Cement grinding aid and preparation method thereof

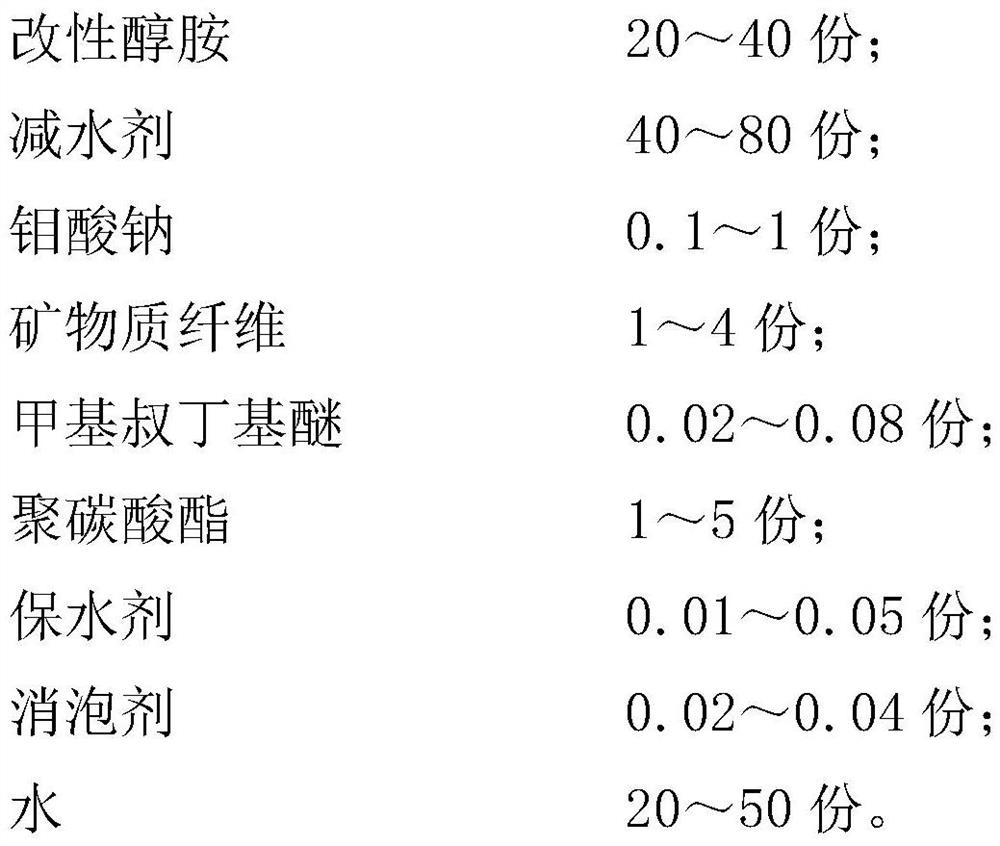

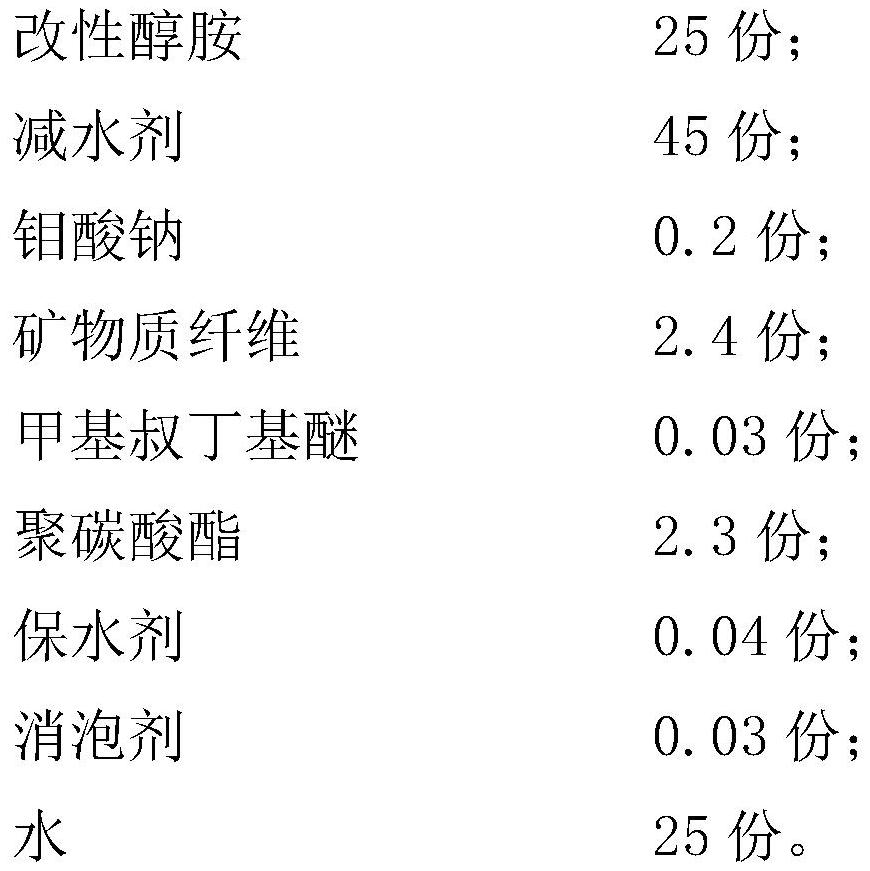

A cement grinding aid and water reducing agent technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc. The problem of high salt content of the agent can achieve the effect of significant spatial position effect, which is beneficial to flow and improves the strength of cement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

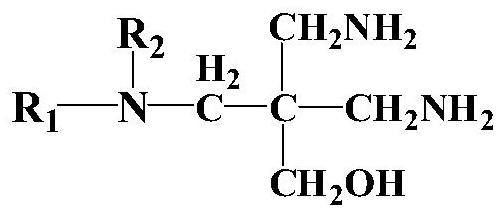

[0042]The invention also provides a method for preparing modified alcohol amine in cement grinding aids, which includes the following steps:

[0043]1) Preparation of 3,3-bis(chloromethyl)oxetane: react pentaerythritol and thionyl chloride in ice-water bath for 0.5~2h, overbased alumina column, purification to obtain 3,3-bis(chloro (Methyl) oxetane, the molar ratio of pentaerythritol to thionyl chloride is 1:1.01~1.05;

[0044]2) Preparation of modified alcohol amine: add the amine compound to 3,3-bis(chloromethyl)oxetane for 0.5~1h, add sodium azide and stir for 0.5~2h, after purification Add a reducing agent to perform a reduction reaction for 0.5 to 1h to obtain a modified alcohol amine. The molar ratio of the 3,3-bis(chloromethyl)oxetane, organic alcohol amine, sodium azide and the reducing agent is 1: 1.01~1.05: 2.01~2.1: 0.01~0.05.

[0045]The amine compound described in step 2) is one or a mixture of ammonia, ethanolamine, n-propanolamine, diethanolamine, diisopropanolamine, diglycola...

Embodiment 1

[0049]1) Preparation of 3,3-bis(chloromethyl)oxetane: react pentaerythritol and thionyl chloride in ice-water bath for 0.5~2h, overbased alumina column, purification to obtain 3,3-bis(chloro (Methyl) oxetane, the molar ratio of pentaerythritol to thionyl chloride is 1:1.01;

