Blade cascade for a flow engine and flow engine comprising said blade cascade

A technology of fluid machinery and blades, which is applied in the field of fluid machinery cascades and fluid machinery with such cascades, which can solve the problems of suboptimal cascades and achieve the effects of improving efficiency and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

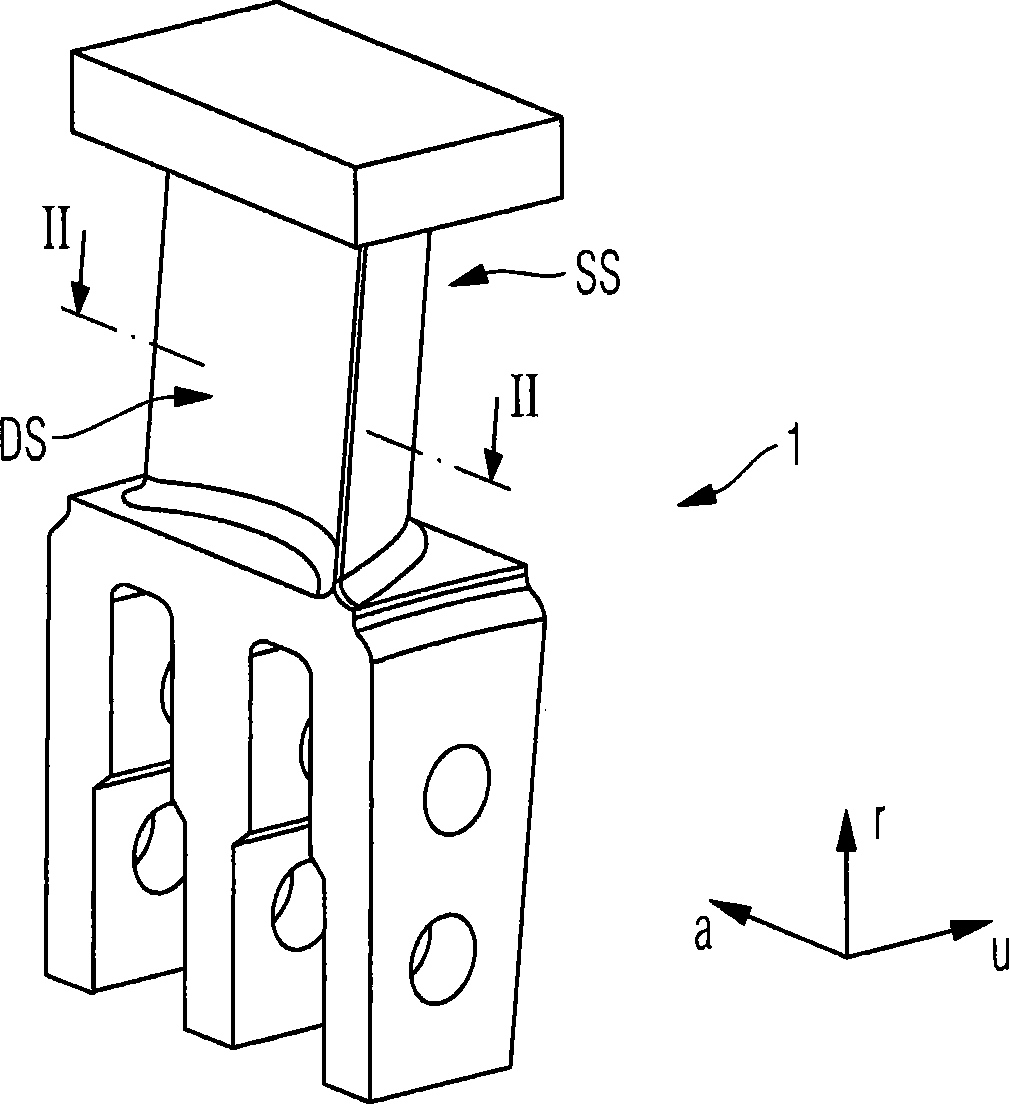

[0031] figure 1 Shown is a profiled rotor blade 1 of a cascade according to an embodiment of the invention with three-bladed pins. For orientation, the radial direction r, the circumferential direction U and the axial direction a are drawn.

