Fiber transmission automatic laser welding system dedicated for plate type solar thermal collector

A solar heat collector and optical fiber transmission technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult welding technology, high welding operation and precision requirements, and achieve compact structure and convenient The effect of high operation and welding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

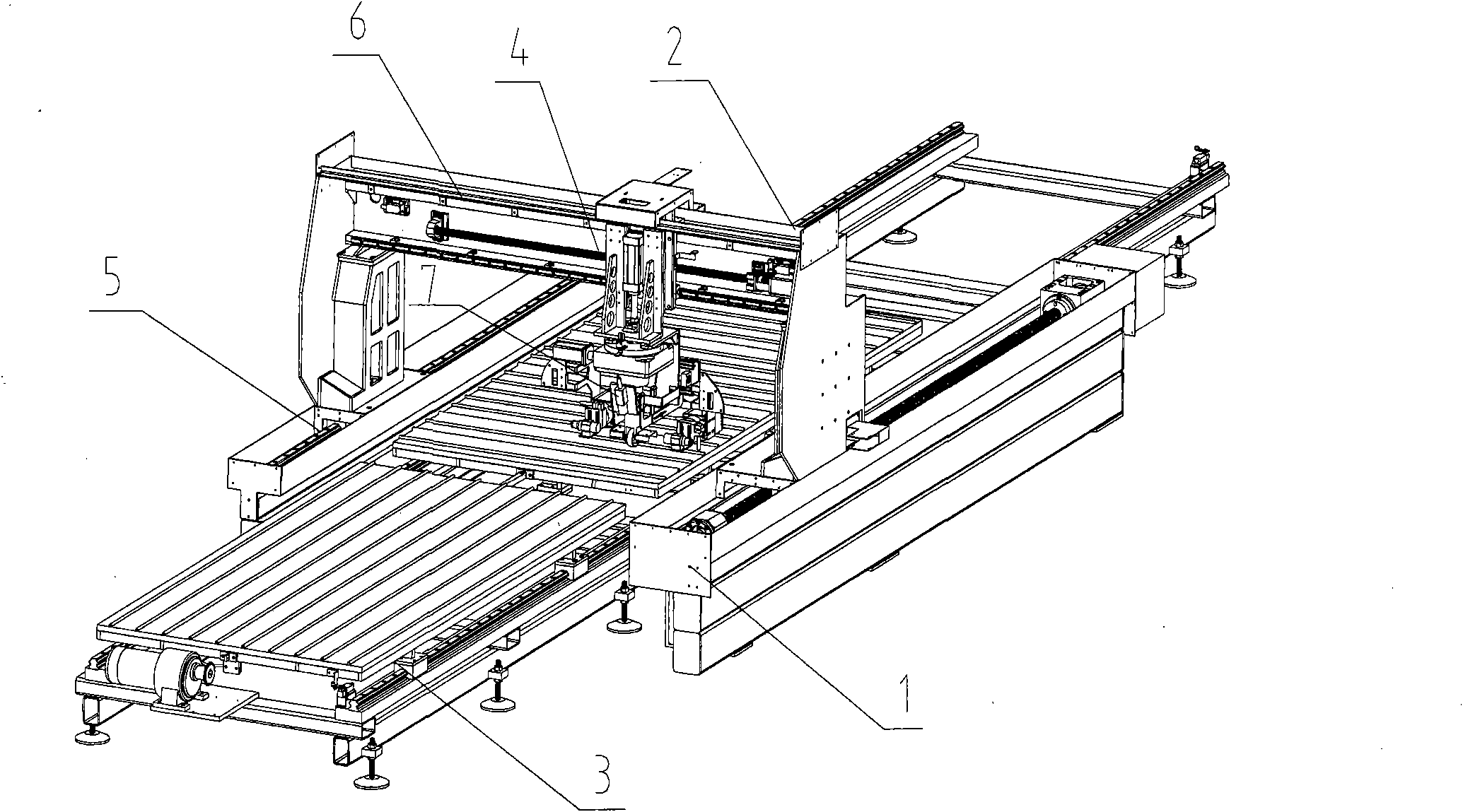