[0050]2) Preparation of modified alcohol amine: add the amine compound to 3,3-bis(chloromethyl)oxetane for 0.5~1h, add sodium azide and stir for 0.5~2h, after purification Add a reducing agent to perform a reduction reaction for 0.5 to 1h to obtain a modified alcohol amine. The molar ratio of the 3,3-bis(chloromethyl)oxetane, organic alcohol amine, sodium azide and the reducing agent is 1:1.01:2.01:0.01;

[0051]3) Combine 20 parts by weight of modified alcohol amine, 40 parts by weight of water reducing agent, 0.1 parts by weight of sodium molybdate, 1 part by weight of mineral fiber, 0.02 parts by weight of methyl tert-butyl ether, 1 part by weight The polycarbonate, 0.01 parts by weight of water retention agent, 0...

Embodiment 2

[0058]1) Preparation of 3,3-bis(chloromethyl)oxetane: react pentaerythritol and thionyl chloride in ice-water bath for 0.5~2h, overbased alumina column, purification to obtain 3,3-bis(chloro (Methyl) oxetane, the molar ratio of pentaerythritol to thionyl chloride is 1:1.05;

[0059]2) Preparation of modified alcohol amine: add the amine compound to 3,3-bis(chloromethyl)oxetane for 0.5~1h, add sodium azide and stir for 0.5~2h, after purification Add a reducing agent to perform a reduction reaction for 0.5 to 1h to obtain a modified alcohol amine. The molar ratio of the 3,3-bis(chloromethyl)oxetane, organic alcohol amine, sodium azide and the reducing agent is 1:1.05:2.1:0.05;

[0060]3) 40 parts by weight of modified alcohol amine, 80 parts by weight of water reducing agent, 1 part by weight of sodium molybdate, 4 parts by weight of mineral fiber, 0.08 parts by weight of methyl tert-butyl ether, 5 parts by weight The polycarbonate, 0.05 parts by weight of water-retaining agent, 0.04 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com