Electrode for polymer electrolyte membrane fuel cell and method for forming membrane-electrode assembly using the same

A technology for electrolyte membranes and fuel cells, applied in solid electrolyte fuel cells, fuel cell components, battery electrodes, etc., can solve problems such as reducing hydrogen ion conductivity and reducing fuel cell performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3

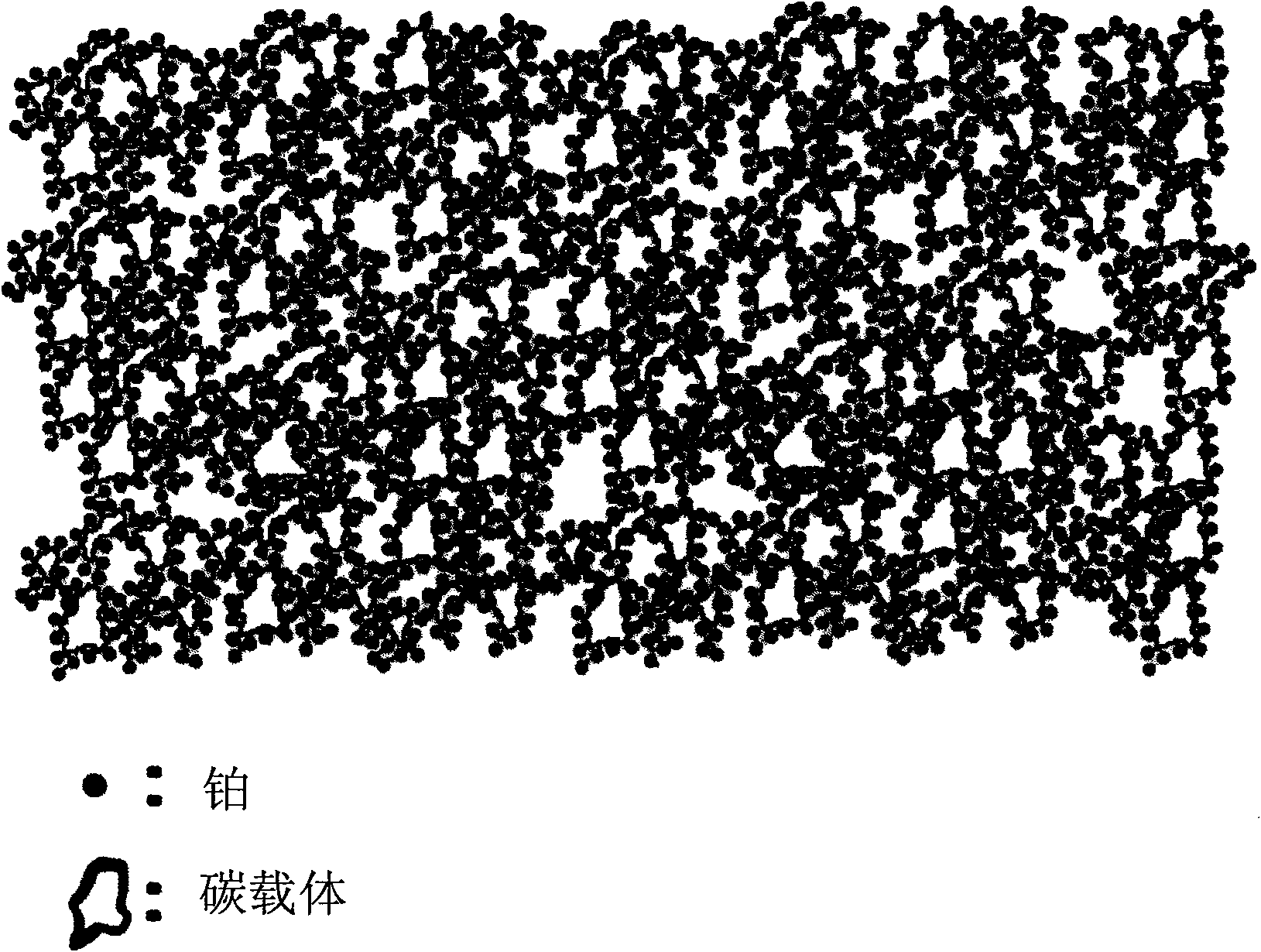

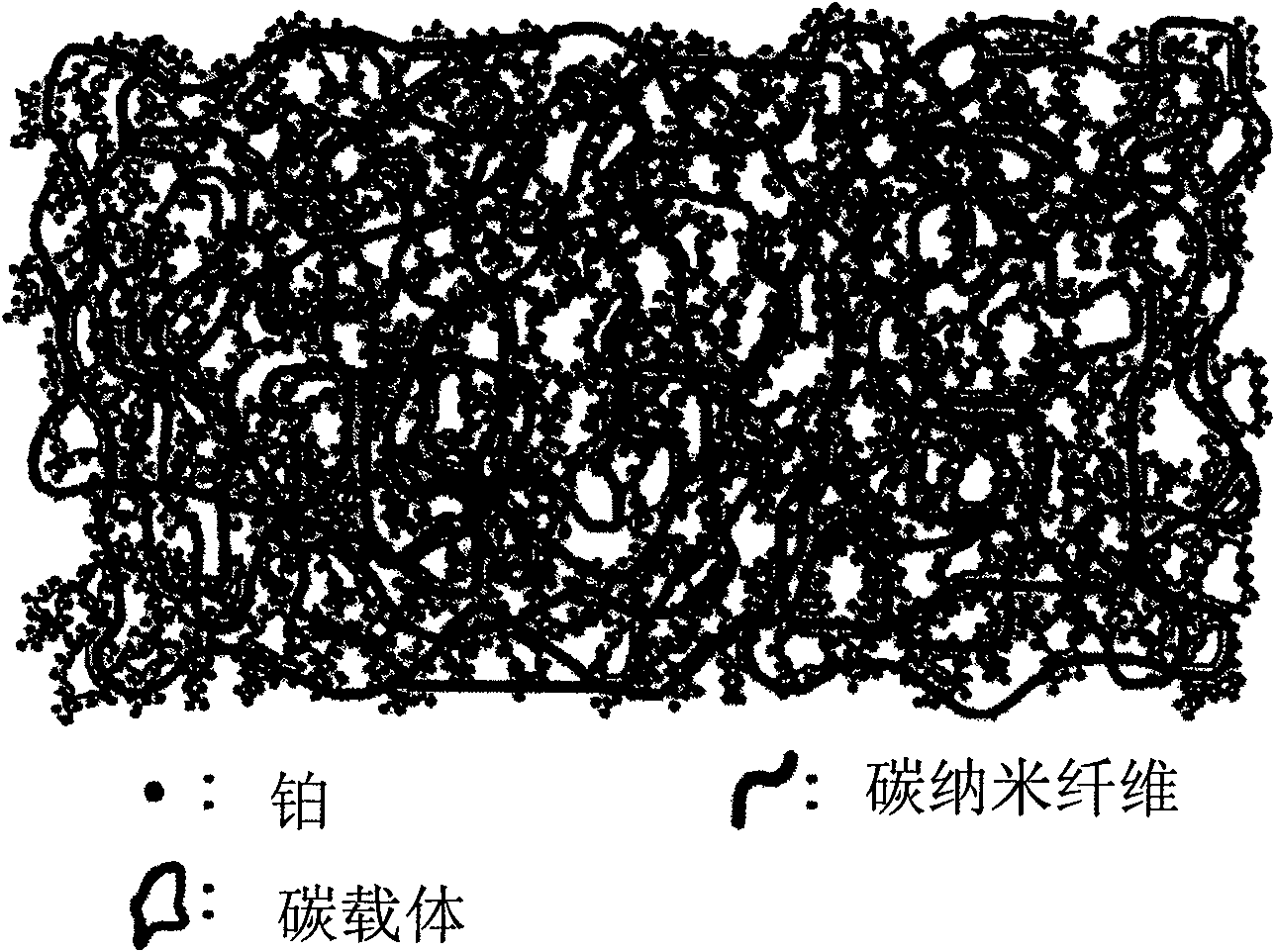

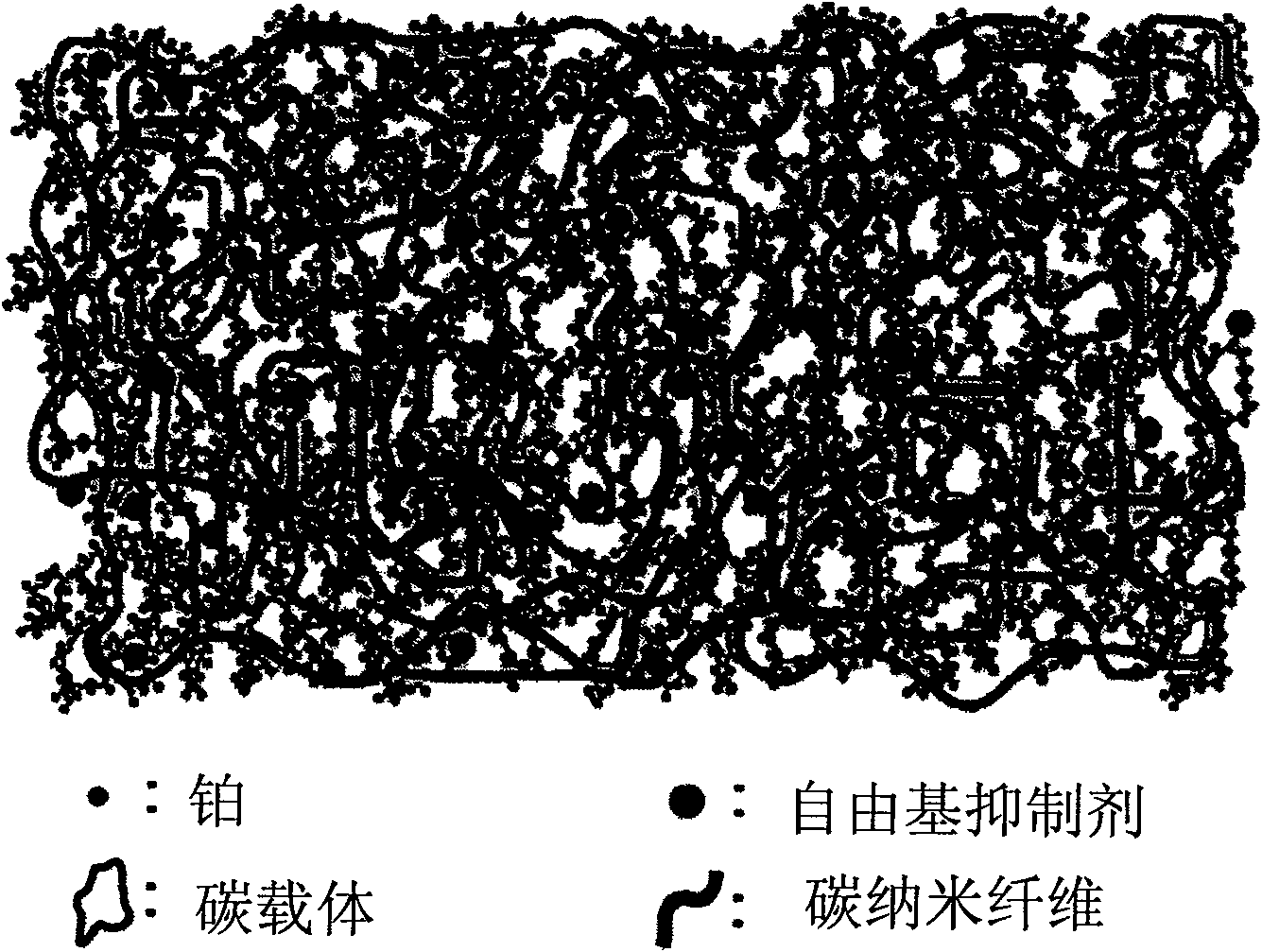

[0093] In the first exemplary embodiment, in Example 1, by mixing 4 parts by weight of carbon nanotubes as one of the carbon nanofibers with a solvent relative to 100 parts by weight of the catalyst (6 parts by weight were used in Example 2 Parts of carbon nanotubes, 8 parts by weight of carbon nanotubes were used in Example 3), and 10 parts by weight of cerium-zirconium oxide as a free radical inhibitor was added to the mixture to prepare a catalyst slurry. The prepared catalyst slurry was properly coated on release paper and dried, and the dried electrode was hot-pressed onto the polymer membrane, thereby forming the membrane electrode assembly of each embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com