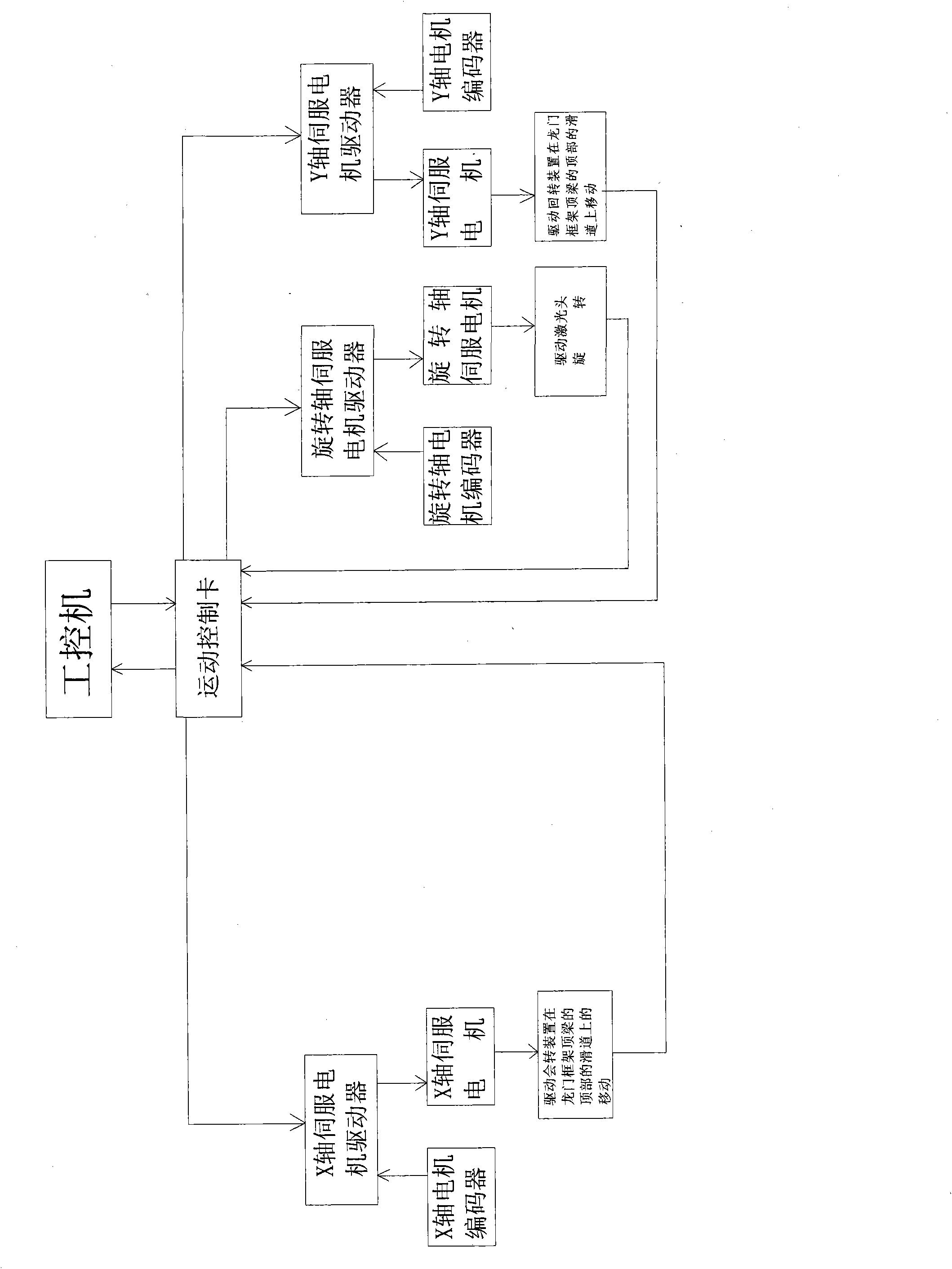

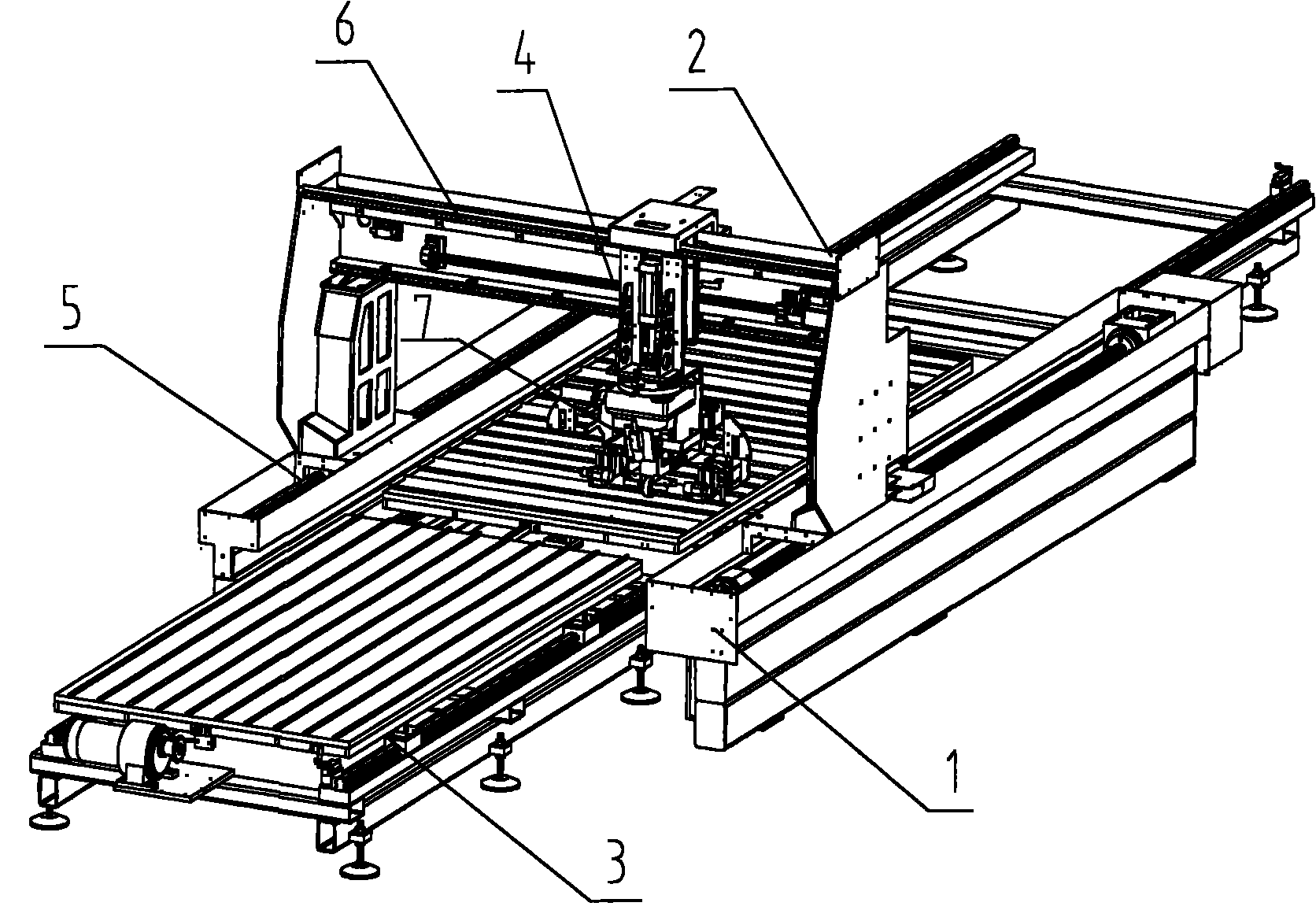

[0013] see figure 1 , an optical fiber transmission automatic laser welding system dedicated to plate solar collectors of the present invention consists of a base 1, a gantry frame 2, an exchangeable workbench 3, a rotary device 4, a CCD visual tracking device 7, and a control device, wherein , the two laser heads are connected with the rotary device 4 through the rotating shaft, the rotary device 4 is suspended on the slideway at the top of the top beam of the gantry frame 2, the CCD vision tracking device is closely connected with the laser head and the small Y axis, the two of the gantry frame 2 The end is supported on the slideways on the top of both sides of the base 1, and the conveyor belt in the center of the base is a workbench for placing the plate solar collector. The conveyor belt is also equipped with an exchangeable workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com