Acidic milk powder and production method thereof

A milk powder, acid technology, applied in the field of acid milk powder and its production, can solve the problems of stability problem limitation, protein denaturation, inability to meet the requirements of taste diversity, etc., and achieve the effect of expanding the field of production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

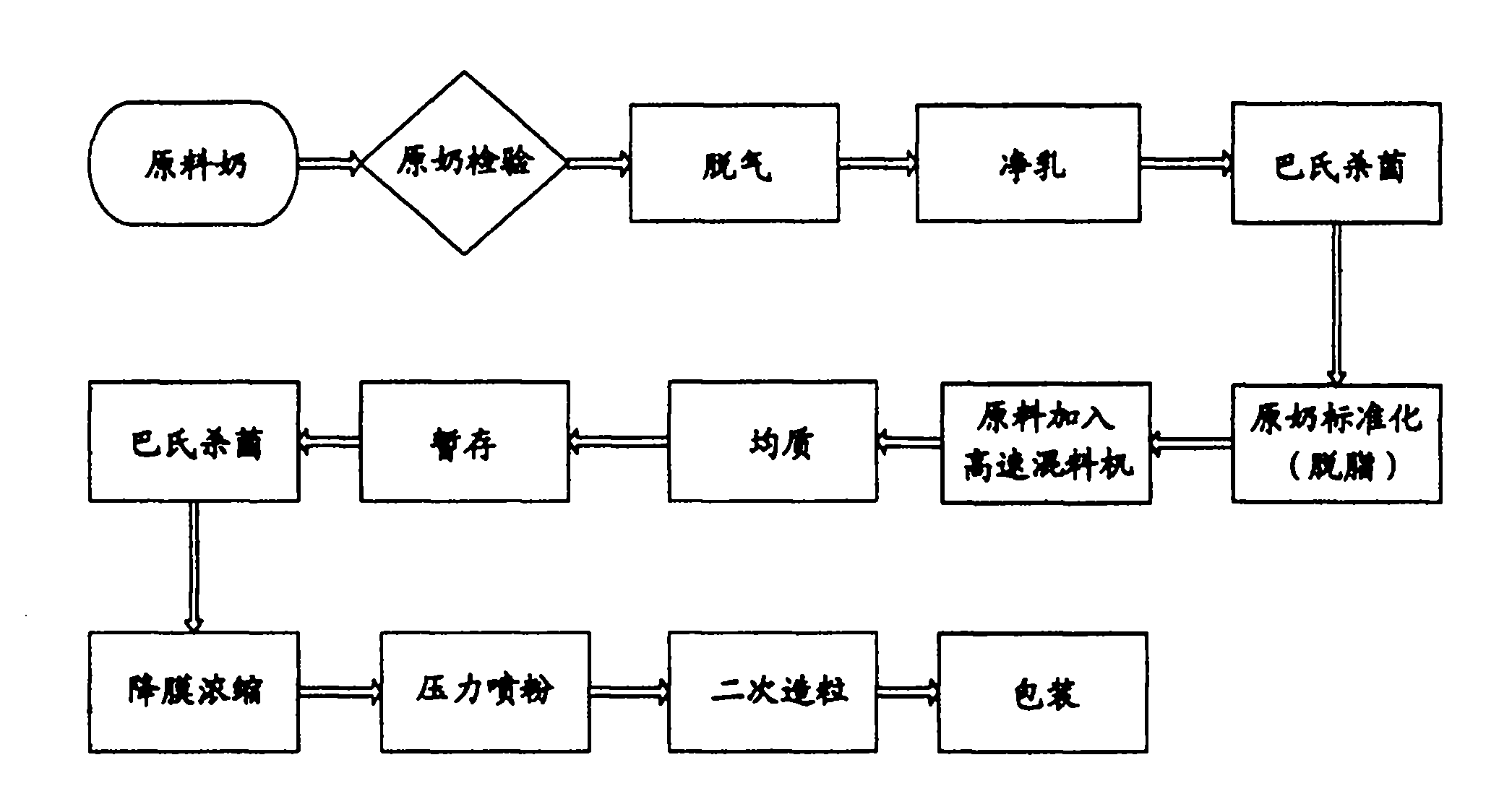

Method used

Image

Examples

Embodiment 1

[0123] In this embodiment, according to the method of the present invention, the raw material formula of Table 2 below is used to produce the product of the present invention.

