Tin-plated steel plate and process for producing the tin-plated steel plate

A technology of tin-plated steel sheet and manufacturing method, which is applied in hot-dip plating process, coating of superimposed layers, phosphating, etc., can solve problems such as reduction of coating adhesion, failure to suppress deterioration of appearance, etc., and achieve low-cost chemical conversion Treatment, effect of suppressing deterioration of the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

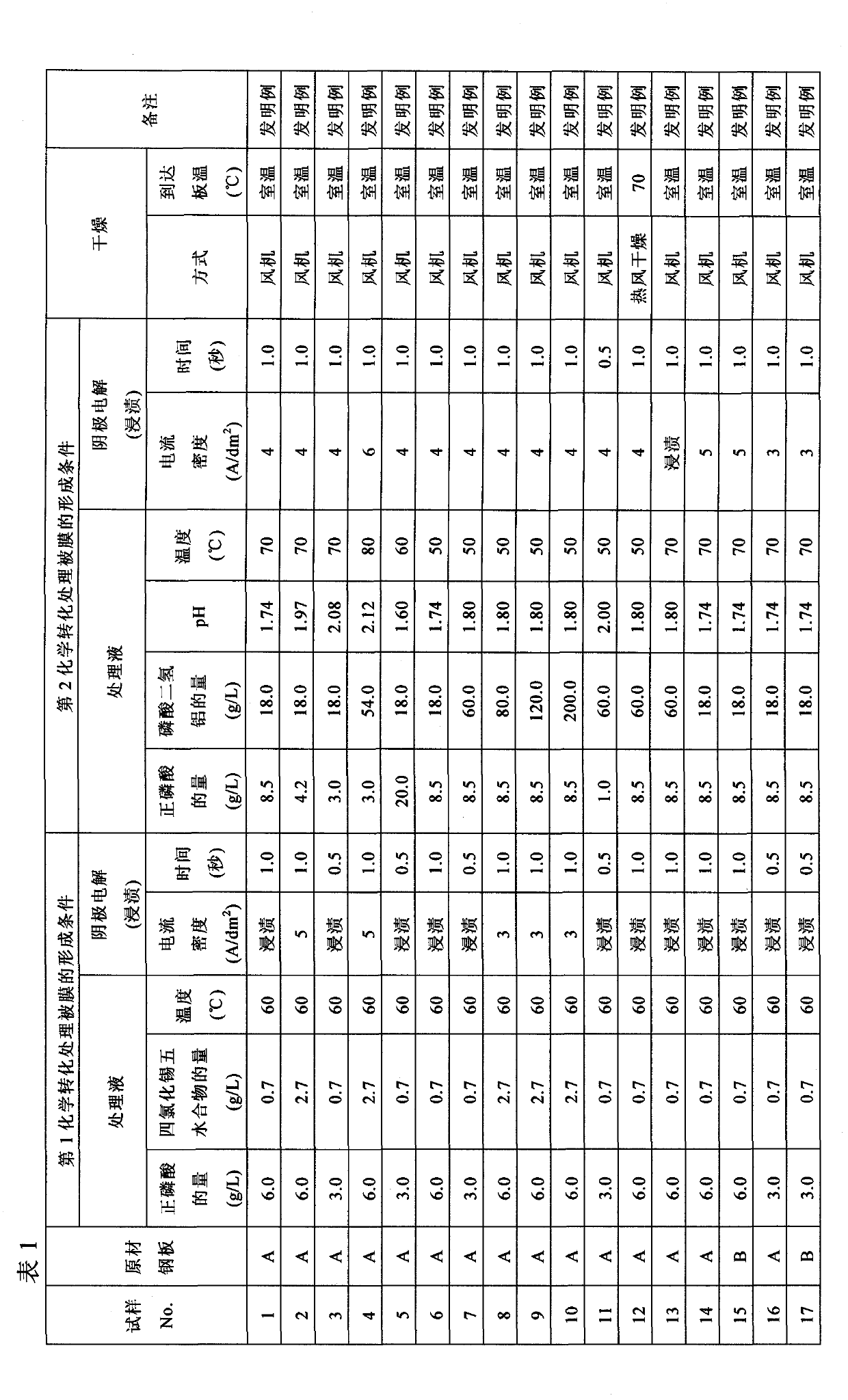

