Alcohol distillation process

A process and alcohol technology, applied in the field of alcohol distillation process, can solve the problems of poor environmental protection economic benefits, large gaps and high energy consumption, and achieve the effects of reducing comprehensive energy consumption, saving steam required for heating, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

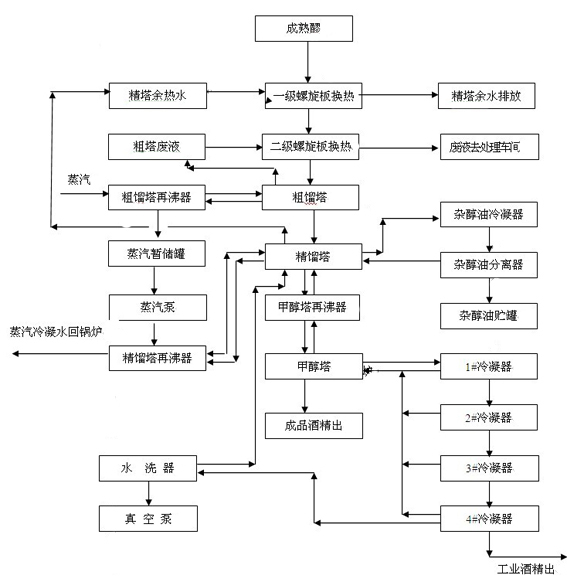

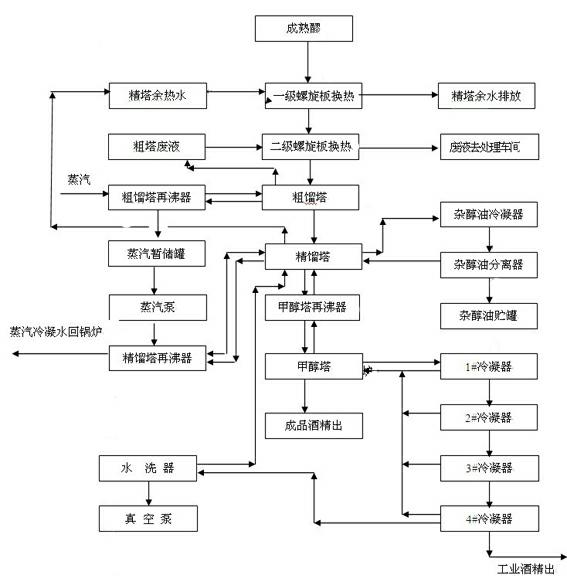

[0012] Such as figure 1 Shown, a kind of alcohol distillation process of the present invention, it is to adopt the full negative pressure rectification technology that reduces the operating pressure and temperature of distillation system, multiple volatile and non-volatile substances in the alcohol fermentation mature mash are passed through thick tower, fine tower, Methanol column for separation. Its specific process steps are as follows:

[0013] First of all, the fermented mature mash from the fermentation section is heated to 40°C-55°C in the first stage through a spiral plate heat exchanger (the waste water is discharged from the refining tower), and the fermented mature mash with a temperature of 40°C-55°C enters the second stage. The secondary spiral plate heat exchanger (using the waste liquid discharged from the crude tower) is reheated to 60°C-75°C, and the fermented and mature mash is sent to the crude distillation tower for distillation at a temperature of 60°C-75...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com