Large-scale reflex kinematic machine tool drive device

A driving device and reciprocating technology, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems that restrict the development of large machine tools, achieve good environmental protection effects, improve manufacturing accuracy, and save hydraulic oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

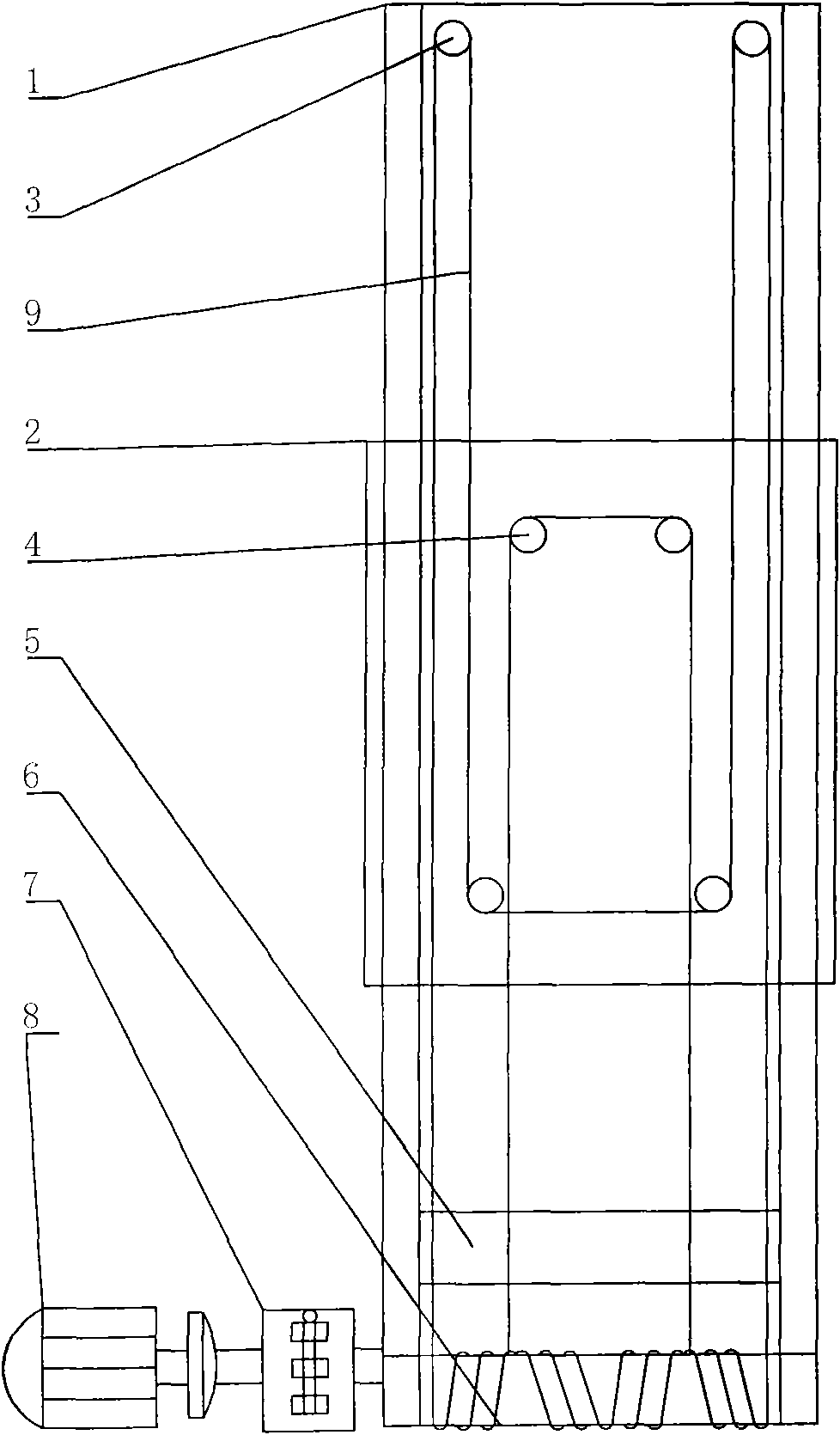

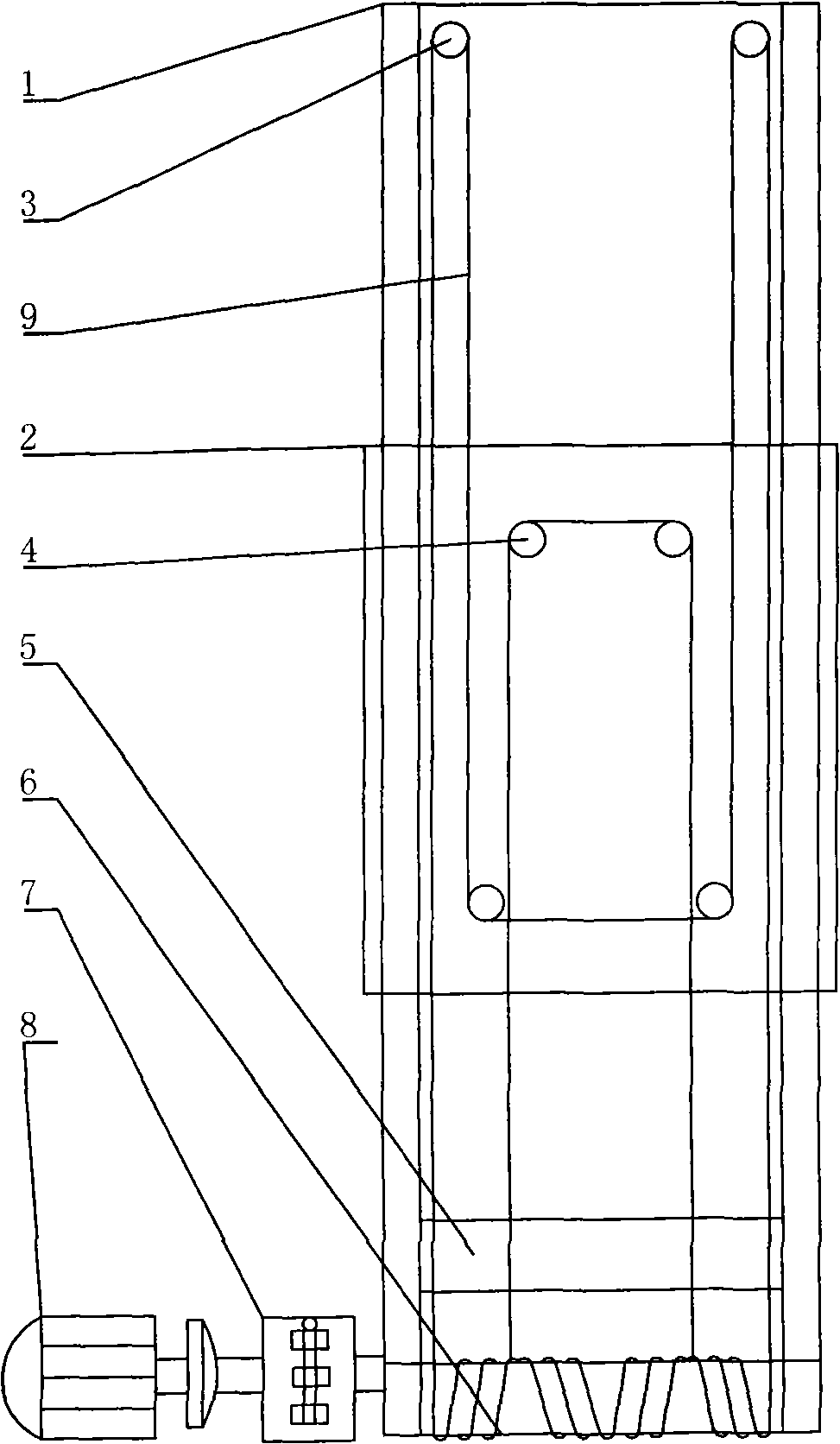

[0012] A driving device for a large reciprocating motion machine tool, which includes a machine bed frame 1 and a machine bed 2, such as figure 1 As shown: a fixed pulley 3 with a powerful point is fixed on one end of the above-mentioned machine bed frame 1, a bed fixed pulley 4 is evenly distributed on the machine bed 2, and a supporting roller 5 and a hoisting roller are fixed on one end of the above-mentioned machine bed frame 1. Bucket 6, hoisting drum 6 is equipped with speed change mechanism 7 and speed regulating motor 8 in turn, above-mentioned power point fixed pulley 3, bed fixed pulley 4 and hoisting drum 6 are all wound with steel wire rope 9, above-mentioned power point fixed pulley 3 There are two symmetrically arranged on both sides of one end of the machine tool bed frame 1 , and four of the bed frame fixed pulleys 4 are evenly distributed in the middle of the machine tool bed 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com