Method for desulfurizing and denitrifying flue gas

A flue gas and denitrification technology, applied in the field of flue gas desulfurization and denitrification, can solve the problems of complex system, low sulfur removal efficiency, high equipment investment and operation and maintenance costs, and achieve good economic benefits and simple overall process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

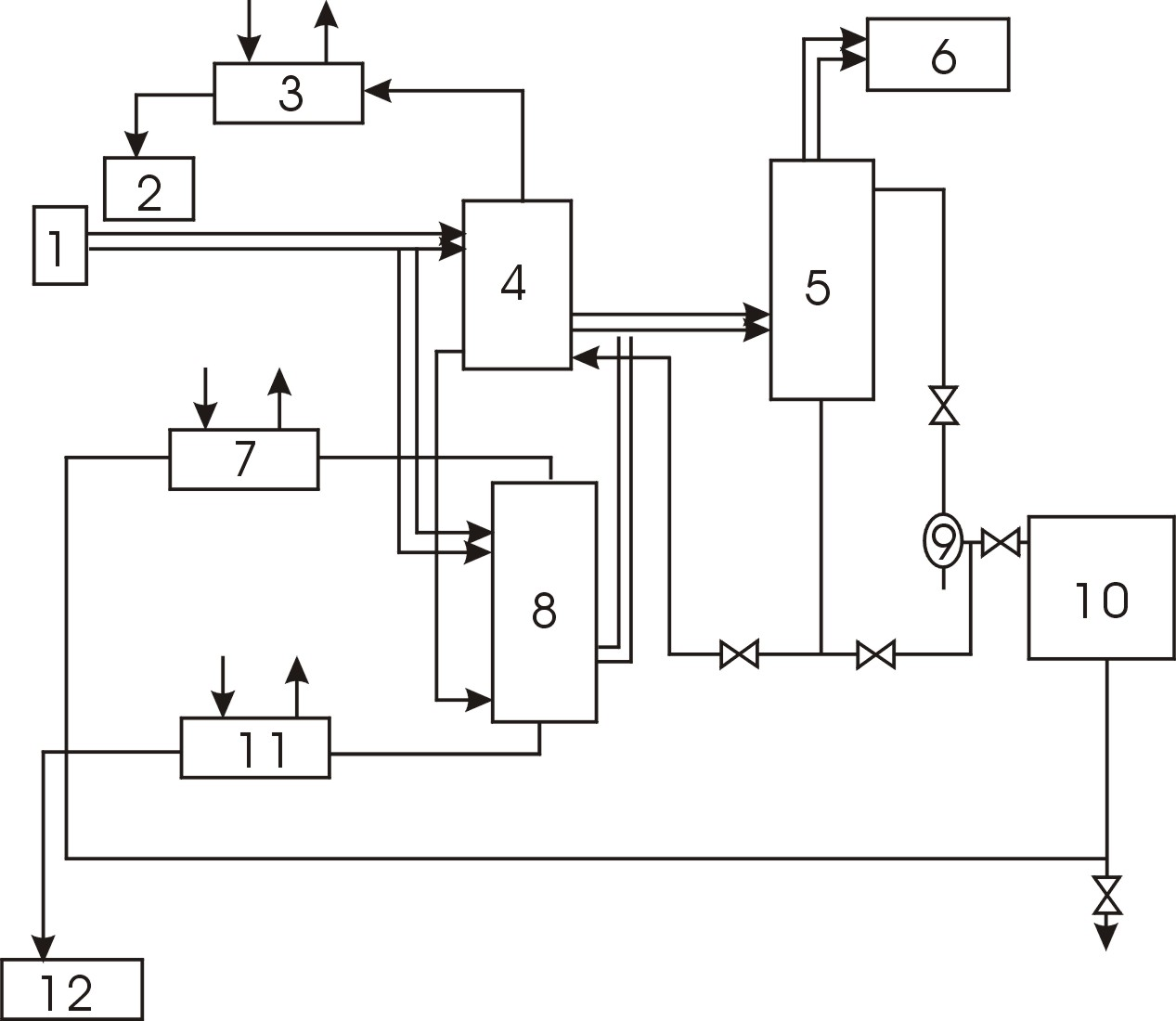

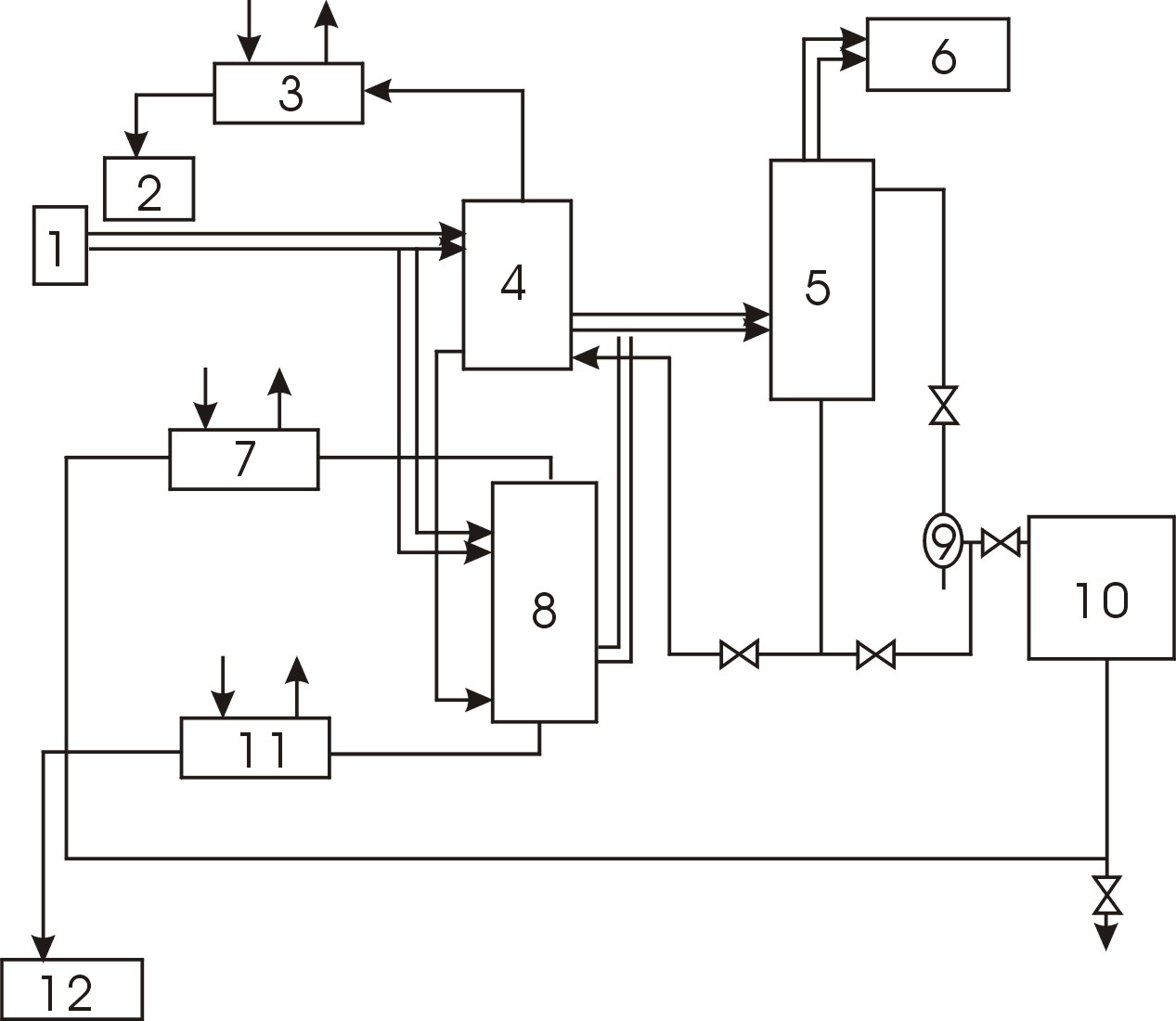

[0013] Now refer to the attached figure 1 , are described as follows in conjunction with the examples: a method for flue gas desulfurization and denitrification according to the present invention mainly utilizes H 2 o 2 Absorb SO in flue gas 2 , N X o X , use the temperature in the flue gas to heat and separate H 2 SO 4 and HNO 3 , including boiler flue 1, HNO 3 Storage tank 2, cooling device A3, heating separator A4, absorption tower 5, chimney 6, cooling device B7, heating separator B8, pump 9, H 2 o 2 Storage tank 10, cooling devices C11 and H 2 SO 4 Storage tank 12 is formed. The present invention adopts hydrogen peroxide to absorb SO in flue gas 2 and N X o X , can extract H 2 SO 4 and industrial HNO 3 , so that the flue gas reaches the emission standard, the reaction formula is:

[0014] SO 2 +H 2 o 2 ===H 2 SO 4

[0015] 2NO 2 +H 2 o 2 ===2HNO 3

[0016] 2NO 2 +3H 2 o 2 ===2HNO 3 +2H 2 o

[0017] N 2 O+4H 2 o 2 ===2HNO 3 +3H 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com