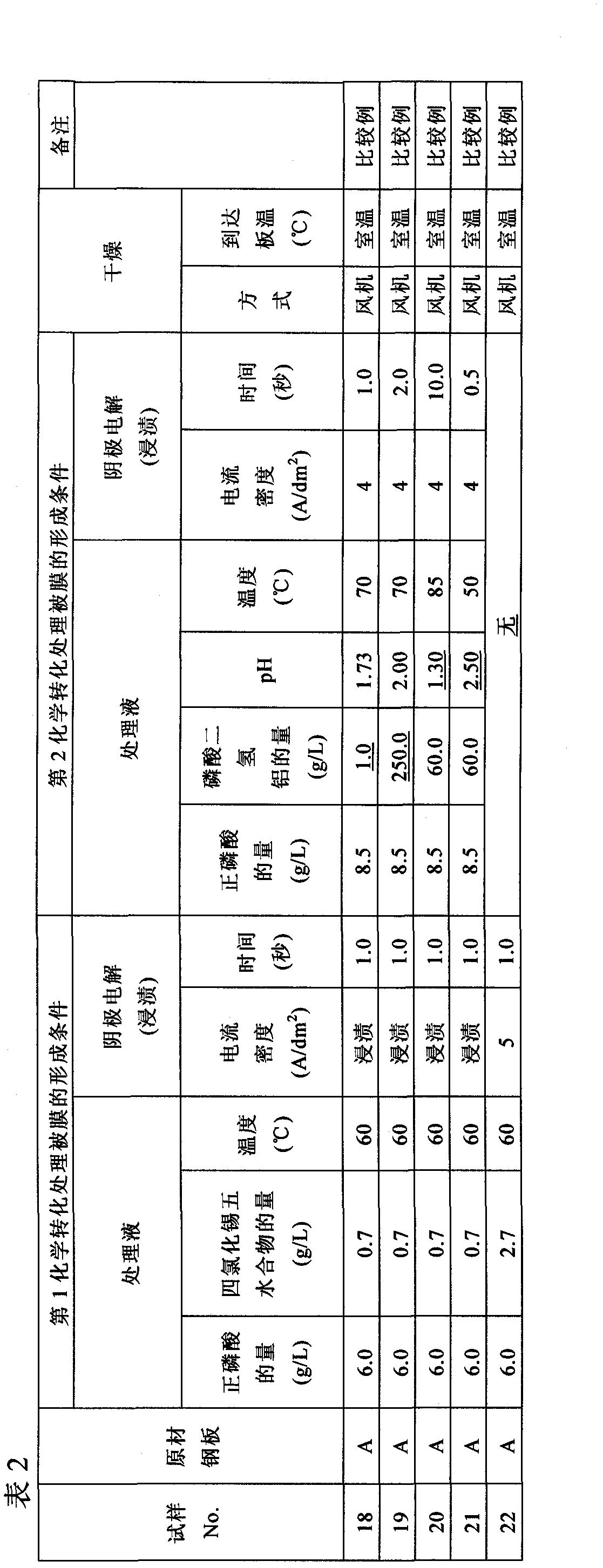

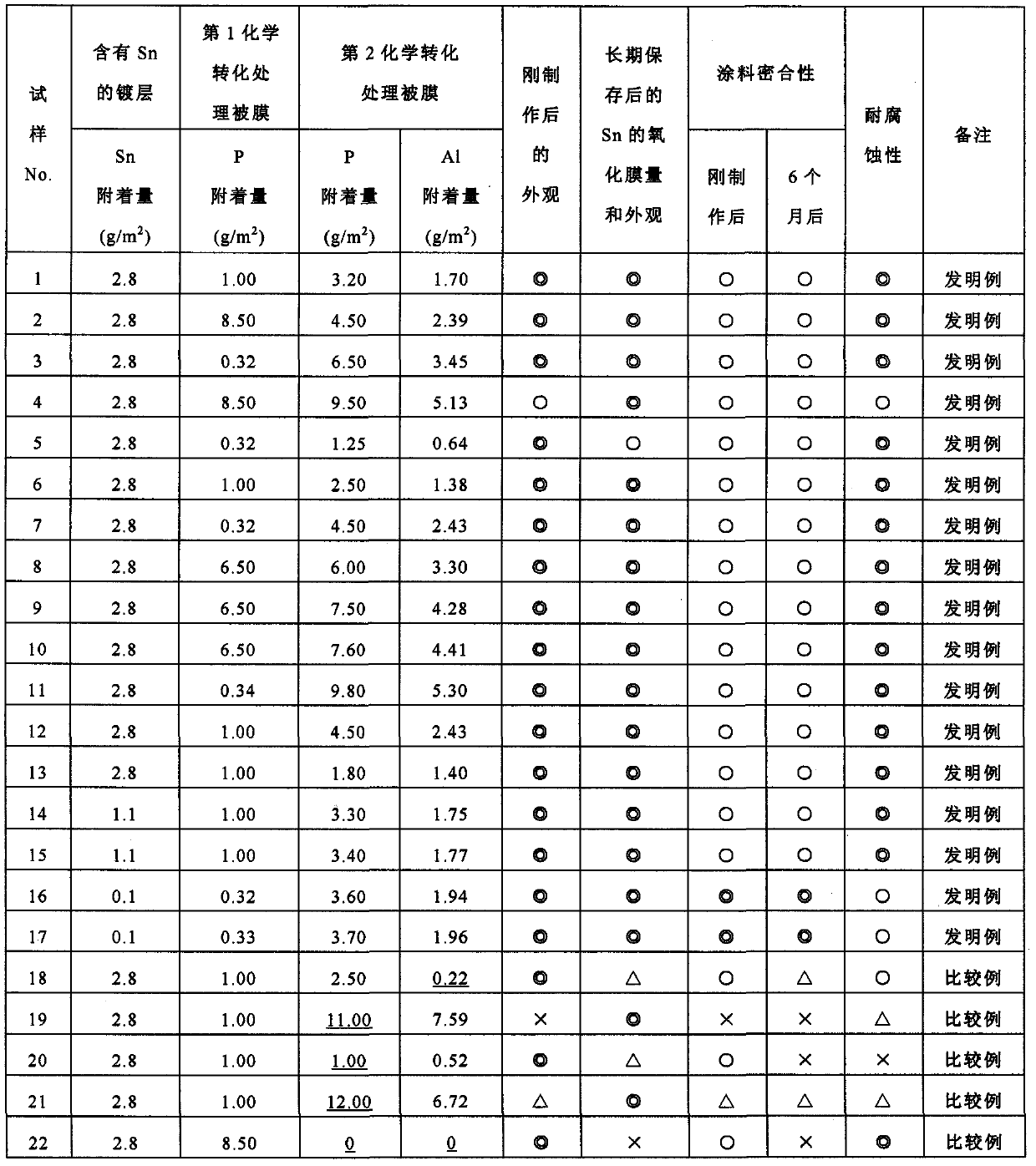

[0038] Using the following steel sheets as raw steel sheets, a commercially available tin plating bath was used to form a Sn layer according to the amount of Sn deposited on each surface shown in Table 3. After that, a reflow treatment was performed at a temperature above the melting point of Sn to form an Fe layer on the steel sheet A. - Sn-containing coating of Sn layer / Sn layer, and a Sn-containing coating of Fe-Ni layer / Fe-Ni-Sn layer / Sn layer is formed on steel plate B, wherein the above-mentioned original steel plate is steel plate A: plate thickness 0.2 mm low-carbon cold-rolled steel plate, or steel plate B: 100 mg / m per surface using a Watt bath 2 The amount of adhesion is to form a nickel coating on both surfaces of a low-carbon cold-rolled steel sheet with a thickness of 0.2 mm, and then, in 10 volume% H 2 +90vol%N 2 A steel plate that is annealed at 700°C in an atmosphere to diffuse and infiltrate the nickel coating.

[0039] Then, in order to remove the Sn oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com