Automatic cleft grafting machine for nursery stock

A grafting machine, automatic technology, applied in horticulture, application, botanical equipment and methods, etc., can solve the problems of limited promotion and application, low degree of automation, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

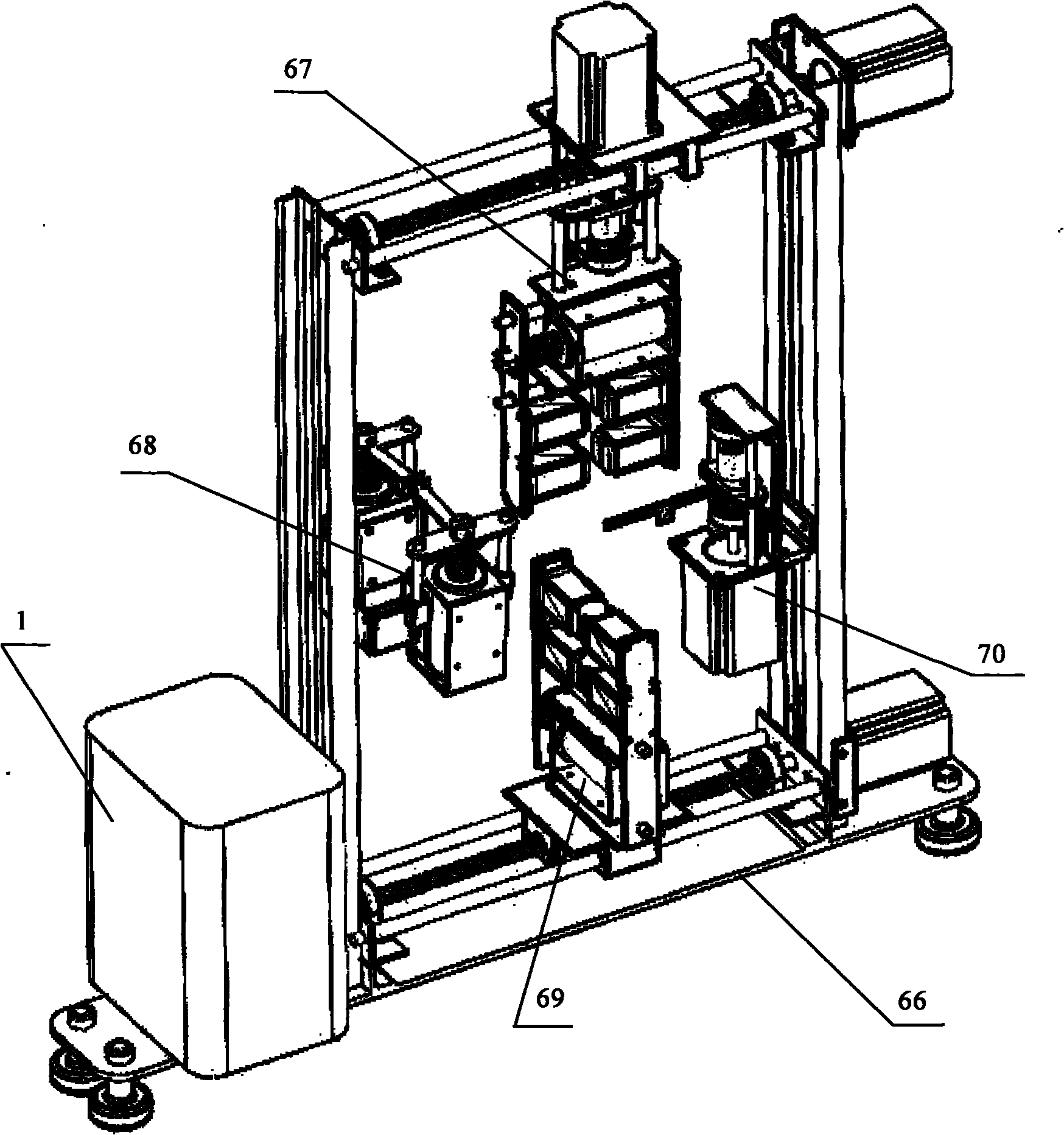

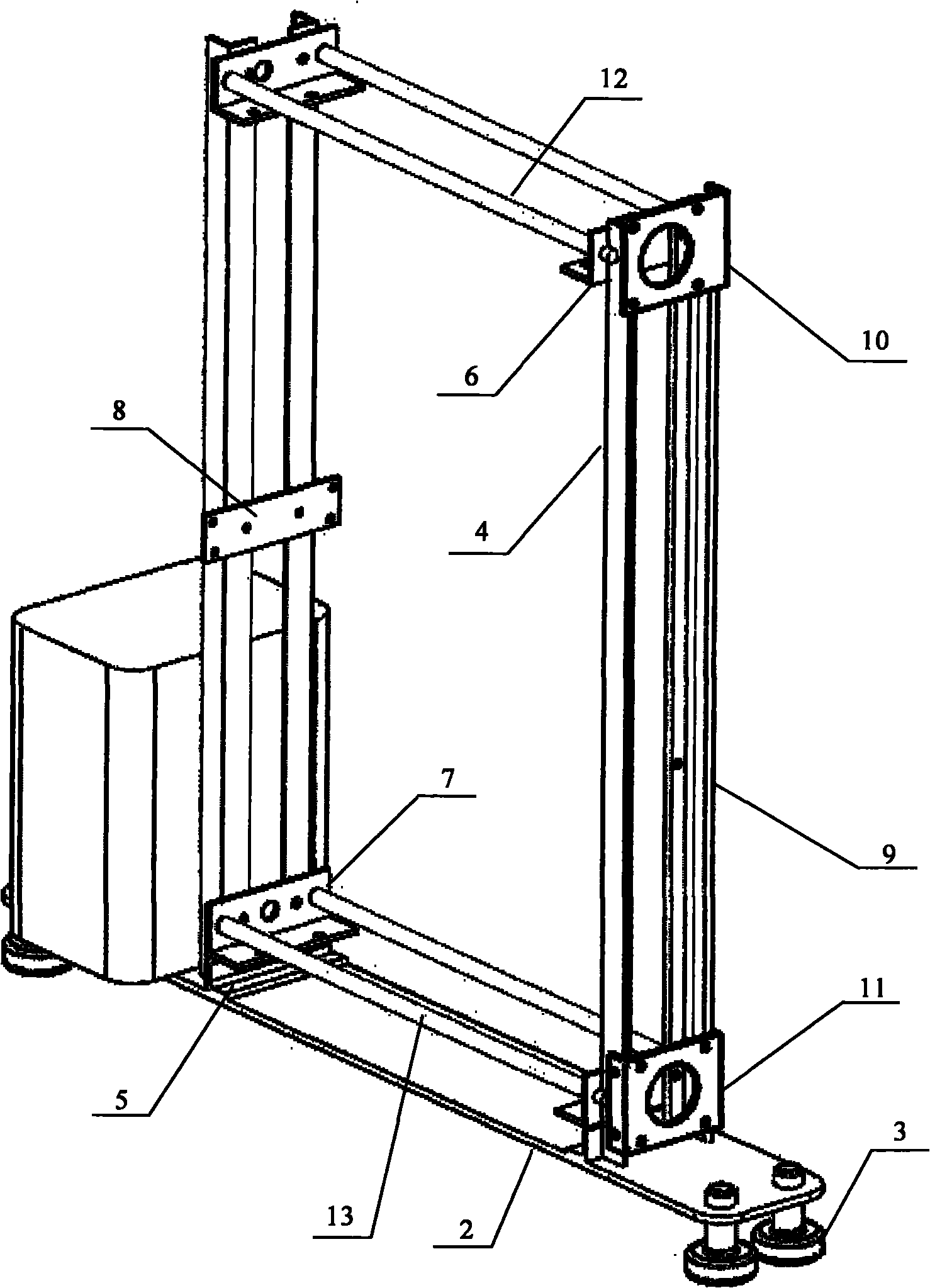

