Shallow layer flotation machine for industrial wastewater treatment and treatment process thereof

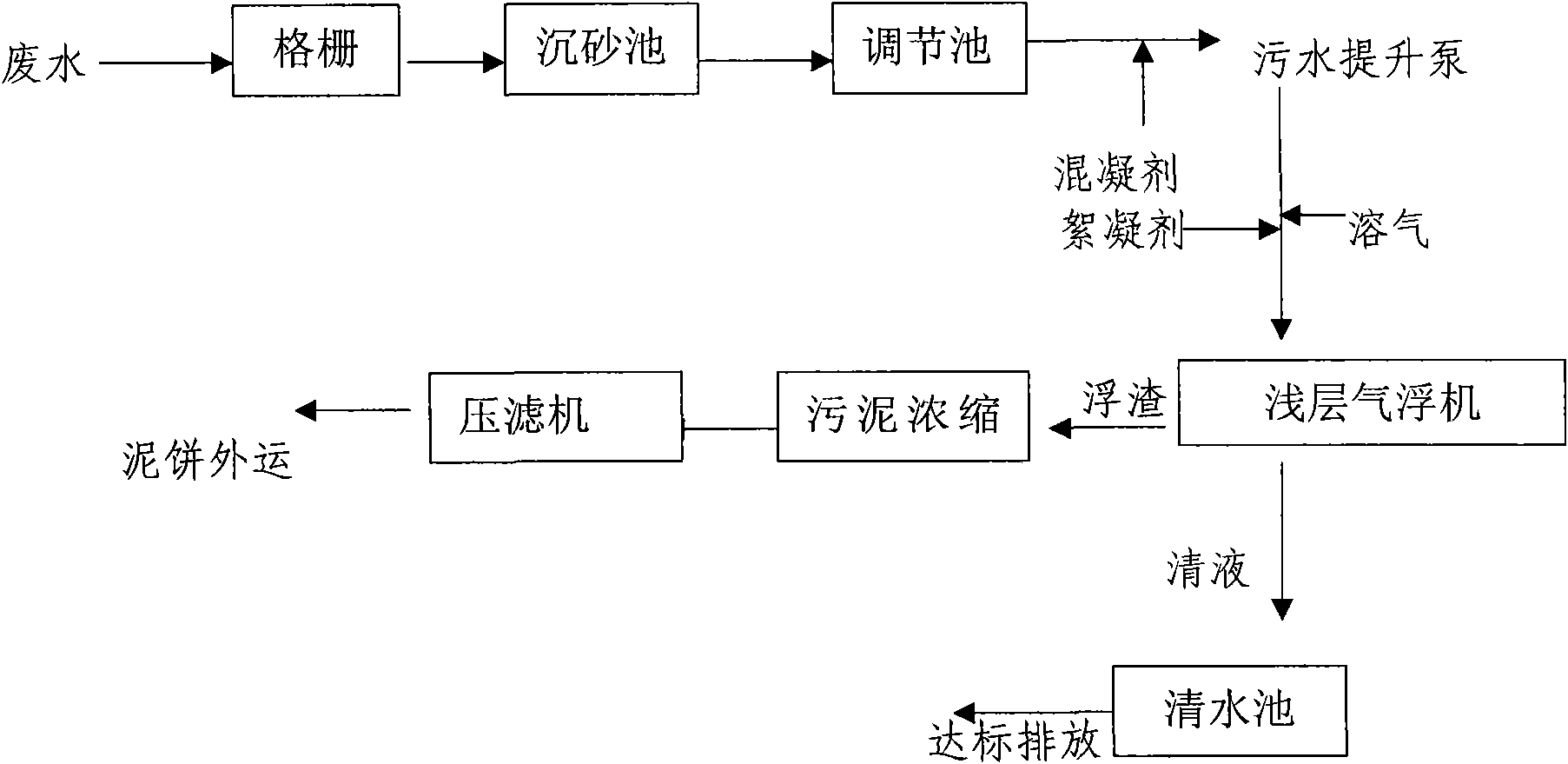

A technology for industrial wastewater and shallow air flotation, which is applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. Large volume and other problems, to achieve the effect of short residence time, high separation efficiency, and small tank volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

