Polycrystalline light-emitting diode packaging structure for generating similar round light-emitting effect

A technology of light-emitting diodes and light-emitting effects, which is applied to electrical components, electrical solid-state devices, circuits, etc., to achieve the effects of long service life, stable voltage and stable current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

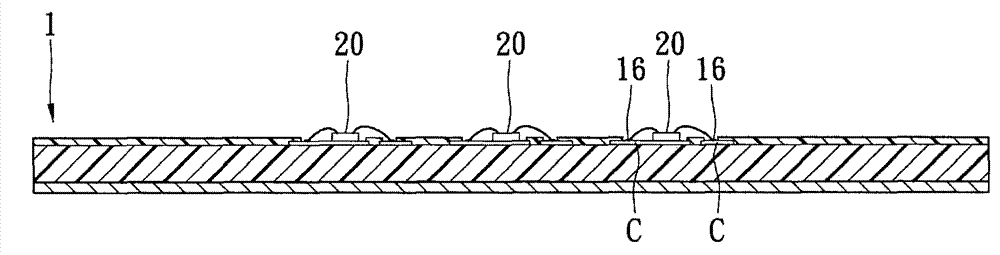

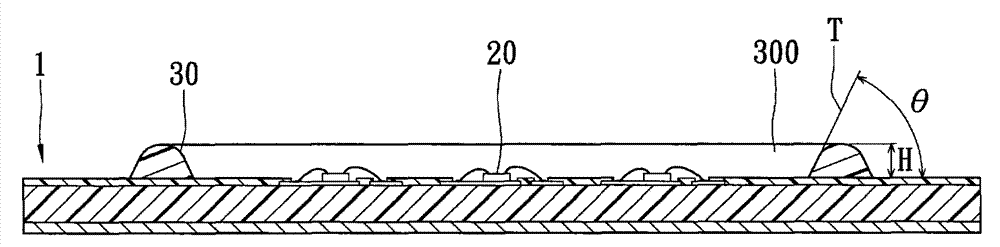

[0058] see Figure 1A to Figure 1D As shown, the following is a detailed description (steps S100 to S108) of the manufacturing method of the "multi-chip light-emitting diode package structure P for producing a circular light-emitting effect" exemplified in the first embodiment of the present invention:

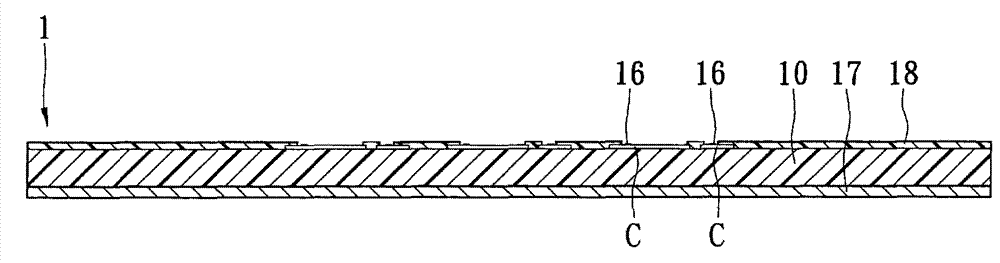

[0059] Please refer to Figure 1A As shown, first, a substrate unit 1 is provided, which has a substrate body 10, a plurality of conductive lines C arranged on the upper surface of the substrate body 10, a plurality of conductive pads 16 arranged on the upper surface of the conductive lines C, A heat dissipation layer 17 disposed on the bottom of the substrate body 10 , and an insulating layer 18 disposed on the upper surface of the substrate body 10 and used to cover part of the conductive lines C to expose the conductive pads 16 (step S100 ). Therefore, the heat dissipation layer 17 can be used to increase the heat dissipation performance of the substrate unit 1, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com