Gasifier slag gravity and magnetic joint sorting process

A gasification slag and sorting technology, which is applied in the field of resource utilization of coal gasification ash, can solve problems such as unsatisfactory flotation effect, and achieve the effect of low production cost and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

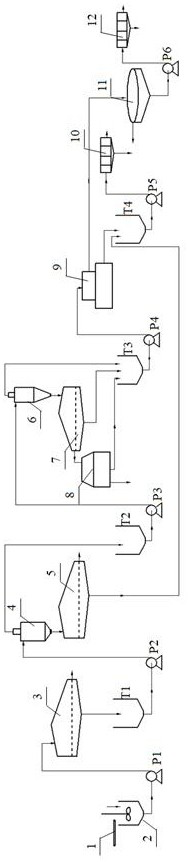

[0034] 1. The gasification slag enters the slurry preparation tank 2 through the belt conveyor 1, and a certain quality of water and coal gasification slag are added to make a slurry with a mass concentration of 70g / L after fully stirring, and the coal gasification slag is fully dispersed in the slurry preparation tank 2 .

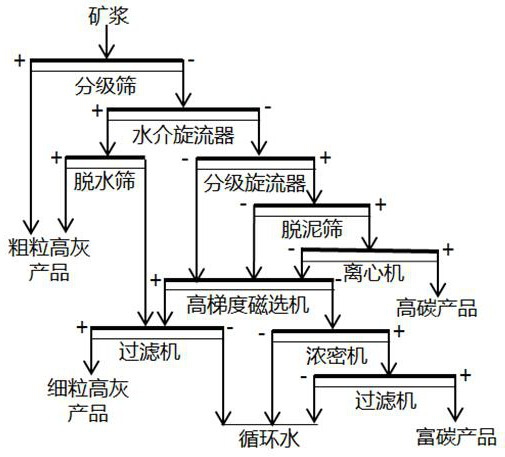

[0035] 2. The gasified slag slurry is pumped into the grading screen 3 by the delivery pump P1 to remove particles and impurities larger than 3mm. After dehydration, the particles and impurities on the screen are directly treated as coarse-grained and high-ash products.

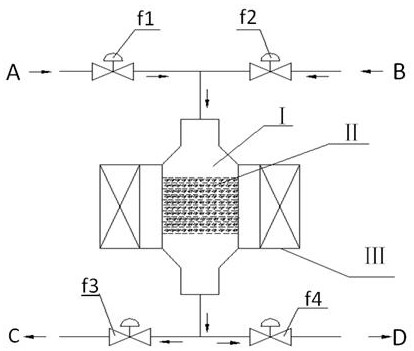

[0036] 3. The slurry under the screen passes through the slurry buffer tank T1 and is driven by the delivery pump P2 into the coal slime cyclone gravity separation column 4 with a diameter of 150mm for separation. The feeding pressure is 0.15Mpa. The barrel T2 is pumped into the classifying cyclone 6 with a diameter of 200mm by the delivery pump P3 for classification, the feeding pressure...

Embodiment 2

[0042] 1. The gasification slag enters the slurry preparation tank 2 through the belt conveyor 1, and a certain quality of water and coal gasification slag are added to make a slurry with a mass concentration of 70g / L after fully stirring, and the coal gasification slag is fully dispersed in the slurry preparation tank 2 .

[0043] 2. The gasified slag slurry is pumped into the trommel classifying sieve 3 by the conveying pump P1 to remove particles and impurities above 3 mm, and the particles and impurities on the sieve are dehydrated and directly treated as coarse-grained and high-ash products.

[0044]3. The pulp under the screen passes through the pulp buffer tank T1 and is driven by the delivery pump P2 into the hydrocyclone 4 with a diameter of 150mm and a large cone angle for separation. The cone angle is 90°, the feeding pressure is 0.2Mpa, and the hydrocyclone with a large cone angle The overflow of device 4 passes through the slurry buffer tank T2 and is pumped into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com