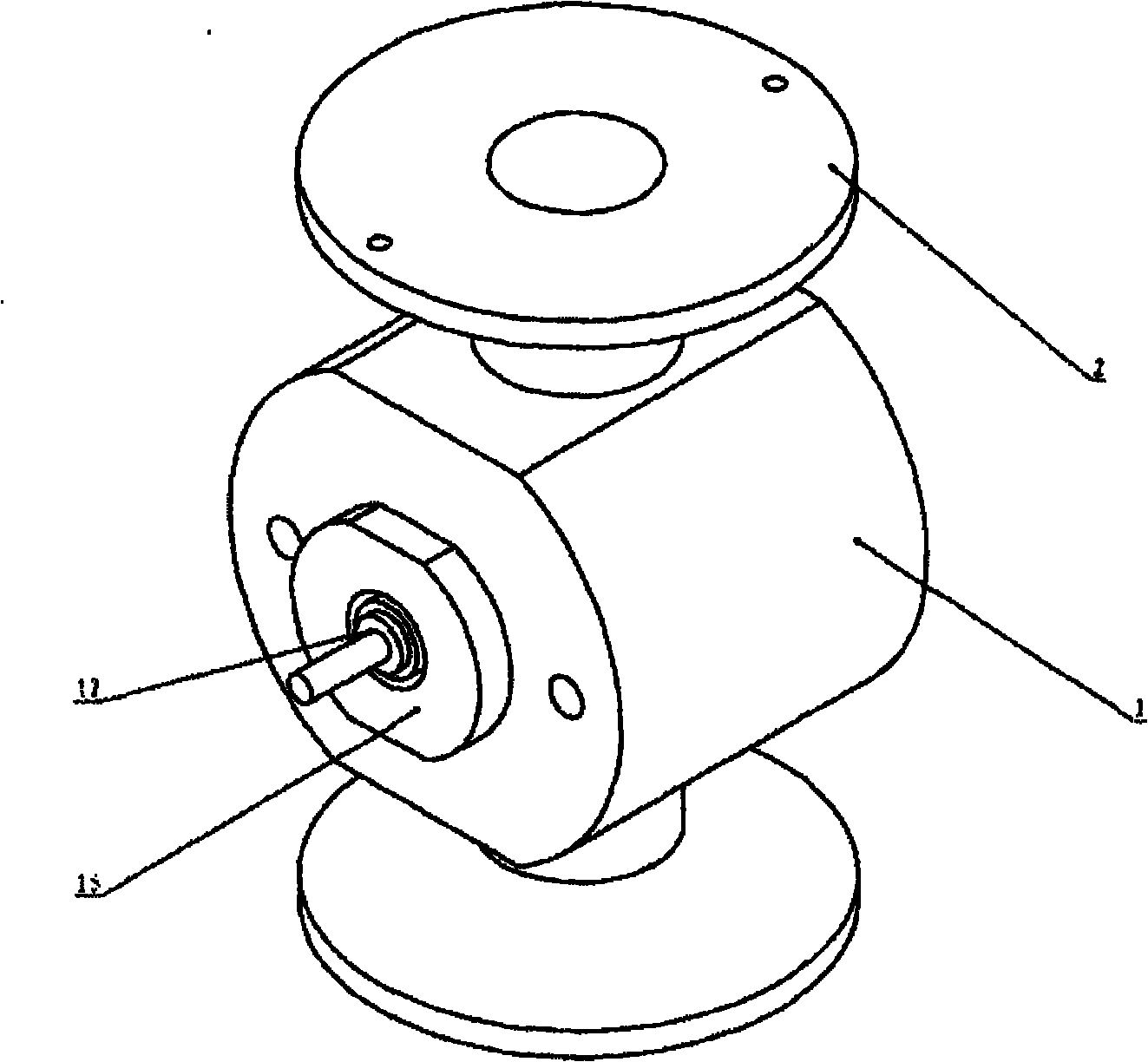

[0028] The present invention a kind of flow cell of optical fiber interface large flow preparation, such as figure 1 , figure 2 As shown, the flow cell consists of a flow cell body 1, a flange joint 2, an adjustment rod 3, a quartz light column 4, a light column sealing gasket 5, a light column sealing pressure plate 6, a light column adjustment sheet 7, a plano-convex lens seat 8, a plano-convex lens 9, It consists of a plano-convex lens gasket 10, an optical fiber adapter 11, a standard optical fiber connector 12, an adjusting rod sealing gasket 13, an adjusting rod sealing pressure plate 14 and a pool nut 15.

[0029] Such as image 3 As shown, the flange joint 2 is welded on the upper and lower ends of the flow cell body 1, and the middle through hole is used for the passage of liquid, and the diameter of the through hole is larger than that of the adjusting rod 3 ( Figure 4 )diameter of.

[0030] return figure 1 with figure 2 , the adjustment rod 3 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com