Composite floating ball

A composite, floating ball technology, applied in the direction of the float of the control valve, solar thermal power generation, valve details, etc., can solve the problems of high manufacturing cost, insufficient buoyancy of the ball, affecting design requirements, etc., and achieve long service life, reasonable process, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

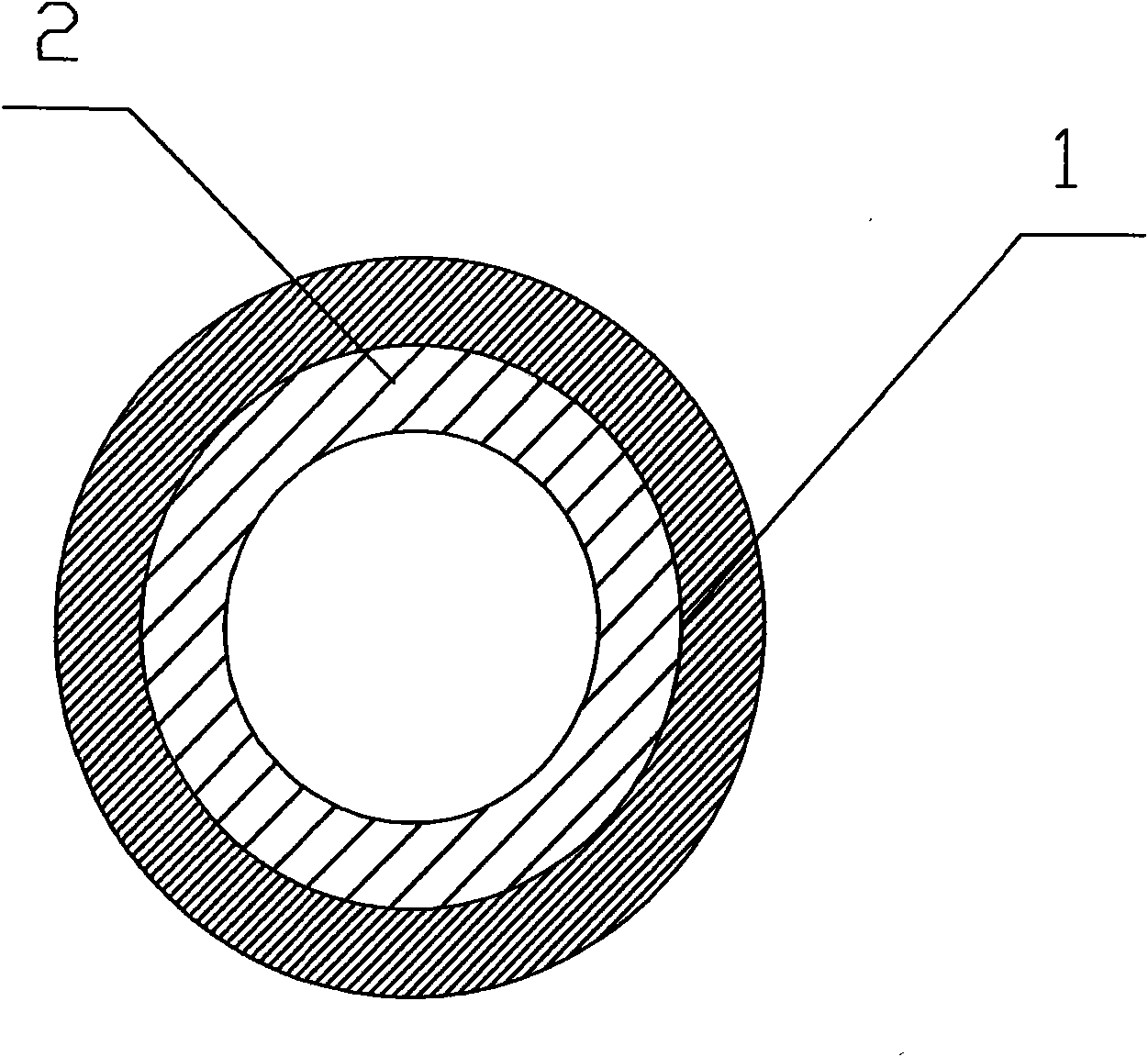

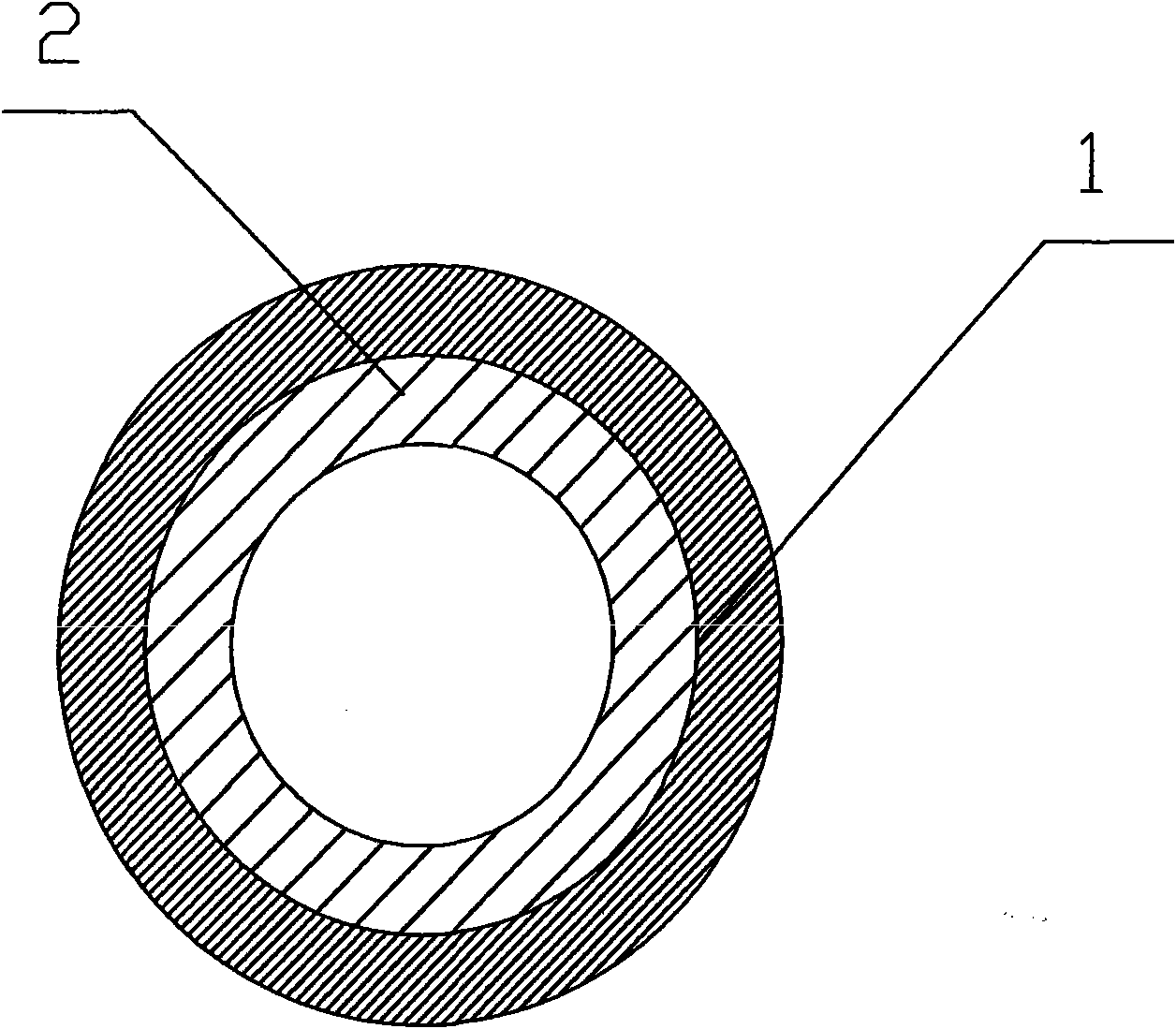

[0013] Such as figure 1 The object of the present invention is to provide an embodiment of a composite floating ball, the floating ball is divided into an inner ball 2 and an outer ball 1 .

[0014] Its inner ball 2 is a hollow ball made of non-metallic or metal material with high temperature resistance, high pressure resistance and high density, which can float in the liquid.

[0015] The outer ball 1 is compounded by injecting organic materials into the inner ball 2 through injection molding, molding and extrusion processes to ensure the appearance shape and quality of the ball, and to be able to float in the liquid.

[0016] Its advantage is that the high-performance material with high temperature resistance, high pressure resistance and high density is used as the hollow ball, so that the product is not easy to generate condensation and damage in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com