Stainless steel water window structure of water jug

A stainless steel and water window technology, which is applied to the transformation of the existing kettle water window structure, in the field of stainless steel kettle water window structure, can solve the problems that the water window is easily affected by deformation, high requirements for plastic parts, complex assembly process, etc., and achieves a simple structure , high production efficiency and simple assembly process

Active Publication Date: 2011-06-15

谛卓(北京)咨询顾问有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the assembly buttons of this structure are all set on the water window cover and water window seat made of plastic, the water window is easily affected by deformation, the requirements for plastic parts are relatively high, and the assembly process is relatively complicated, the production efficiency is low, and it is scrapped. high rate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

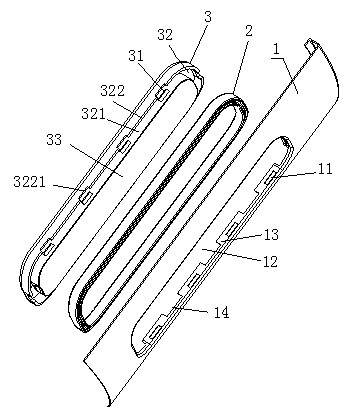

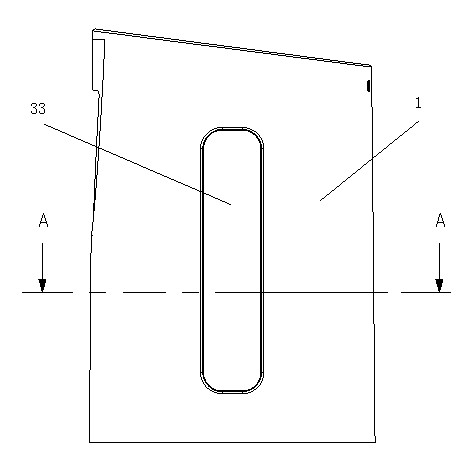

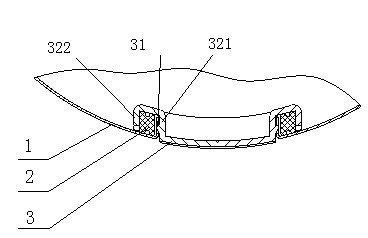

The invention relates to a stainless steel water window structure of a water jug. The water window structure comprises a water window, a jug body and a seal ring, wherein the jug body is provided with a through hole for mounting the water window, and the seal ring is arranged between the water window and the jug body. The water window structure is characterized in that the water window is positioned in the through hole on the jug body and is connected with the jug body through a buckle structure. Compared with the prior art, the water window structure provided by the invention has the advantages that a plastic water window seat is omitted, instead the water window and the jug body are directly connected and fixed, and the structure is simple; and snap assembling is not the port assembling of a plastic water window cover and a rubber water window seat, but the mutual buckling of the plastic water window and the stainless jug body, has less possibility of being influenced by deformation, and the assembling process is quite simple, the production efficiency is high, the rejection rate is reduced more than 10%, and the cost is lowered by about 10%.

Description

A stainless steel kettle water window structure technical field The invention relates to a water window structure of a kettle, in particular to a water window structure of a stainless steel kettle, which belongs to the modification technology of the existing water window structure of a kettle. Background technique The water window is a necessary structure for visually observing the water level in the kettle with an opaque body, such as a stainless steel kettle. At present, the structure of the water window of this type of kettle includes a kettle body with openings, a water window seat arranged on the edge of the opening of the kettle body, a water window cover, a sealing ring arranged between the water window seat and the water window cover, and the water window cover. The window cover is assembled from the outside of the kettle body and buckled into the water window seat on the edge of the opening on the kettle body, so as to achieve a sealing effect. However, the assem...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): A47J36/00A47J27/21

Inventor 杨宗海

Owner 谛卓(北京)咨询顾问有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap