Method for performing quick decomposition and returning treatment on left stubbles of field straws

A processing method and straw technology, which are applied in the fields of land preparation methods, biological sludge treatment, agricultural machinery and equipment, etc., can solve the problems of restricting the application and popularization of straw returning machinery, clogging, and low efficiency of straw decomposing and returning to the field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

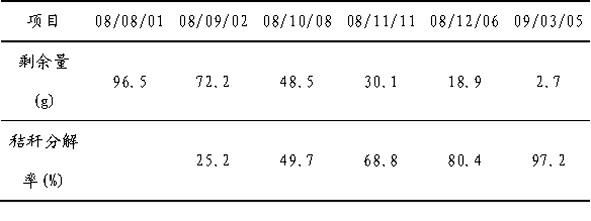

Embodiment 1

[0016] Embodiment 1: A method for quickly decomposing and returning field straw stubble to the field, comprising the following steps:

[0017] 1) Activation of the rot agent: divide the rot agent made of 40% yeast, 35% fermented filamentous bacteria and 25% photosynthetic bacteria into two parts, the first part of the rot agent and water The blending ratio is 1:600; the blending ratio of the second stalk rot agent to water is 1:300; the two stalk rot solutions mixed with water are respectively activated at 38°C for 10 hours;

[0018] 2) Use the combined operation machine for straw returning to the field and pesticide spraying to remove the stubble remaining in the field. The height of the stubble removal in the field is 10 to 12 cm; at the same time, spray the first part of humus agent solution described in step 1, and then remove the stubble that has been removed. Stay in the field for 1.5 days; the rotten agent solution mixed with the first part of the rotten agent and water...

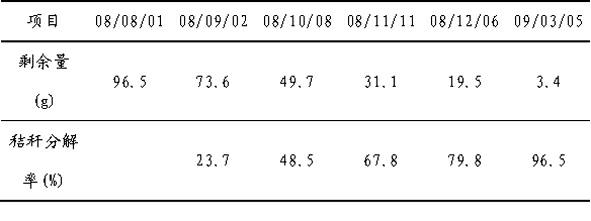

Embodiment 2

[0025] Embodiment 2: A method for quickly decomposing and returning field straw stubble to the field, comprising the following steps:

[0026] 1) Activation of the rot agent: divide the rot agent made of 40% yeast, 35% fermented filamentous bacteria and 25% photosynthetic bacteria into two parts, the first part of the rot agent and water The blending ratio is 1:500; the blending ratio of the second stalk rot agent and water is 1:200; the two stalk rot solutions mixed with water are respectively activated at 35°C for 12 hours;

[0027] 2) Use the combined operation machine for straw returning to the field to remove stubble from the stubble remaining in the field. The stubble height of the stubble in the field is 9-11 cm; at the same time, spray the first part of the humic agent solution described in step 1, and then remove the stubble that has been stubbled. Stay in the field for 2 days; the first stalk rot solution mixed with water is 200L / hm 2 spraying;

[0028] 3) Use the ...

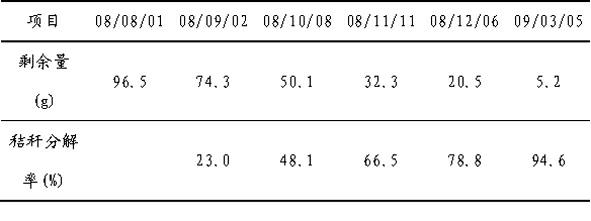

Embodiment 3

[0034] Embodiment 3: A method for quickly decomposing and returning field straw to the field, comprising the following steps:

[0035] 1) Activation of the rot agent: divide the rot agent made of 40% yeast, 35% fermented filamentous bacteria and 25% photosynthetic bacteria into two parts, the first part of the rot agent and water The blending ratio is 1:700; the blending ratio of the second part of rotten agent to water is 1:400; the two parts of rotten agent solution mixed with water are respectively activated at 35°C for 8 hours;

[0036] 2) Use the combined operation machine for straw returning to the field and pesticide spraying to remove the remaining stubble in the field, and the height of the stubble removal in the field is 10-15 cm; at the same time, spray the first part of humus agent solution described in step 1, and then remove the stubble that has been removed. Stay in the field for 1 day; the first rot rot solution mixed with water is 250L / hm 2 spraying;

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com