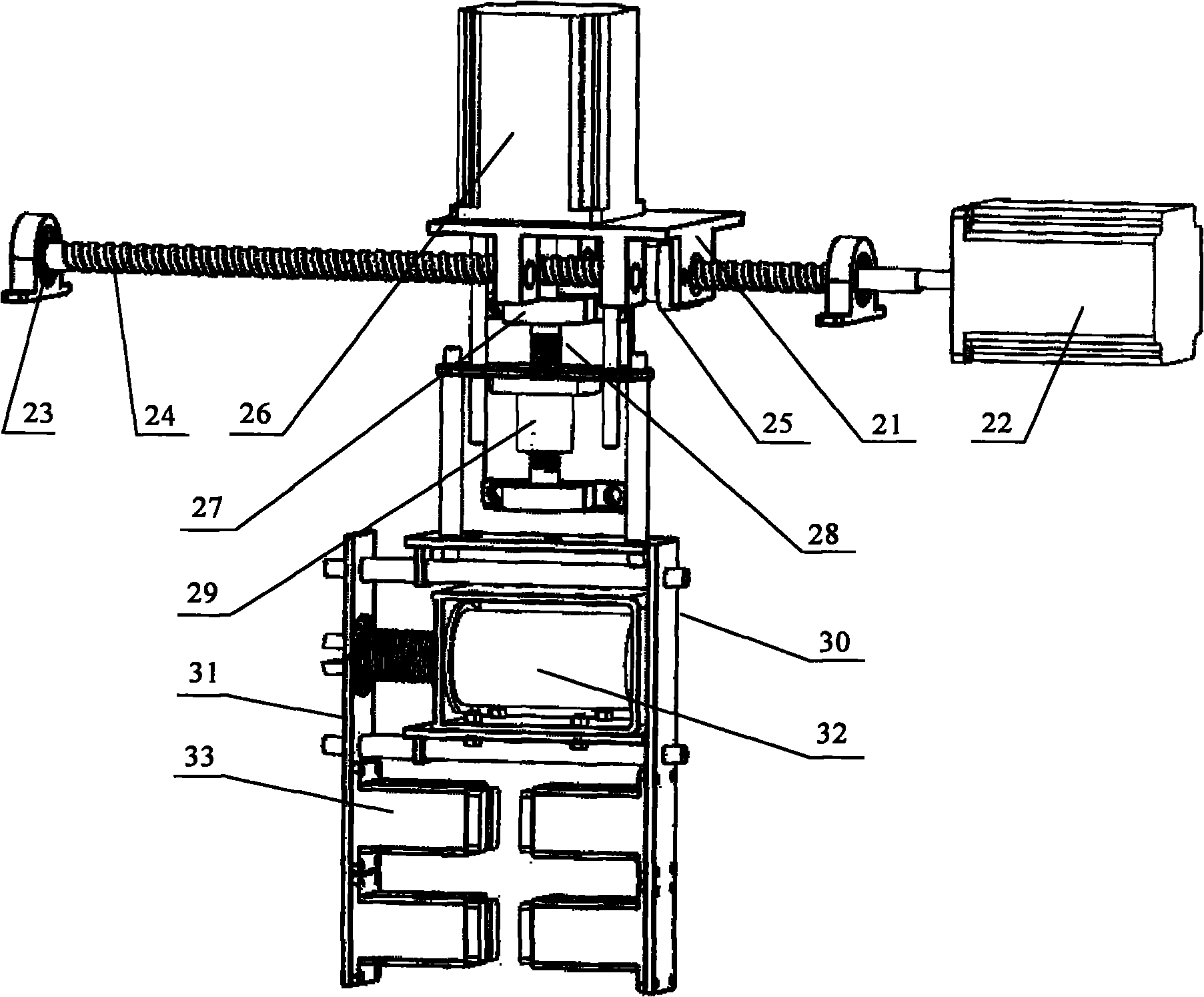

[0030] According to an embodiment of the present invention, an automatic splitting and grafting machine for seedlings is provided. Such as Figure 1-Figure 6 As shown, the present embodiment includes: a frame assembly 66 equipped with an upper moving slide rail 12 and a lower moving slide rail 13; It is used for clamping and fixing during the conveying, cutting and joining of earwood seedlings; the earwood cutting mechanism 68 is installed on the left support plate assembly of the frame assembly 66, and consists of two earwood cutting assemblies symmetrically arranged front and back , used to complete the cutting operation of the wedge-shaped incision of the ear st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com