Composite grainy floor board sheet and manufacturing method thereof

A composite and floor sheet technology, applied to floors, layered products, buildings, etc., can solve the problems of poor air permeability, poor moisture-proof and anti-corrosion performance, and low anti-slip performance, and achieve good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

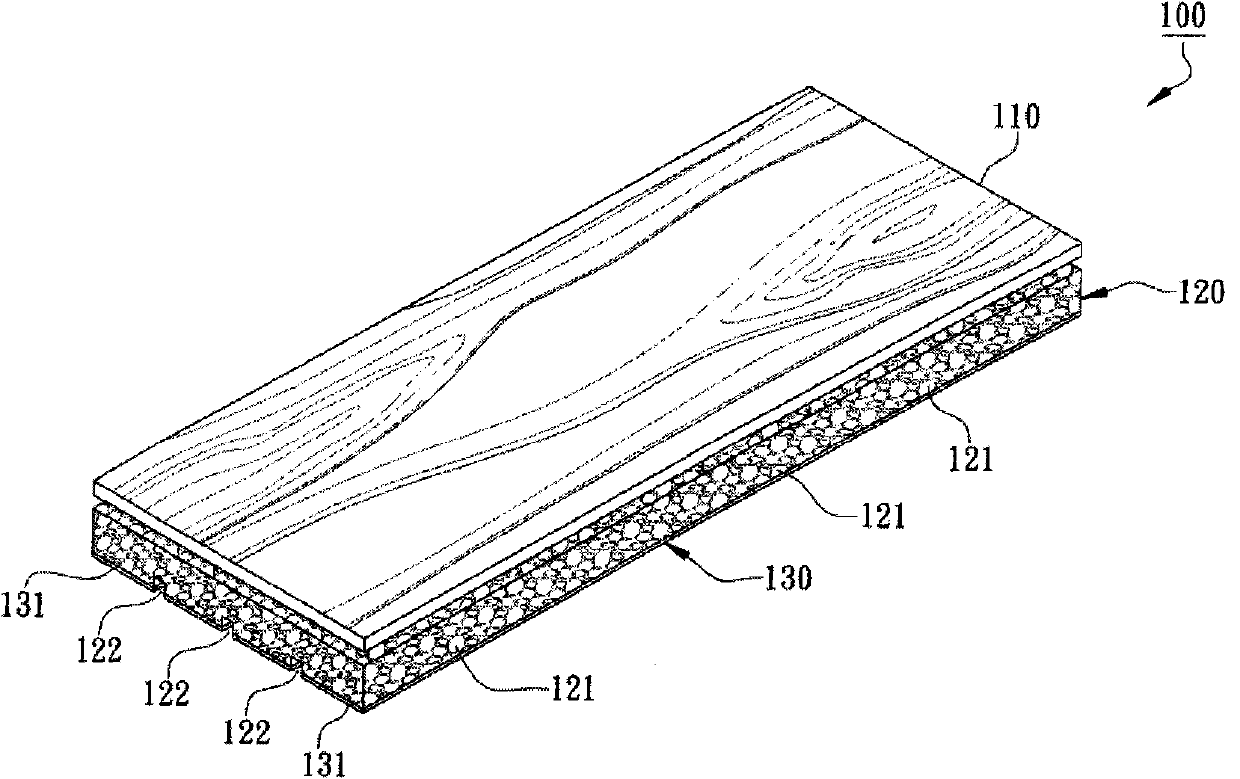

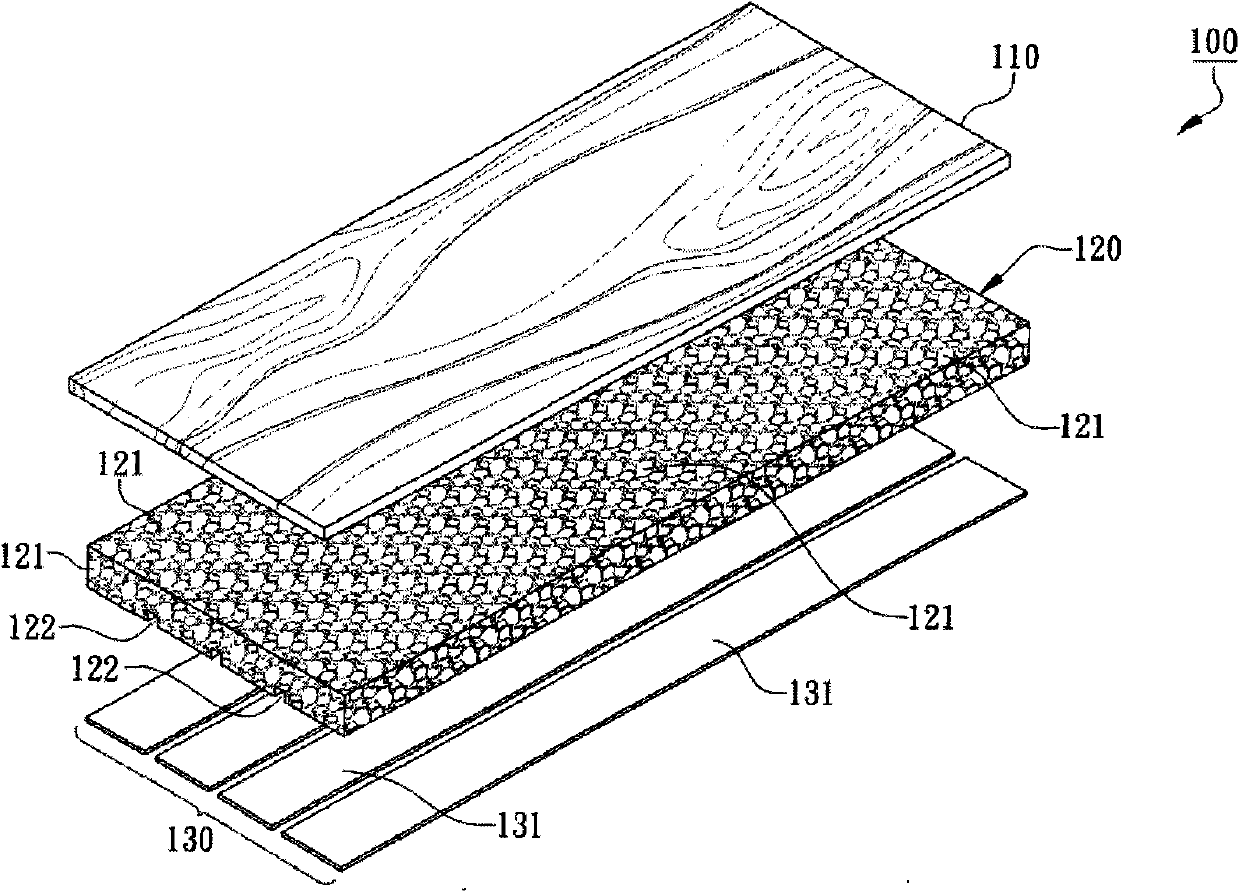

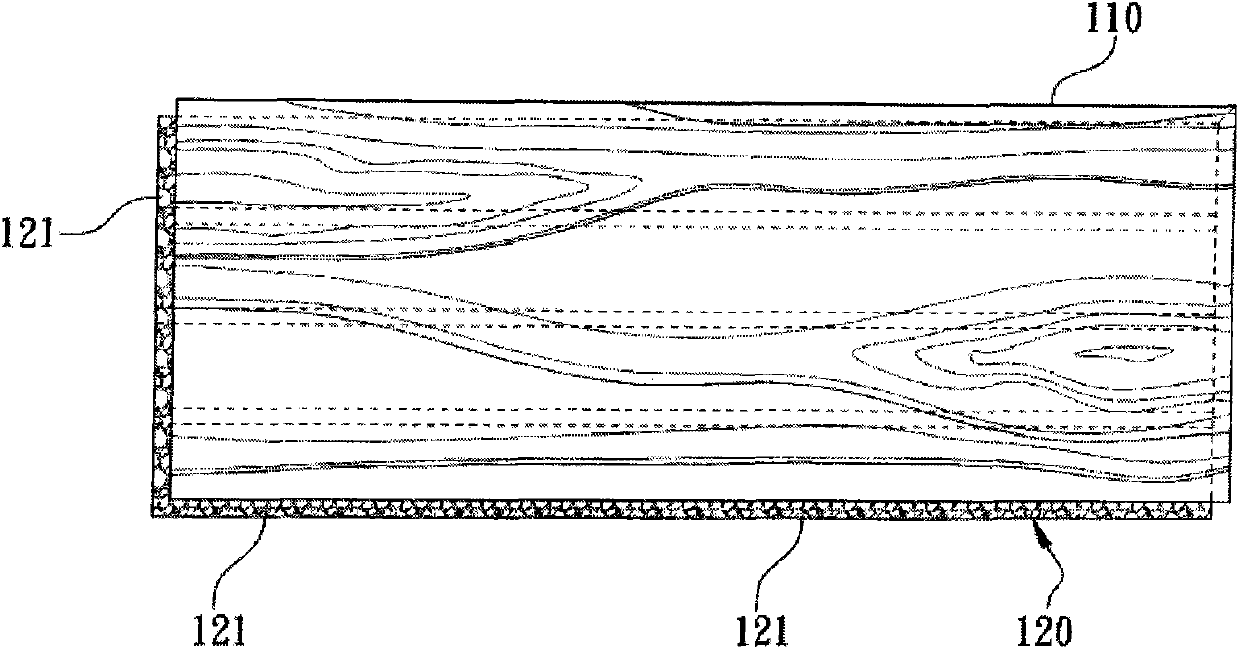

[0015] see figure 1 and figure 2 In the shown invention, a composite wood grain floor sheet 100 mainly includes a surface layer 110 , a base layer 120 and a bottom surface layer 130 . The surface layer 110 is used as a floor surface during installation. In this embodiment, the surface layer 110 has the same area and shape as the upper surface of the base layer 120, and the surface layer 110 is a solid wood board or a solid bamboo board, which is uniformly coated with a Latex is glued on the base layer 120 , and then processed by cold pressing, so that the surface layer 110 and the base layer 120 are closely bonded. In this embodiment, the surface layer 110 only accounts for 20% to 30% of the total thickness, which greatly saves forest resources, and the combination of the surface layer 110 and the base layer 120 realizes the organic fusion of wood and stone , in line with modern environmental protection requirements.

[0016] The base layer 120 is a volcanic rock plate, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com