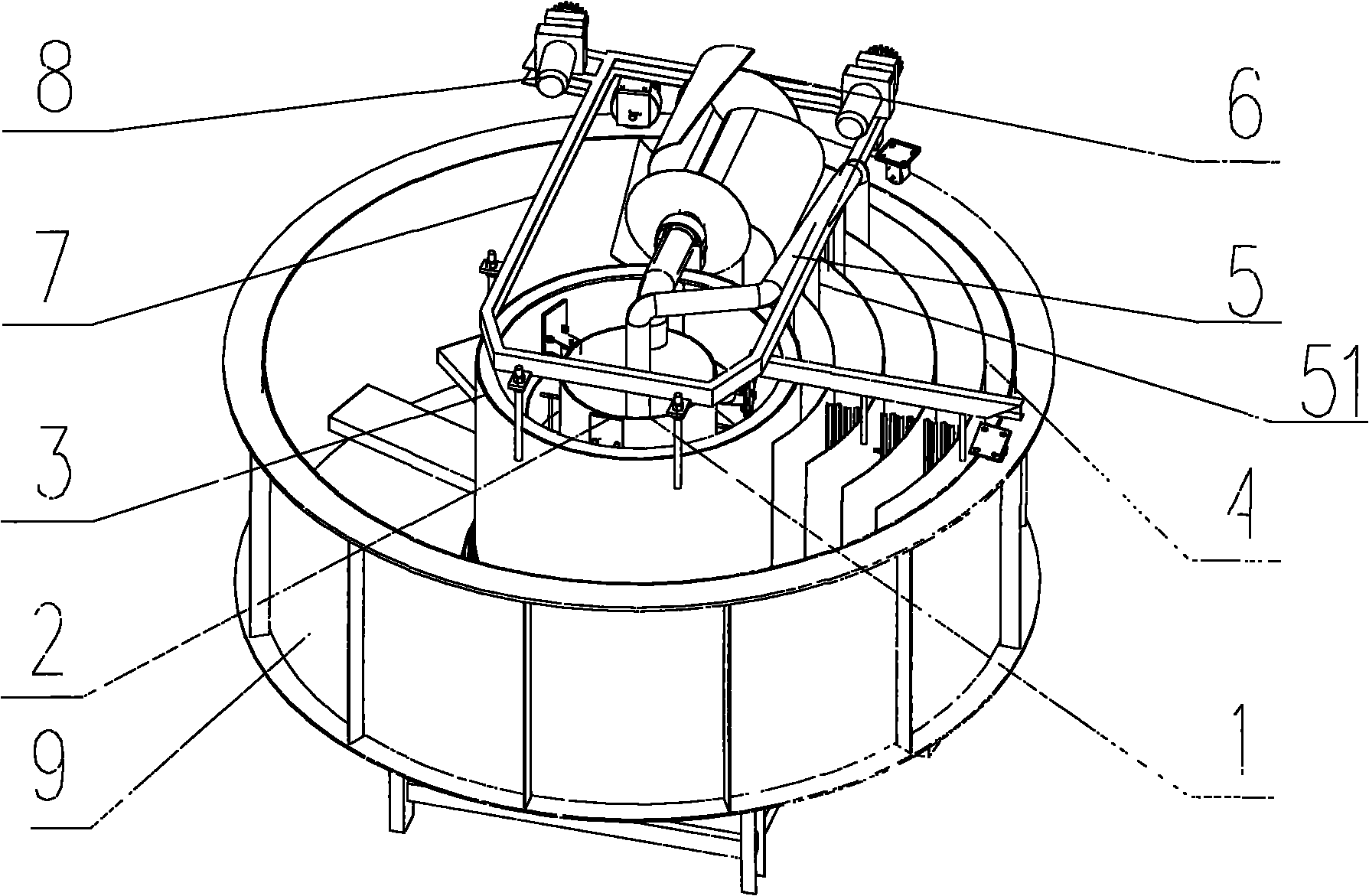

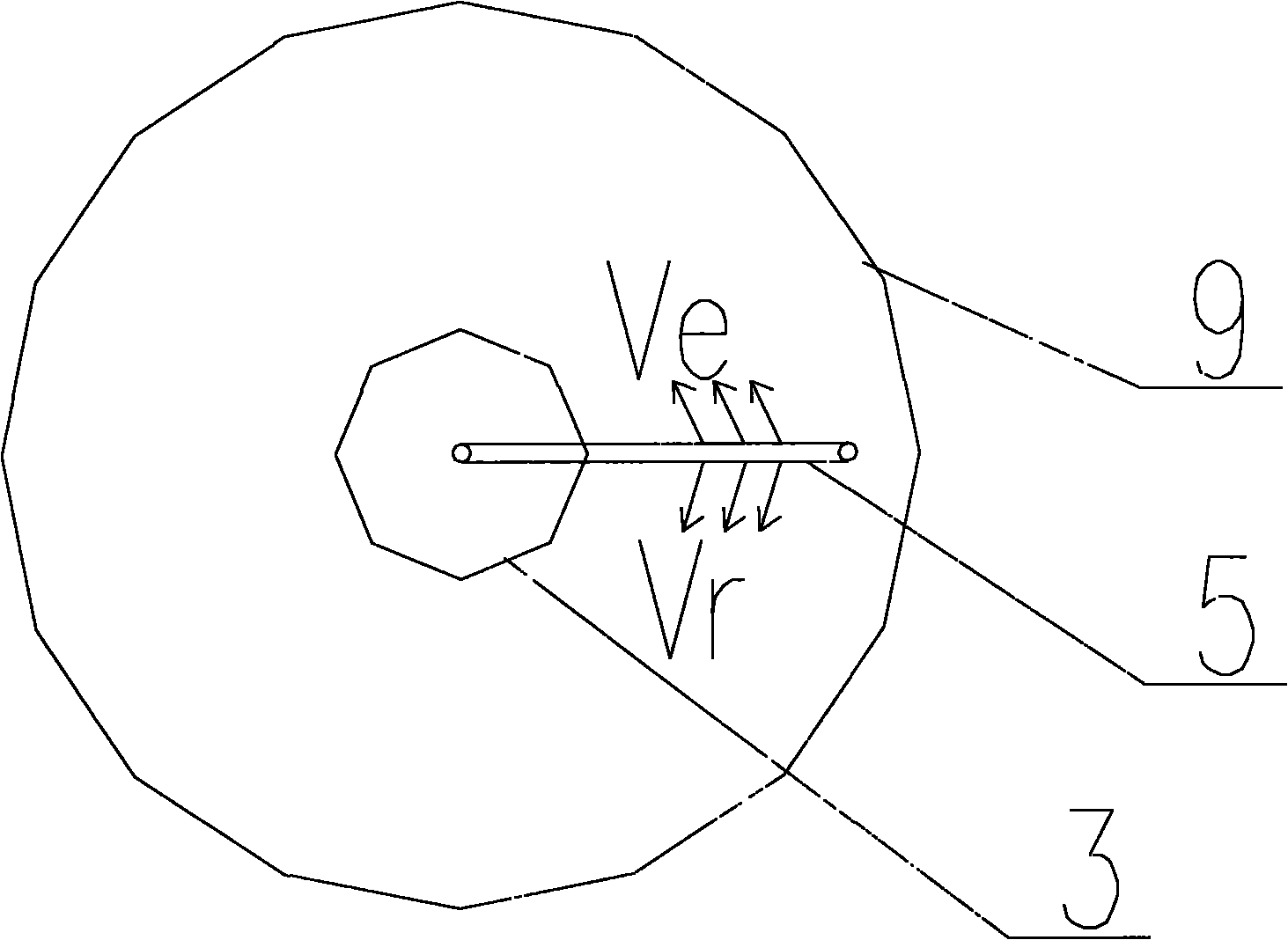

[0018] The structure diagram of the present invention is as figure 1 As shown, the shallow air flotation machine for industrial wastewater air flotation treatment of the present invention includes a slag discharge cylinder 1, a weir plate 2 capable of adjusting the water level, a rotating central cylinder 3, a water distribution partition 4, a rotating Water inlet main pipe 5, rotating water inlet branch pipe 51, rotating scum skimming device 6, center support 7, motor 8, air flotation machine cylinder 9, wherein the slag discharge cylinder 1 is located at the geometric center of the air flotation machine cylinder 9, and the rotating center cylinder 3 is placed on the outside of the slag discharge cylinder 1, the weir plate 2 capable of adjusting the water level is placed between the slag discharge cylinder 1 and the rotating central cylinder 3, and the water distribution partition 4 is installed between the rotating central cylinder 3 and the air flotation machine Between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com