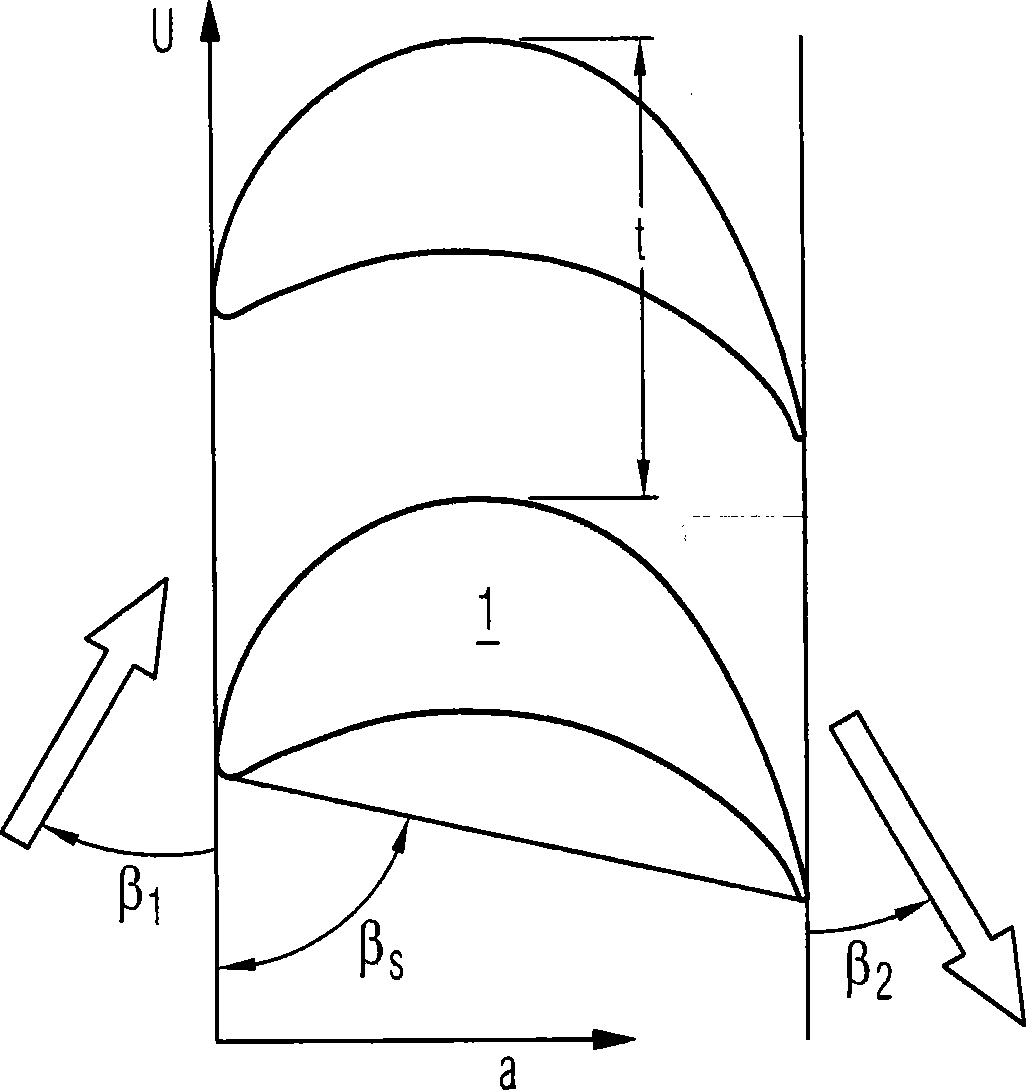

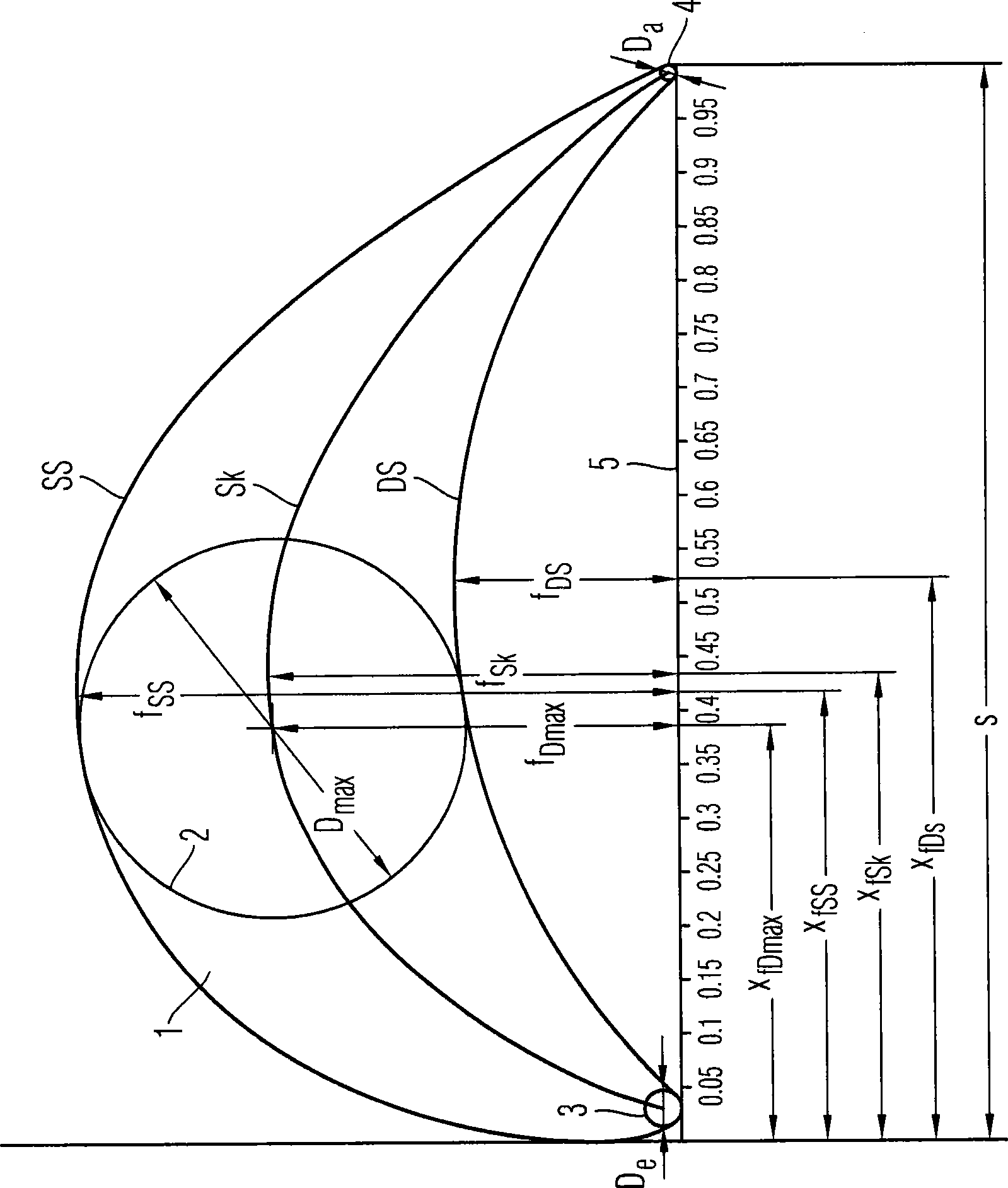

[0032] figure 2 shows the section II-II of the moving blade perpendicular to the radial direction r (compare figure 1 ), which includes the characteristic blade height and the characteristic blade circle in the double tangent system, the axis of the double tangent system and the axial direction or the circumferential direction correspondingly enclose the blade installation angle β which will be further explained below s . Here the first axis of the bitangent system (in figure 2 From left to right in the center)—the following dimension description refers to the double tangent system—parallel to the chord 5 of the moving blade 1, that is, tangent to the leading edge circle and the trailing edge circle 3, 4, the second axis (in figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com