Battery cooling system

A battery and low-temperature technology, applied in secondary batteries, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

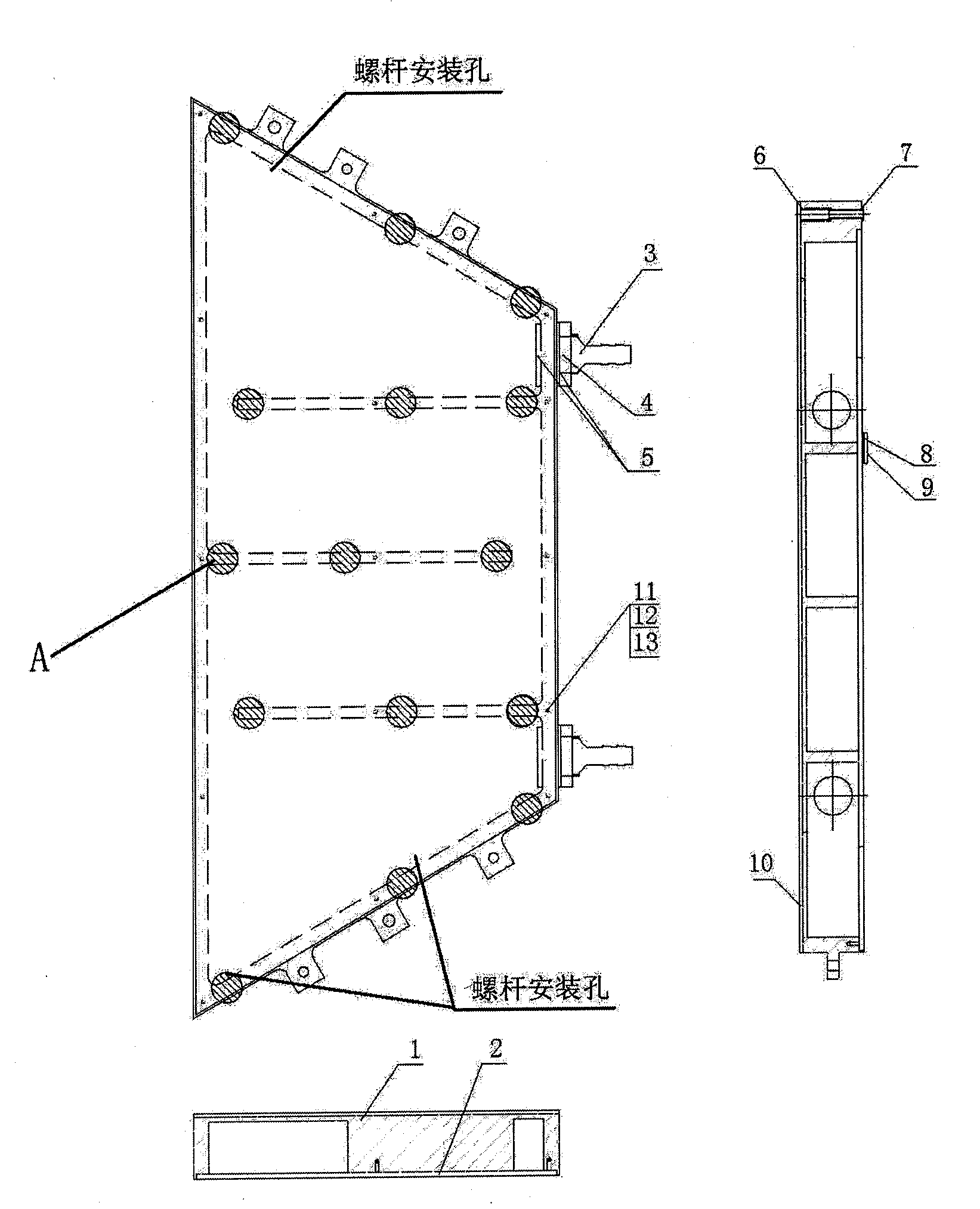

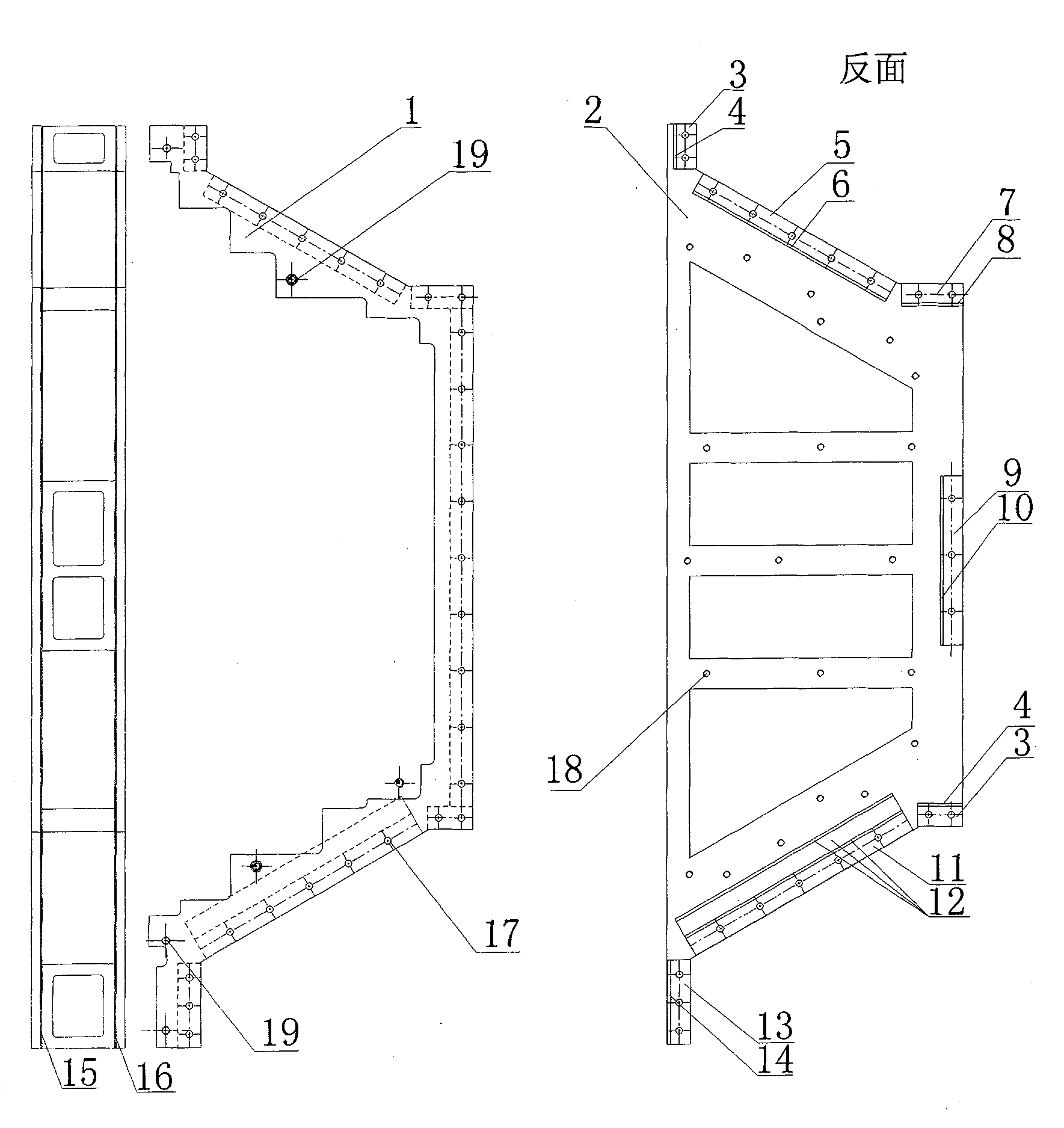

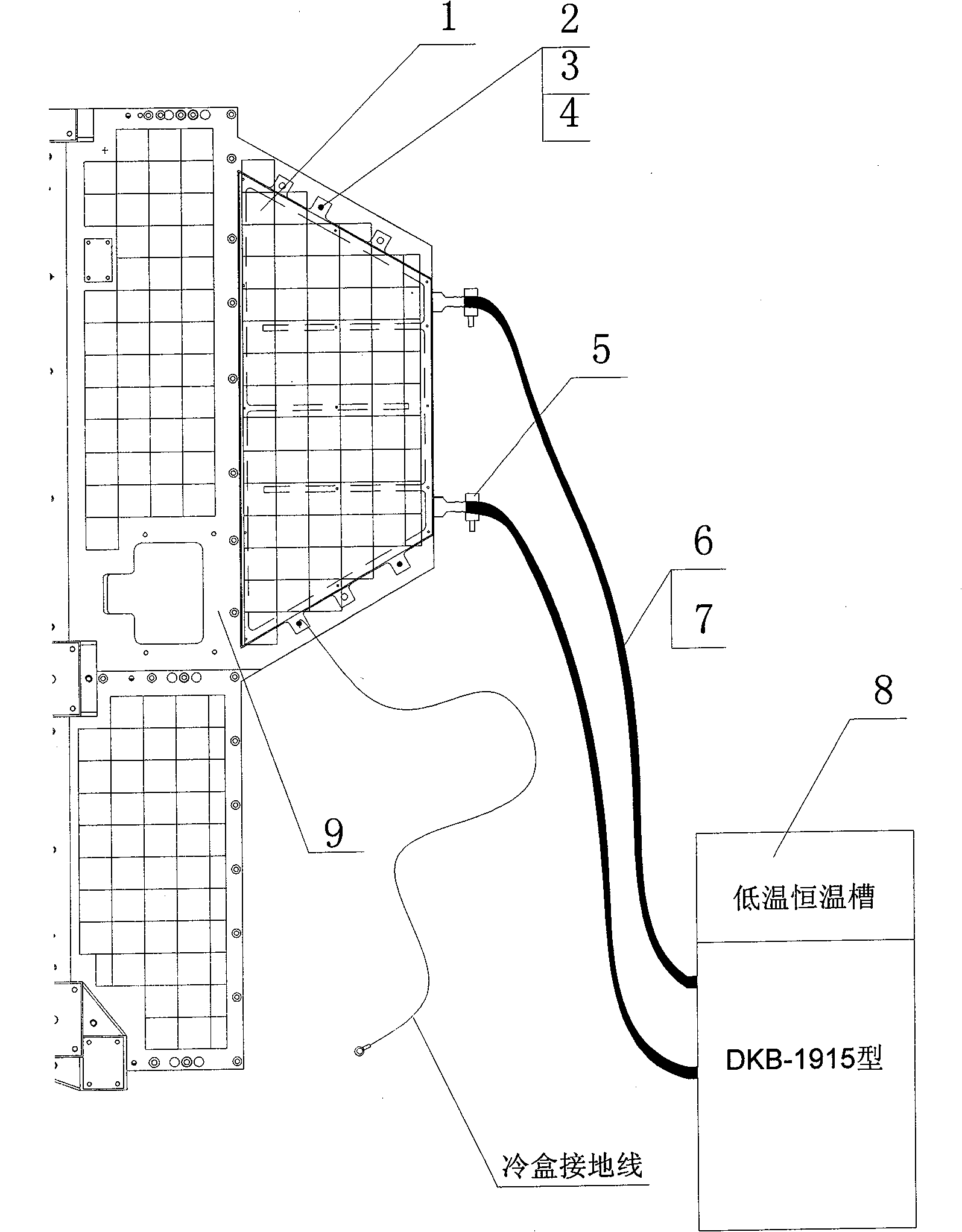

[0028] The battery cooling tool is composed of a cold box, a cold box connecting frame, an installation wrench, a screw, and a cooling medium. It is a necessary transitional cold source in the cooling system provided by this embodiment to quickly remove the heat from the battery on the heat expansion plate.

[0029] like figure 1 Shown, cold box is made of cold box bottom plate 1, cold box cover plate 2, cold box joint 3, joint nut 4, rubber washer 5, screw rod mounting hole insulating bushing 6 and insulating washer 7, compress insulating spacer 8 and It consists of a compression gasket 9, a thermally conductive rubber pad 10 and mounting fasteners 11, 12, 13, etc. The triangular cold box is made of aluminum plate, and the surface is anodized in natural color. Its shape is designed according to the shape of the heat expansion plate installed on the battery. The thickness of the bottom plate 1 of the box and the cover plate 2 of the cold box is 3 mm, and the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com