Method for the individual tracking of metallic hollow bodies

A technology of hollow body and metal, which is applied in the field of tracking metal hollow body alone, can solve the problems of design cost and achieve the effect of fast marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

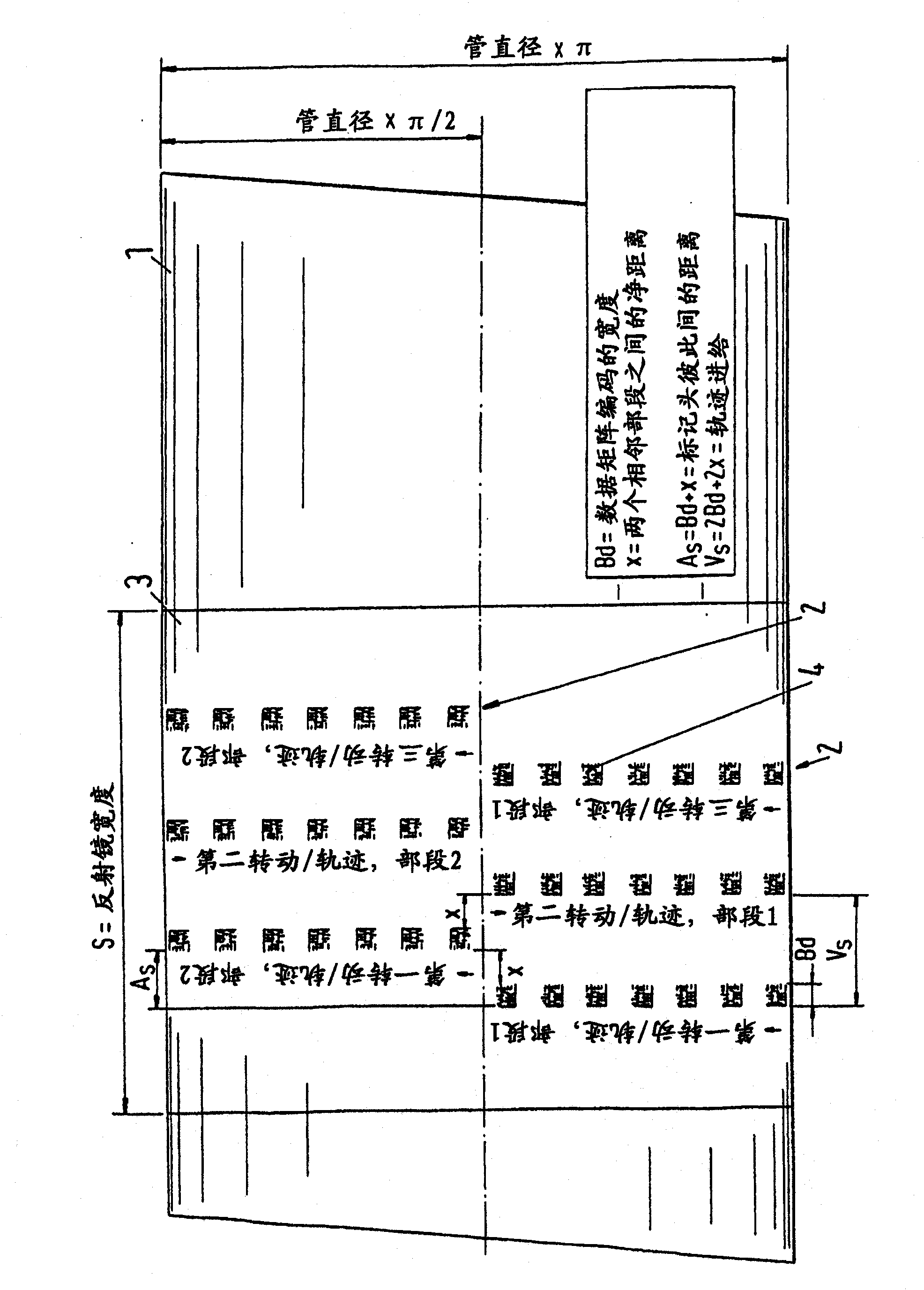

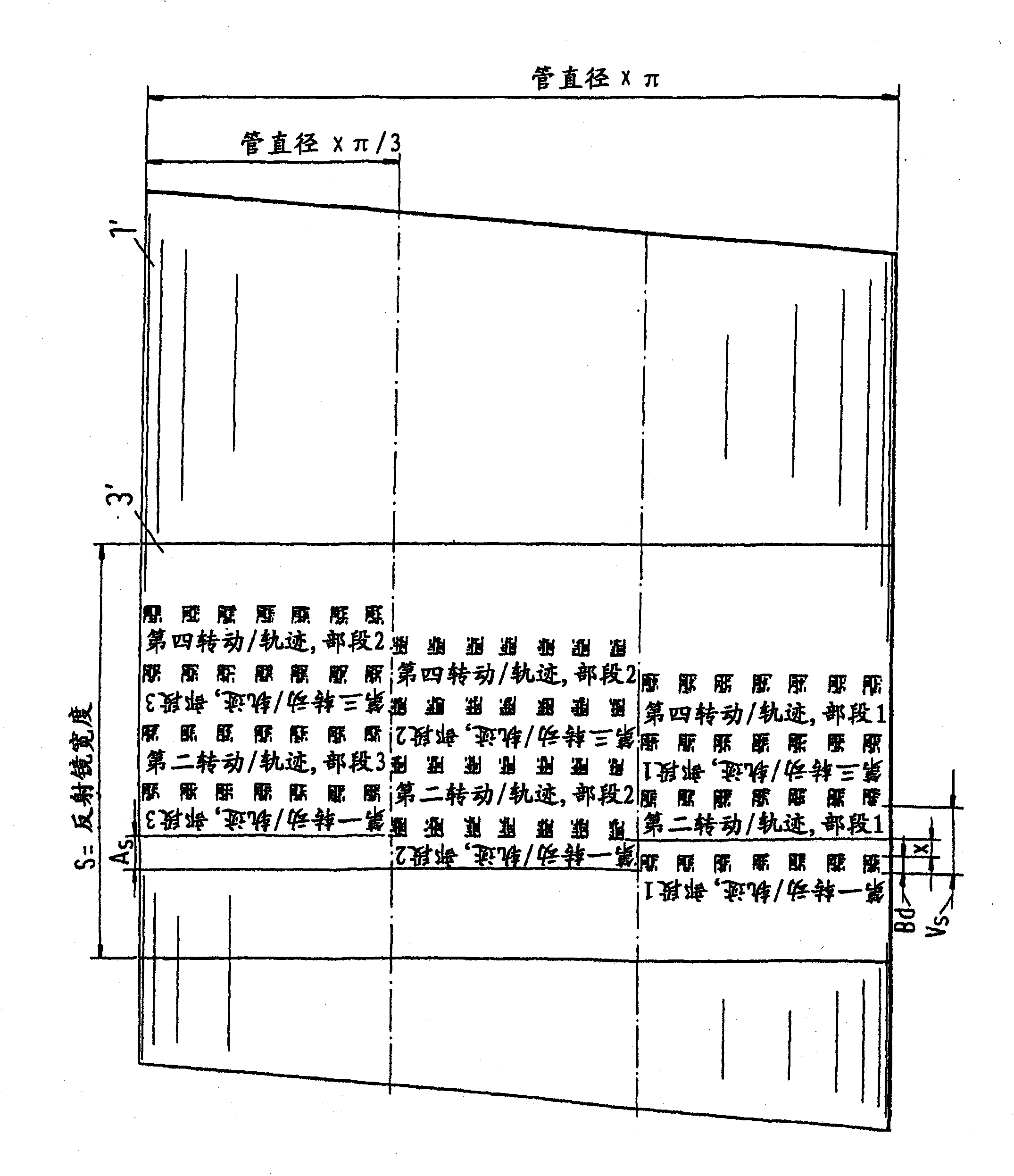

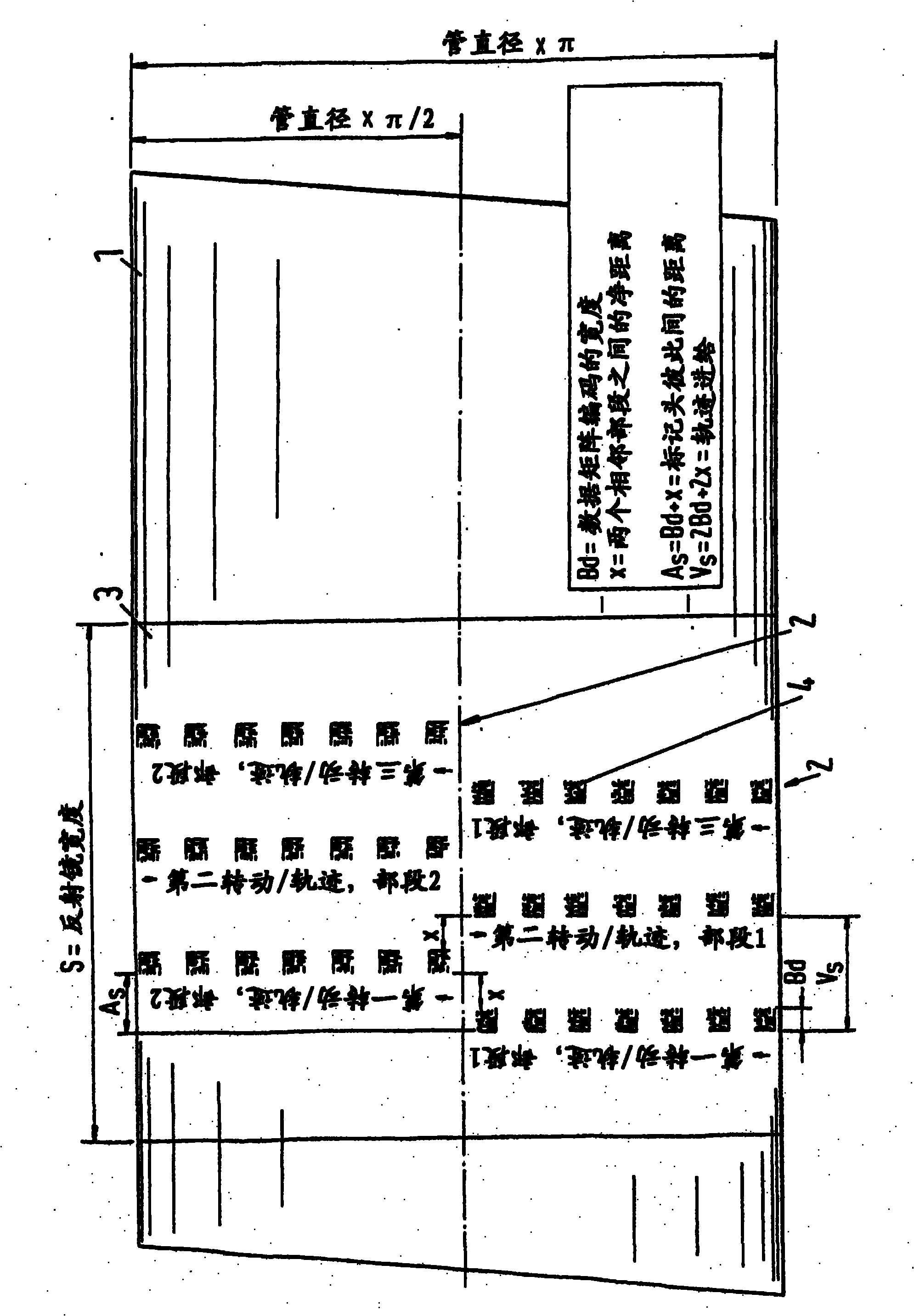

[0034] figure 1 A schematic diagram of the method according to the invention is shown, wherein the tube circumference is marked with two sections. Shown is an expanded view of the circumference of the tube 1 , wherein the tube circumference is marked with a data matrix code 4 by two axially offset segments 2 over a range of 180° in each case.

[0035] 1. Right click figure 1 Description of the first implementation form of the marking unit

[0036] In order to implement the method according to the invention according to figure 1 The marking unit used can be described as follows, where device features are not shown and can be modified according to enterprise requirements.

[0037] a. The tube 1 to be marked is stationary on the roller table.

[0038] b. A motor-driven rotating ring with a marking unit is provided around the pipe 1, the center of which is matched to the center of the pipe via a height adjustment device. Furthermore, the rotary ring can be moved along the tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com