[0124] Table 2

[0125]

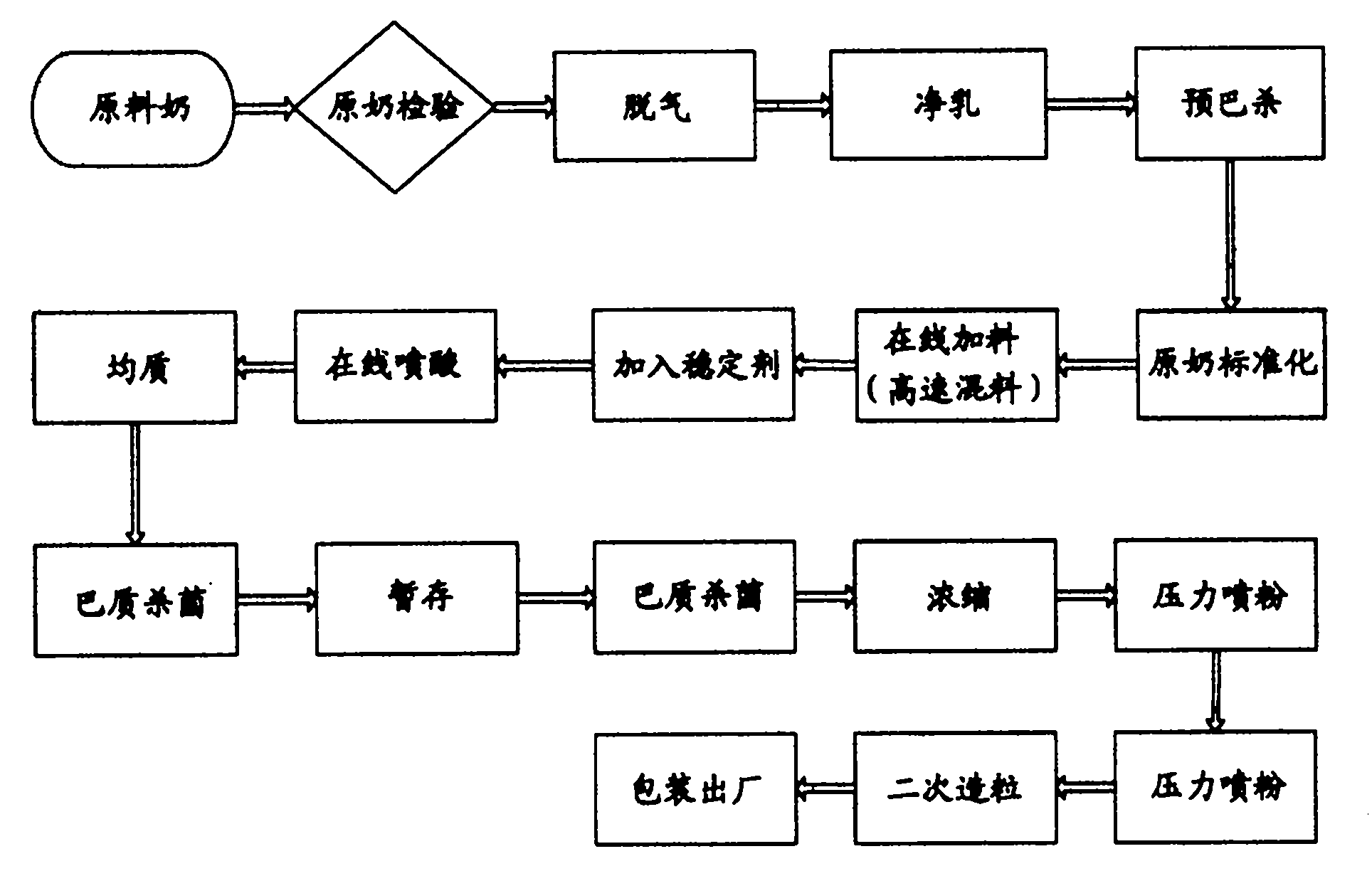

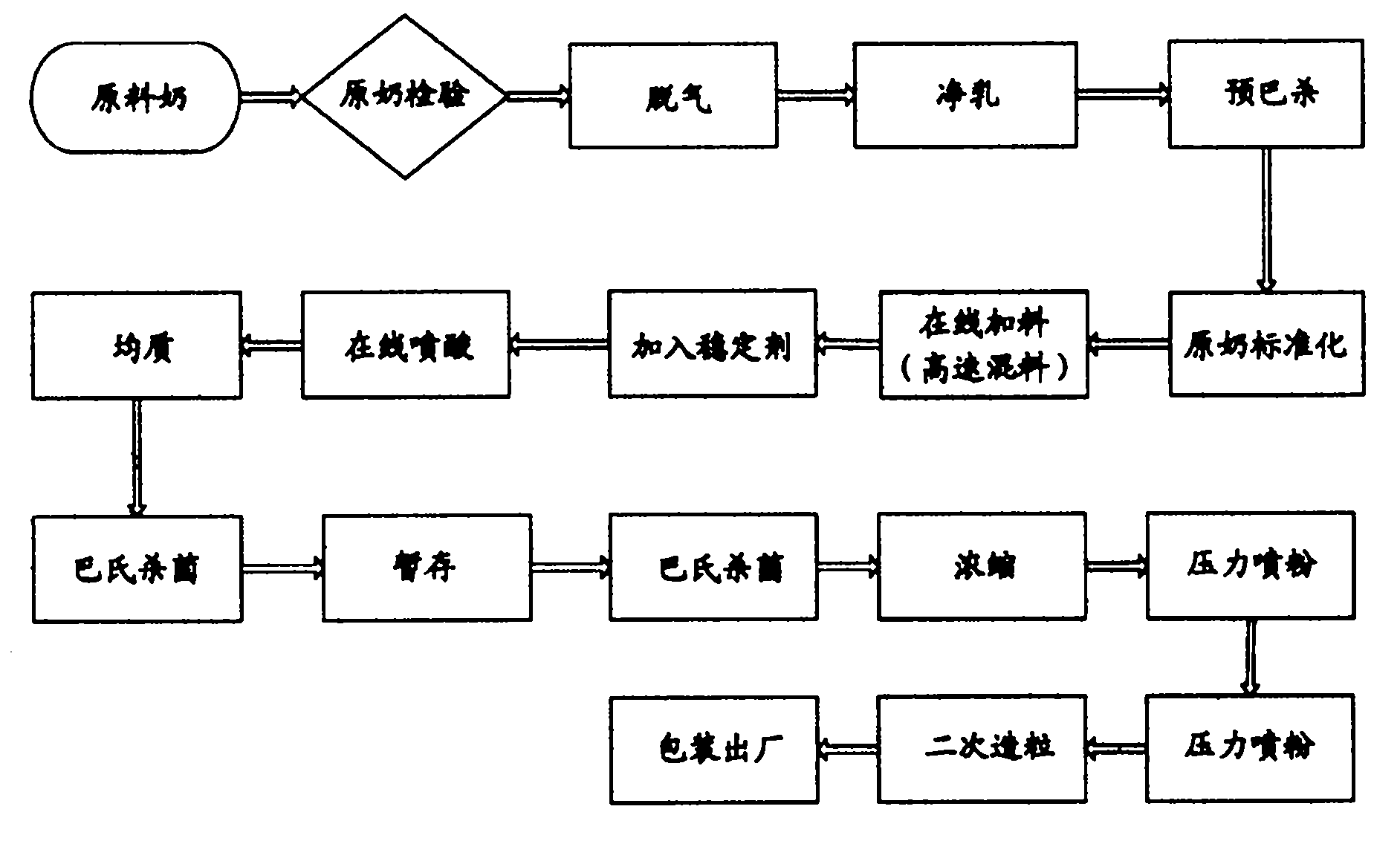

[0126] The specific production process is as follows: (see image 3 )

[0127] 1. Milk pretreatment process: After the milk is standardized, all the indicators are required to meet the production requirements. After standardization, the fat is 2.8% to 4.1%, and the protein is 2.65% to 3.45%. Raw milk requires refrigeration below 4°C. The specific requirements of the raw milk used are as follows:

[0128] a. Sensory indicators:

[0129] Color: uniform milky white or slightly yellowish.

[0130] Taste and smell: It has the inherent fragrance of fresh milk without other peculiar smell.

[0131] Tissue state: Uniform colloidal fluid, no precipitation, no clot, no impurities and other foreign bodies visible to the naked eye.

[0132] b. Physical and chemical indicators:

[0133] Relative densi...

Embodiment 2

[0175] In this embodiment, the raw material formula in Table 3 below is used to produce the product of the present invention. The production process is the same as in Example 1.

[0176] table 3

[0177]

Embodiment 3

[0179] In this embodiment, the raw material formula in Table 4 below is used to produce the product of the present invention. The production process is the same as in Example 1.

[0180] Table 4

[0181]

[0182] Benefit analysis

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com