Preparation method for BOPP (biaxially-oriented polypropylene) film with high surface tension

A manufacturing method and high-surface technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of overload, damage to equipment, easy to burn out circuit boards, etc., to reduce power consumption and save energy , to avoid the effect of burning the circuit board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

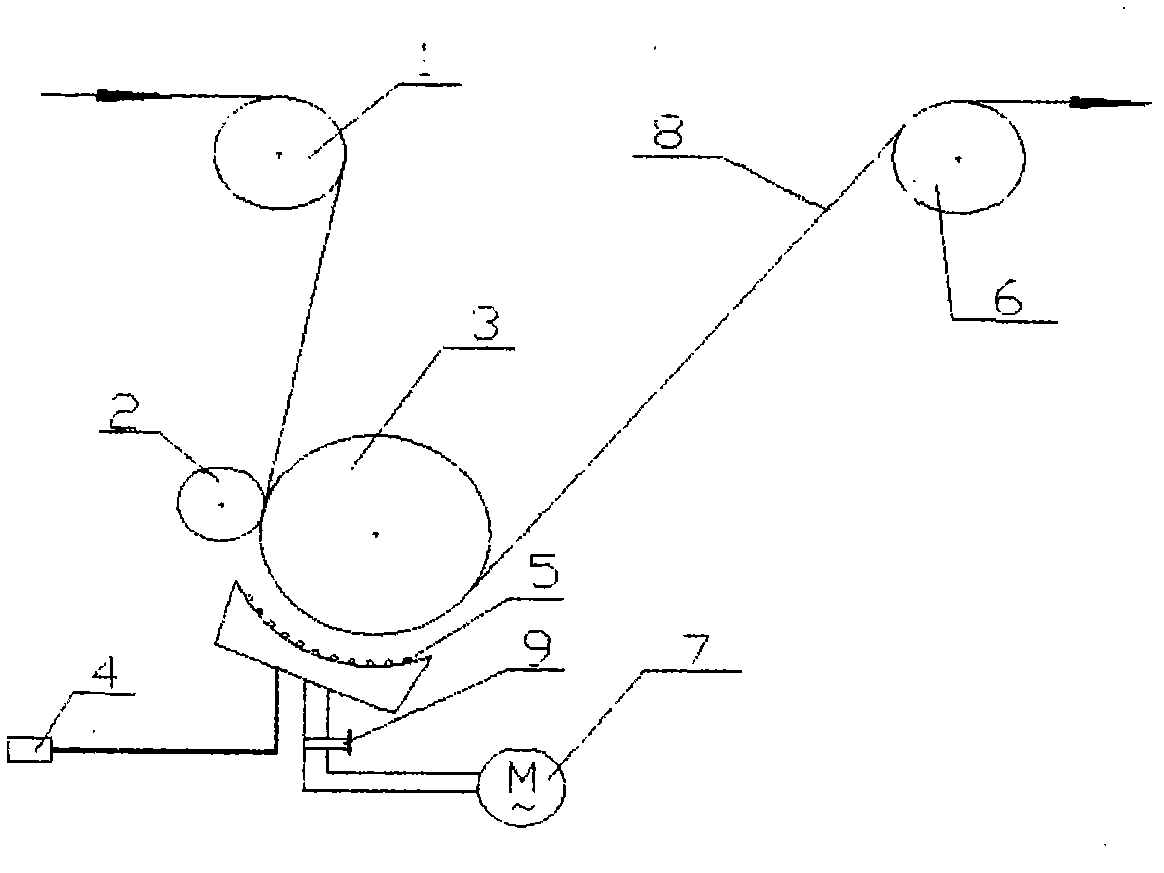

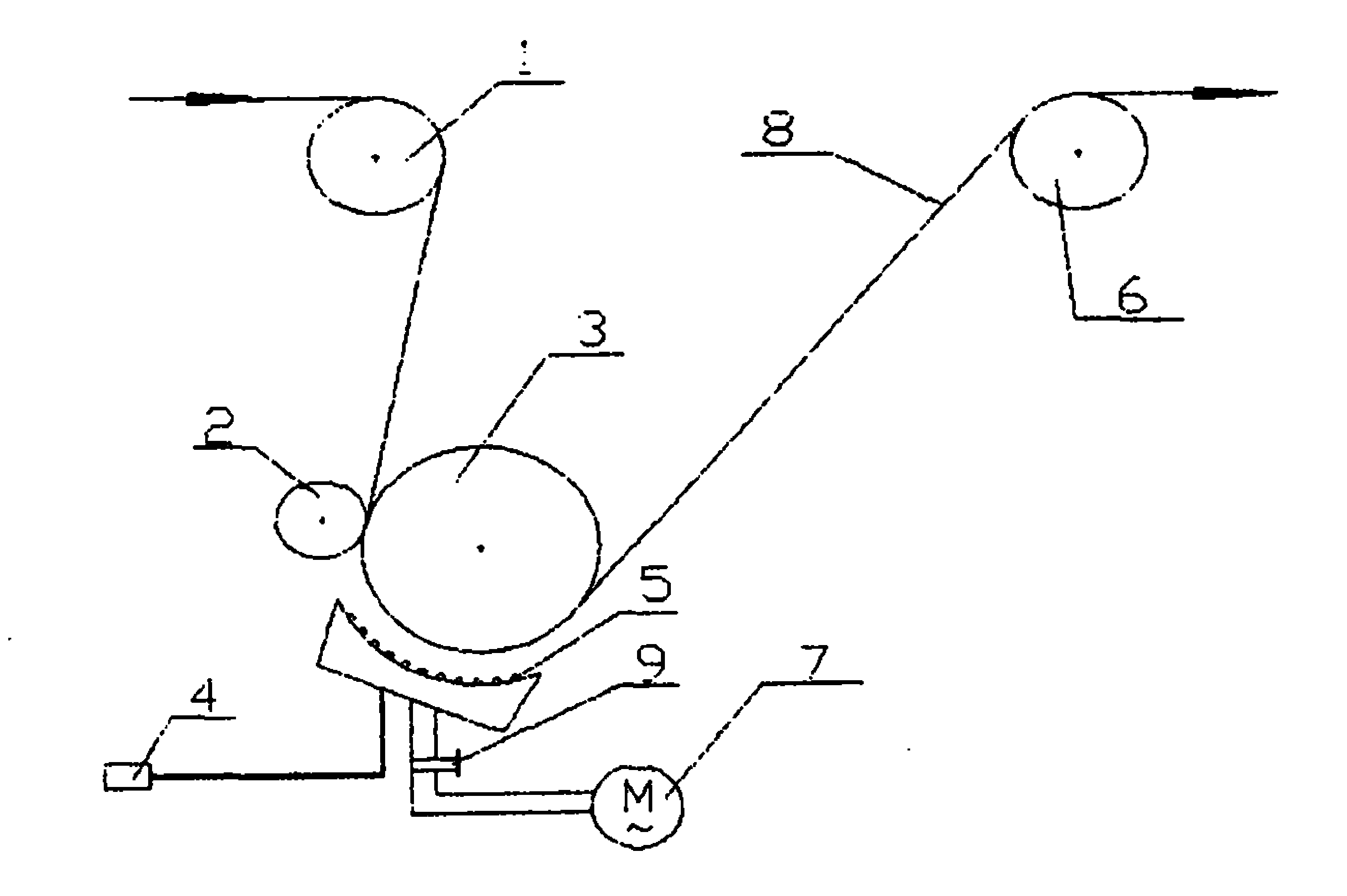

[0013] In order to solve the above-mentioned technical problems, the technical scheme of the present invention is: 1) improve the film temperature before processing, be beneficial to obtain equal surface tension under less processing power; 2) reduce the gap between electrode and film, also The above effects can be achieved; 3) increasing the ozone concentration in the treatment area also has the same effect. After the above multiple effects are superimposed, a significant improvement will be achieved. Finally, conventional processing power can be used to produce BOPP films with high surface tension, and the shelf life of products can be extended. At the same time, it also relieves the restriction of burning out the circuit board due to excessive power.

[0014] Such as figure 1 As shown, the BOPP film needs to pass through the chrome roller before treatment. The temperature of the chrome roller can be adjusted freely, and then it reaches the treatment area. At this position,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com