Wheel motion assembly of city electric vehicle

A technology of electric vehicles and wheels, which is applied in the field of wheel assembly, can solve the problems of reducing passenger capacity, sacrificing stability, and safety, and achieves the effects of improving handling stability, shortening the development cycle, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

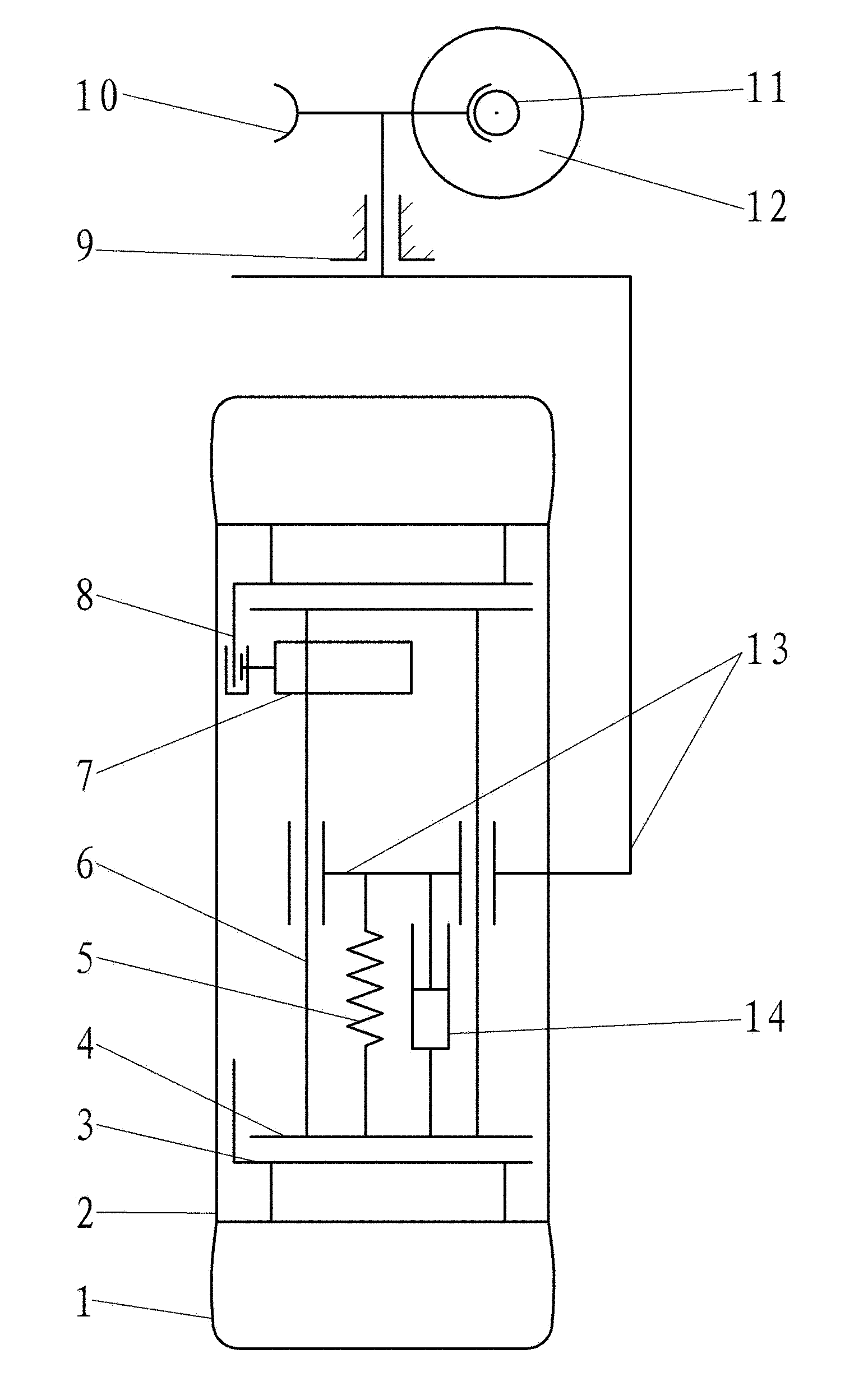

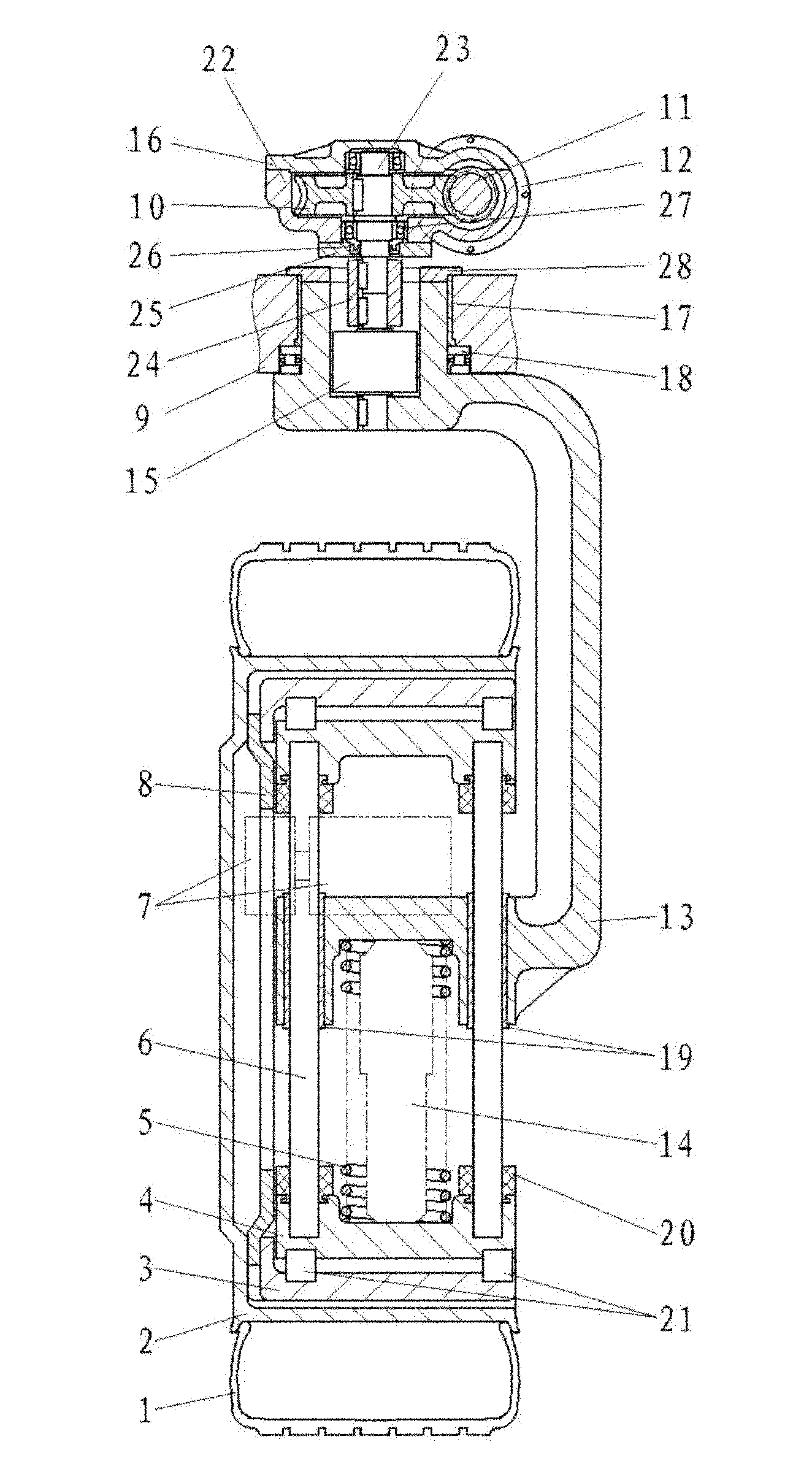

[0017] The present invention is described in detail below in conjunction with accompanying drawing:

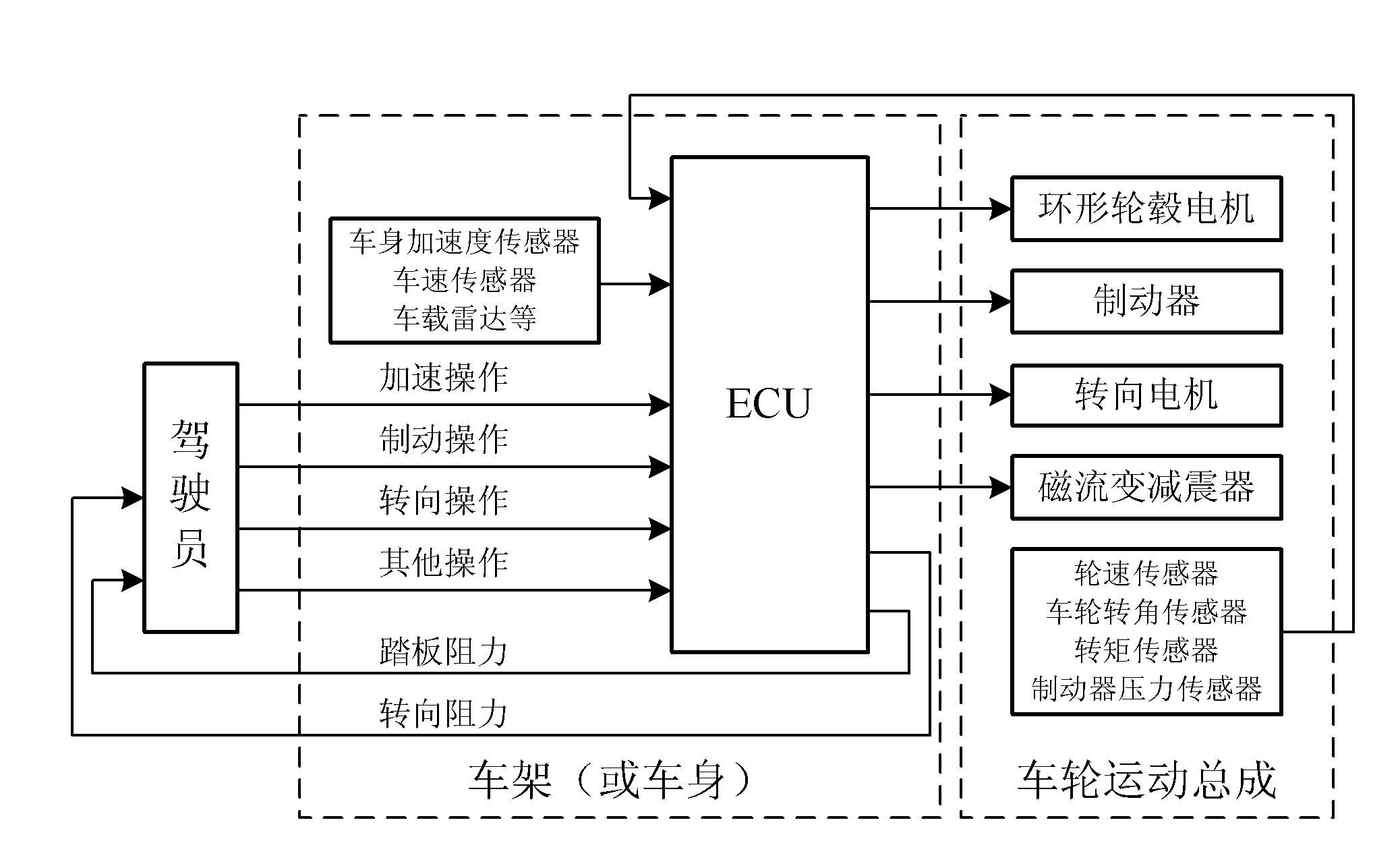

[0018] refer to figure 1 and figure 2 According to the invention, the wheel motion assembly of the urban electric vehicle includes wheels, ring hub motors, semi-active independent suspensions and actuators of the steering-by-wire system. The technical solution adopted in the present invention is to provide the driving force with the ring-shaped hub motor, and the reverse connection of the ring-shaped hub motor can also provide part or even all of the braking force. The output shaft of the steering gear drives all the components on the steering knuckle 13 to achieve a large angle or even 360° rotation. , the suspension is installed inside the annular hub motor to make the wheel and the annular hub motor jump relative to the steering knuckle 13 along the guide rod sliding bushing 19 .

[0019] The annular hub motor mainly includes the outer rotor 3 of the annular hub motor, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com