Pipe connector device

A connector and tubular technology, used in drill pipes, casings, couplings, etc., can solve the problems of excessive tooth wear and high contact pressure, reduce wear, simplify machining and inspection requirements, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

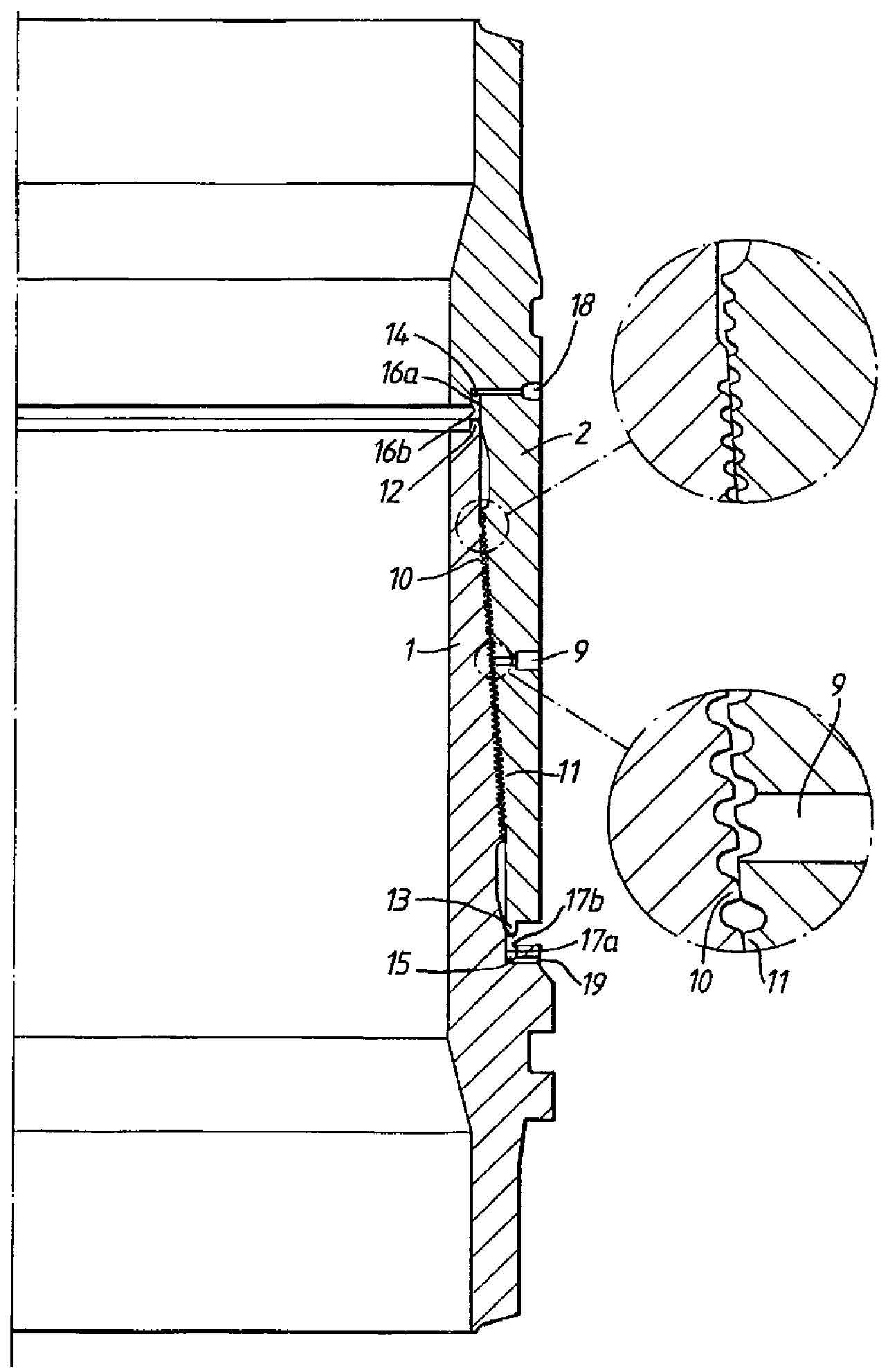

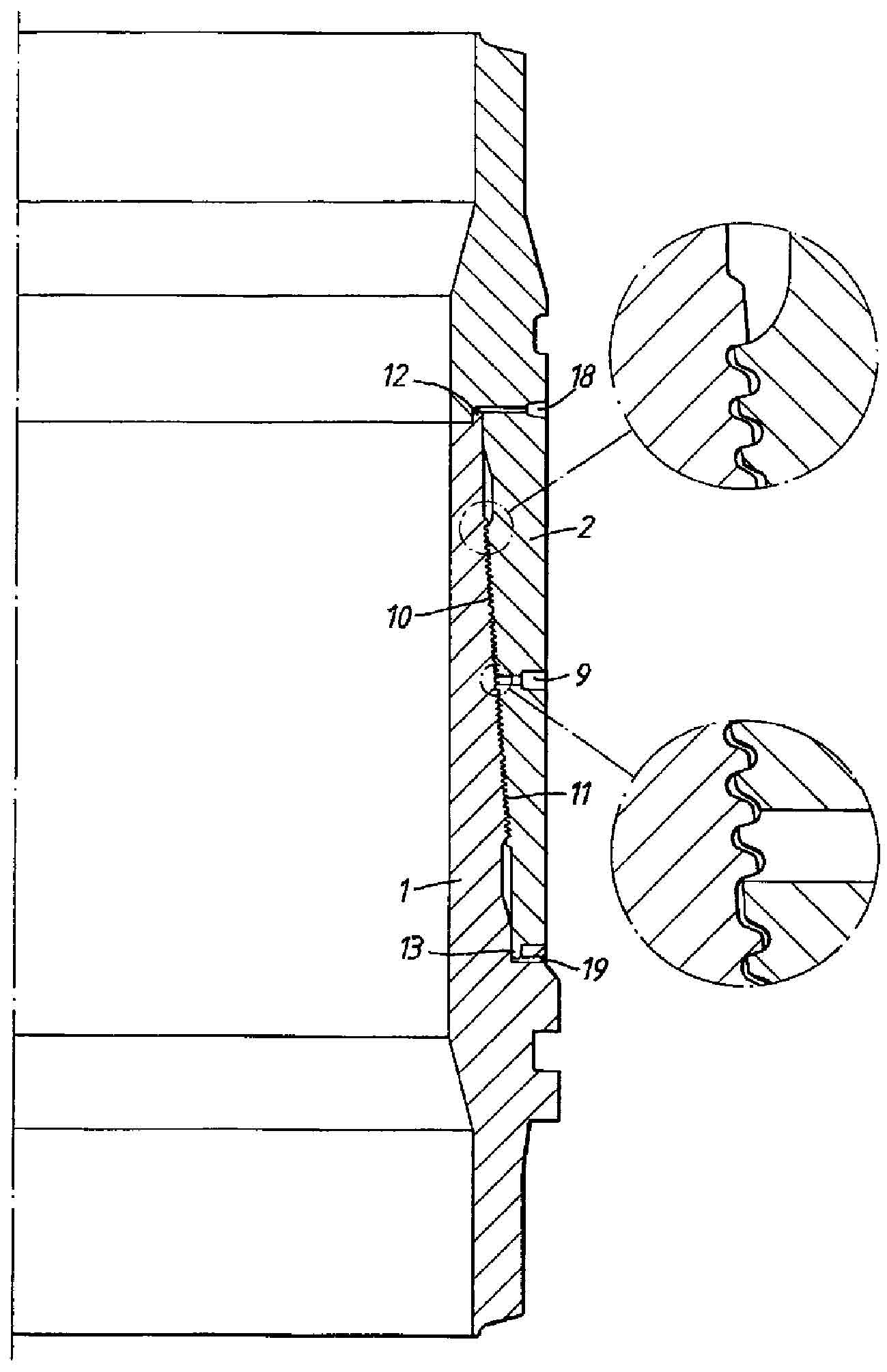

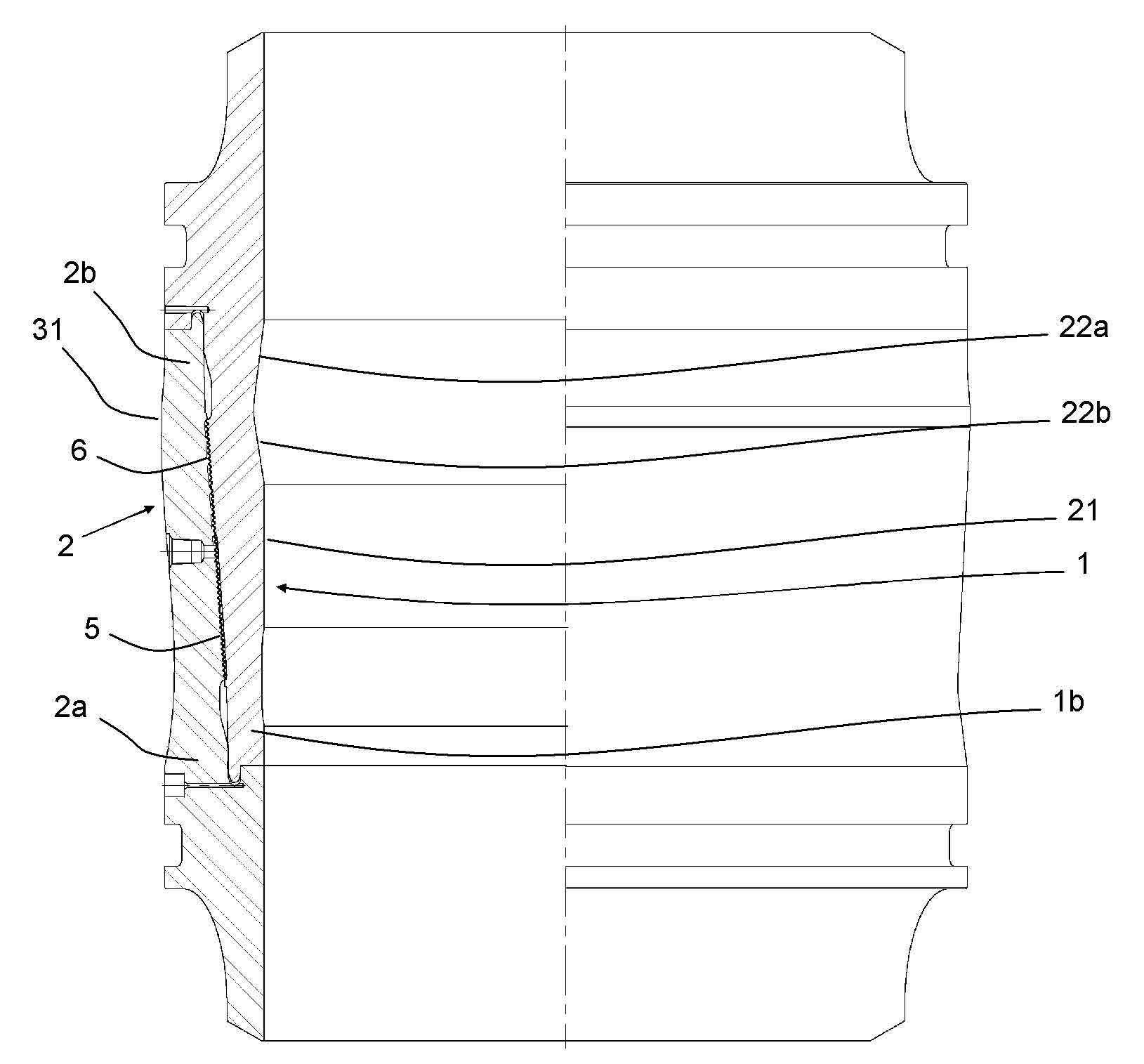

[0022] see first figure 1 and 2 , figure 1 and 2 A prior art pipe connector is shown comprising a tubular pin member 1 and a tubular box member 2 connected to Or it is connected to the ends of the two pipes, for example by welding. The pin member 1 and the box member 2 are designed to nest together, while both the outer surface 3 of the pin member 1 and the inner surface 4 of the box member 2 are generally frusto-conical and equipped with complementary protrusions. There are protrusions 5 and grooves 6 spaced axially along the length of the surface midway between the ends of the surface. The protrusions and grooves are relatively dimensioned so that when the pin and box members are fully engaged together, a corresponding one of the protrusions interengages in the groove to axially lock the two members together. The pin member 1 is described herein as having protrusions 5 and the box member 2 as having grooves 6, but it should be understood that these descriptions could be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com