Storage battery heat shield

A technology for batteries and heat shields, which is applied to battery components, circuits, electrical components, etc., which can solve the problems of high battery layout space requirements and high temperature, and achieve the effects of saving installation space, simple manufacture, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

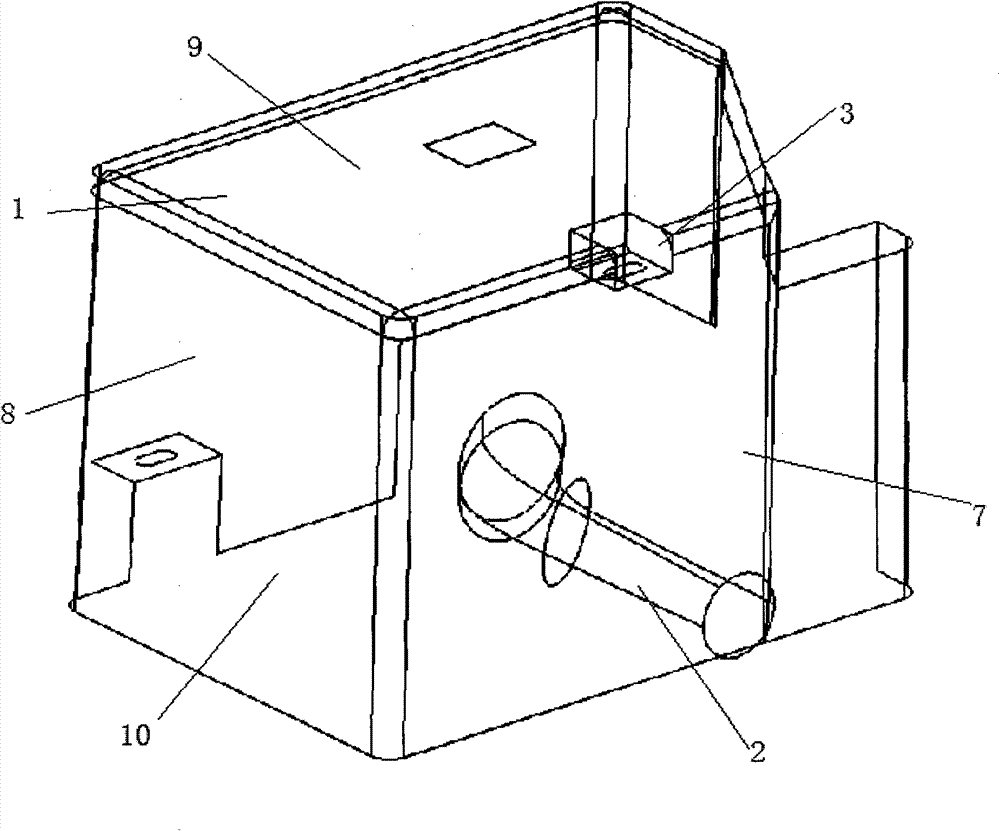

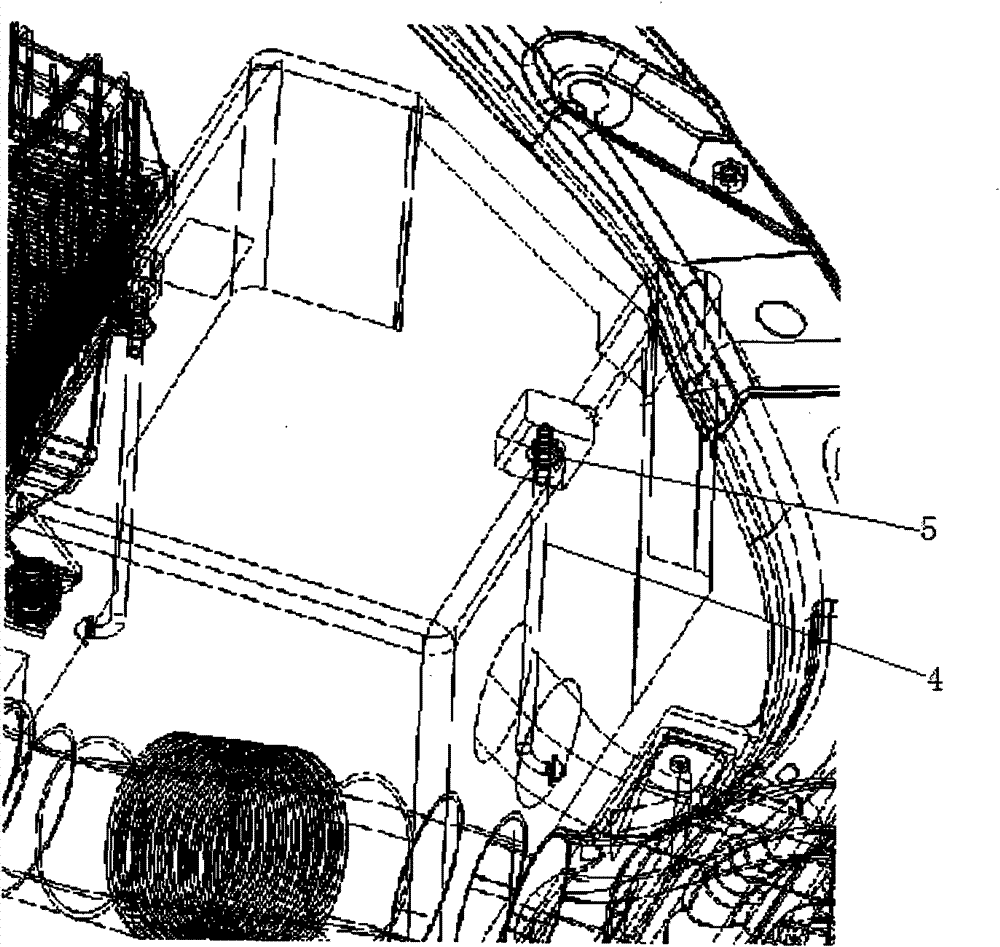

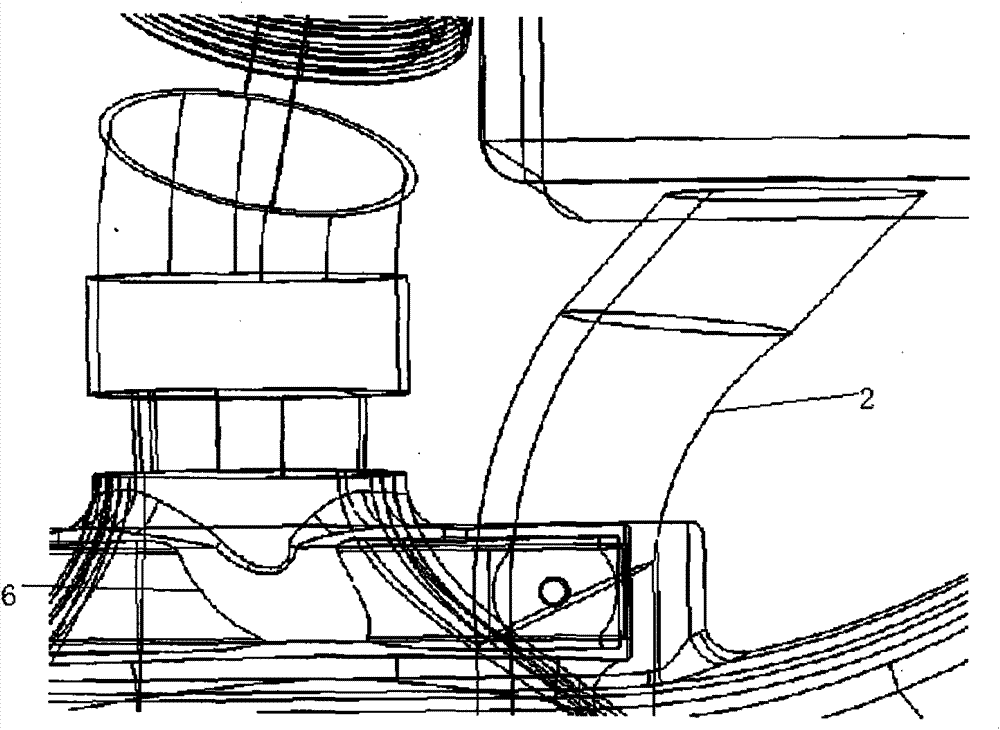

[0022] Attached below Figure 1-3 , the present invention is further described:

[0023] as attached figure 1 As shown, the battery heat shield designed in the present invention is composed of two parts: the battery heat shield body 1 and the battery intake pipe 2; the heat shield body 1 includes a front 7, a side 10, a back 8 and a top 9, wherein the front 7 , the side 10 and the back 8 wrap the storage battery on three sides. The battery intake pipe 2 is arranged on the front 7 of the heat shield body 1, and the battery intake pipe 2 is connected to the air filter 6; a mounting groove 3 is provided on the intersection line between the top surface 9 and the front surface 7 of the heat shield body 1 The pressure plate connecting rod 4 on the front of the battery passes through the installation groove 3, and part of the screw rod is exposed, and the fixed connection between the battery heat shield and the battery is realized by connecting the fixing nut 5 to the exposed screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com